A monitoring device and its scheme for a crane heave compensation device

A technology of heave compensation and crane, which is applied in the direction of measuring devices and instruments, can solve problems such as damage, mechanical structure fatigue, excessive buckling, etc., and achieve the effects of high measurement accuracy, simple and convenient maintenance, and instant feedback

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

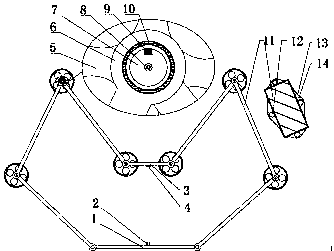

[0031] The present invention will be further described below in conjunction with accompanying drawing

[0032] Such as figure 1 , a crane heave compensation device monitoring system, characterized in that: 1 position sensor unit: a lower support rod (1), a laser distance sensor (2) installed on the upper side of the lower support rod (1), an upper support frame ( 3), the laser distance sensor reflection device (4) installed on the lower side of the upper support frame (3); 2 pressure-speed sensor unit: turntable (5), connecting rod rocker (6), connected to the turntable (5) Shaft (7), axial center pressure sensor (8) placed in the middle of shaft (7), magnetoresistor speed sensor (9), magnetoresistor speed sensor matching part (10); 3-link stress and strain measurement unit: connected rod (11), fiber grating sensor (12), heat shrink tube (13), filling resin (14) wrapped on the fiber grating sensor (12), the resin prevents the fiber grating sensor from being polluted or damage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com