High performance pre-embedded steel anchor plate

A high-performance, pre-embedded technology, applied in the direction of structural elements, building components, building reinforcements, etc., can solve the problems of weld damage, anchor reinforcement stress, etc., to save materials, reduce construction difficulty, and reasonable force transmission Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

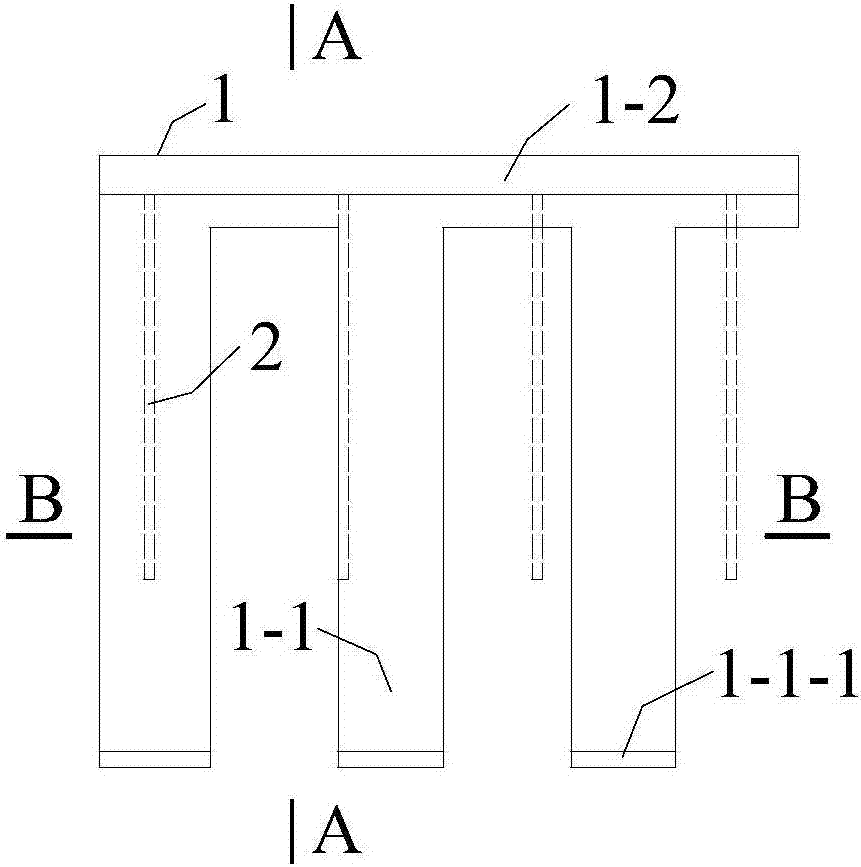

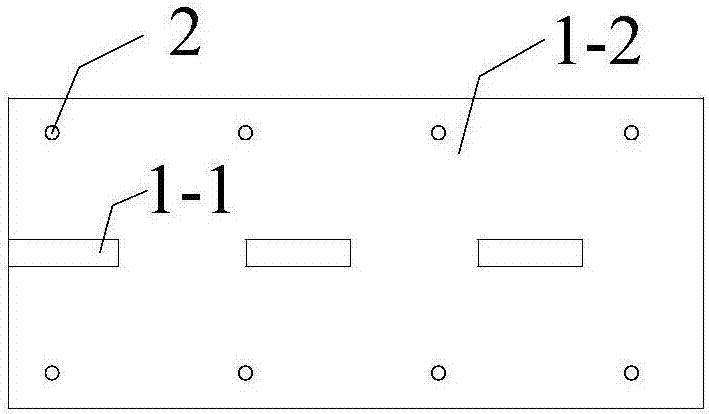

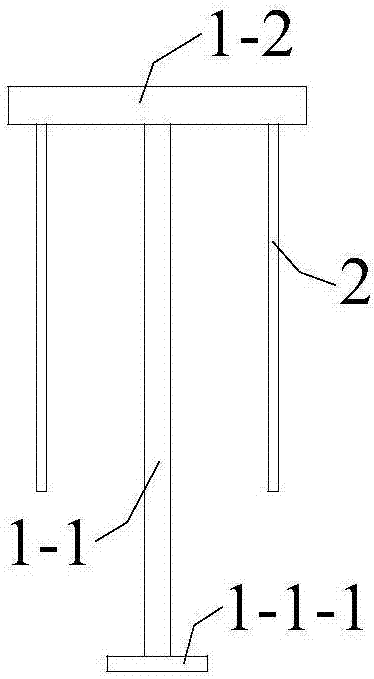

[0030] Such as Figure 1~4 Shown: a high-performance pre-embedded steel anchor plate, including a toothed T-shaped plate 1 and anchor bars 2, the web of the toothed T-shaped plate 1 is tooth-shaped with equal width, and the gap between the two teeth can penetrate The width of the single tooth is smaller than the net spacing of the stirrups, and the anchor bar 2 is welded to the flanges on both sides of the web of the toothed T-shaped plate 1; the toothed T-shaped plate 1 adopts a rectangular cut 3 The web of the I-shaped steel is cut in dislocation to ensure that the tooth web 1-1 of the toothed T-shaped plate 1 and the flange 1-2 are integrated to avoid welding, and the toothed web 1-1 of the toothed T-shaped plate 1- The end of 1 is welded vertically to the lower anchor plate 1-1-1.

Embodiment 2

[0032] Such as Figure 5 As shown: this embodiment is the same as the rest of embodiment 1, except that the end of the tooth web 1-1 is bent to form an L-shaped anchor head 1-1-2.

Embodiment 3

[0034] Such as Image 6 As shown: this embodiment is the same as the rest of embodiment 1, the difference is that the tooth webs 1-1 of the toothed T-shaped plate 1 are not equal in width, and the cutting seam 3 is a trapezoidal line, which is wide at the top and narrow at the bottom. cross-sectional form.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com