Fume leakage preventing structure of integrated stove

An integrated stove, leak-proof technology, applied in the field of integrated stove, can solve the problems of body pollution, oil flow obstruction, cleaning, maintenance trouble, etc., and achieve the effect of solving oil leakage and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

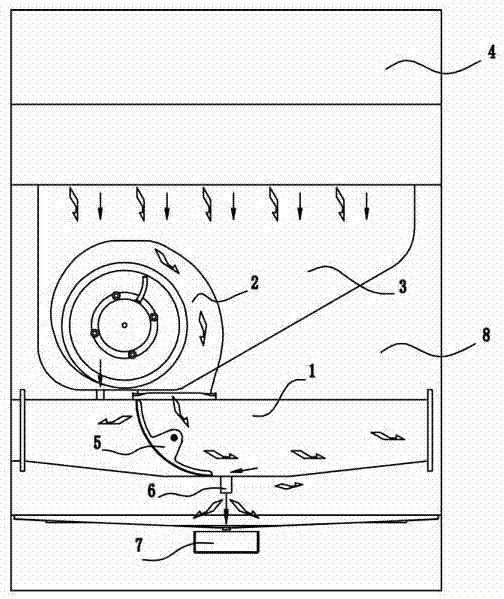

[0022] Embodiment one, such as figure 2 As shown, in the anti-leakage smoke structure of the integrated cooker of the present invention, the chimney 1 is a cuboid cavity, the upper end of the chimney 1 is connected to the air outlet of the fan 2, the bottom of the chimney 1 is provided with an oil leakage hole 6, and there is an oil collection box below the oil leakage hole 6 7. There is also an arc-shaped smoke guide plate 5 inside the chimney. The smoke guide plate 5 is close to the upper wall, front wall, and rear wall of the chimney 1 and guides the air outlet of the fan 2, separating the chimney 1 into the working area and the waiting area. In the two areas of the working area, a soot gap 9 is provided between the bottom end of the smoke guide plate 5 and the bottom wall of the chimney 1, and its height is 5-20mm. During work, the oily fume is inhaled from the smoke collecting hood 4, enters the chimney 1 through the smoke collecting chamber 3 and the fan 2, and is guide...

Embodiment 2

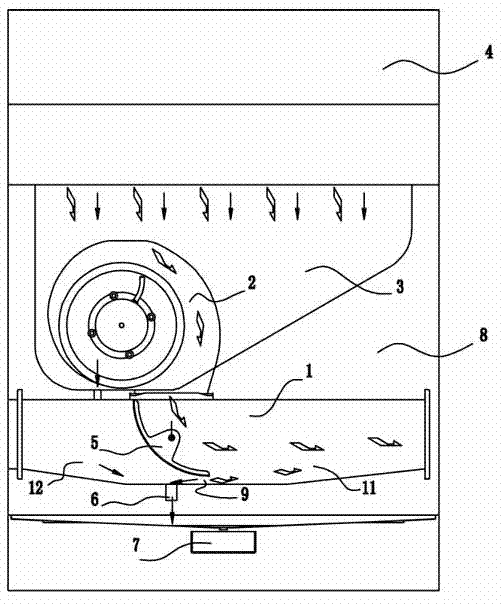

[0023] Embodiment 2. For the convenience of installation, the direction of smoke exhaust can be selected. The smoke guide plate 5 can be turned around its axis to support the replacement of the smoke exhaust port. The oil leakage hole 6 of the chimney 1 is set at the position below the smoke guide plate 5. In the direction of the axis of the smoke guide plate 5.

Embodiment 3

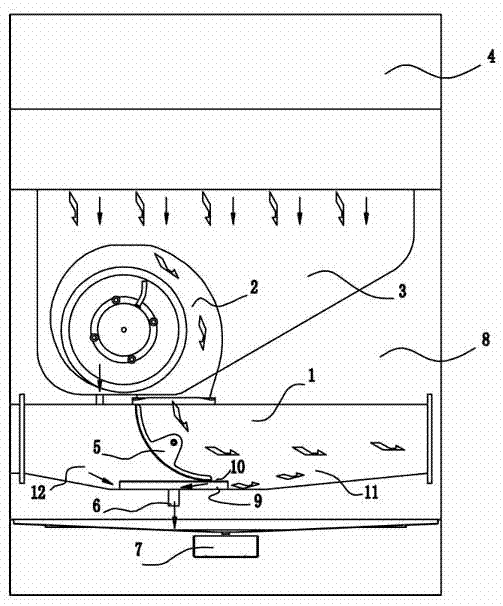

[0024] Embodiment three, such as image 3 As shown, the anti-leakage smoke structure of the integrated cooker of the present invention, compared with Embodiments 1 and 2, further includes a deflector 10, and the deflector 10 is located between the bottom end of the smoke guide 5 and the bottom wall of the chimney. above the oil fume gap 9, the deflector 10 is connected to the front wall and the rear wall of the chimney 1, the bottom end of the smoke deflector 5 is close to the deflector 10, and the smoke deflector 5 and the deflector 10 together The chimney 1 is divided into a positive pressure working area 11 and a negative pressure waiting area 12 , and the oil leakage hole 6 is located below the deflector 10 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com