Displacement controlled micro thin plate bending rigidity measurement device and working method thereof

A measuring device and displacement control technology, applied in the direction of using a stable bending force to test the strength of materials, etc., can solve the problems of unfavorable factory mass production inspection whether the rigidity meets the requirements, high equipment and test site requirements, and complex test methods. Achieve the effect of rapid measurement, easy maintenance and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

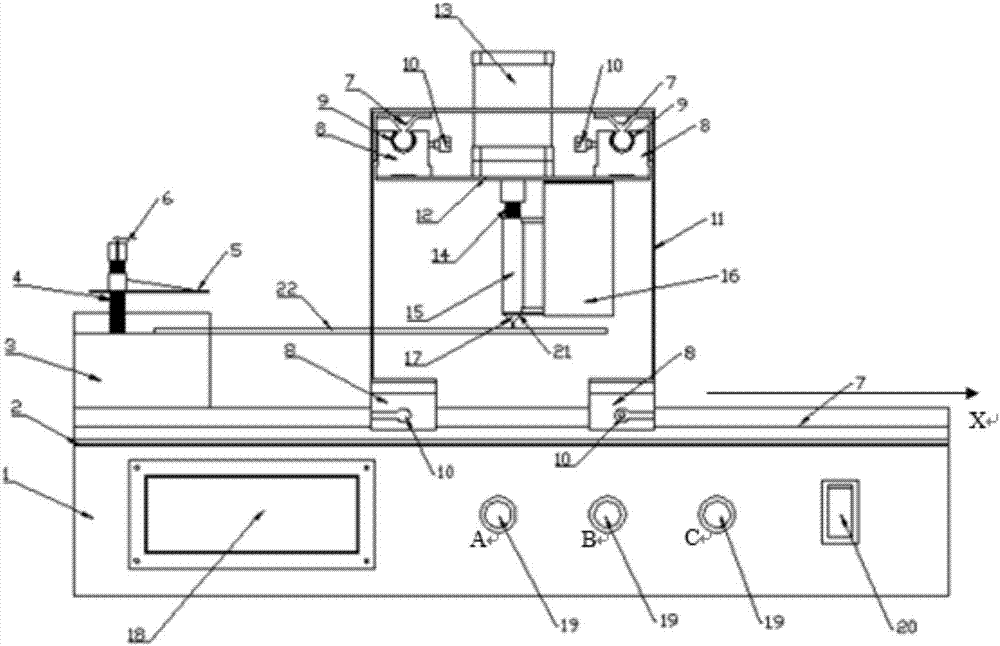

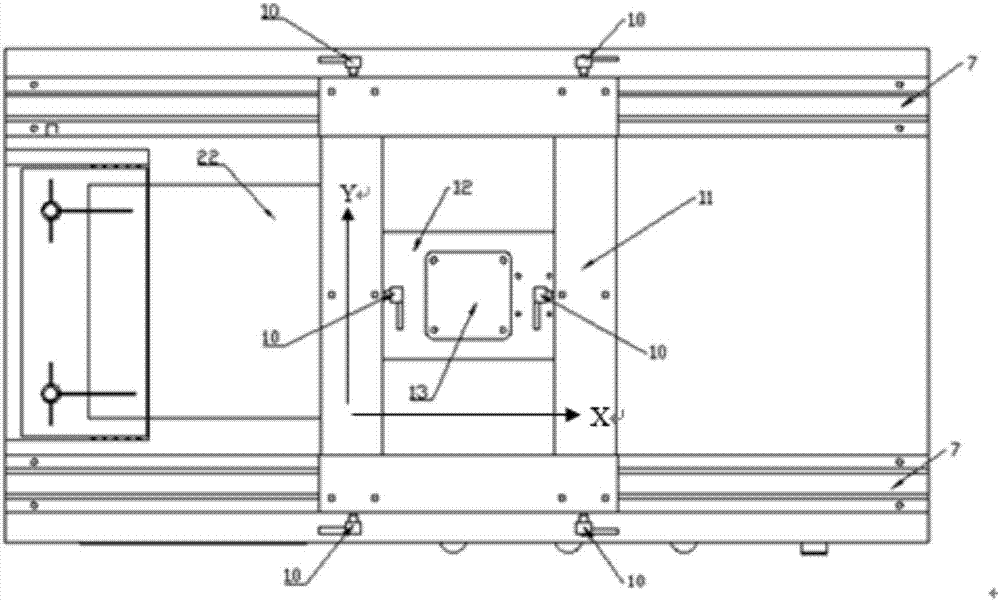

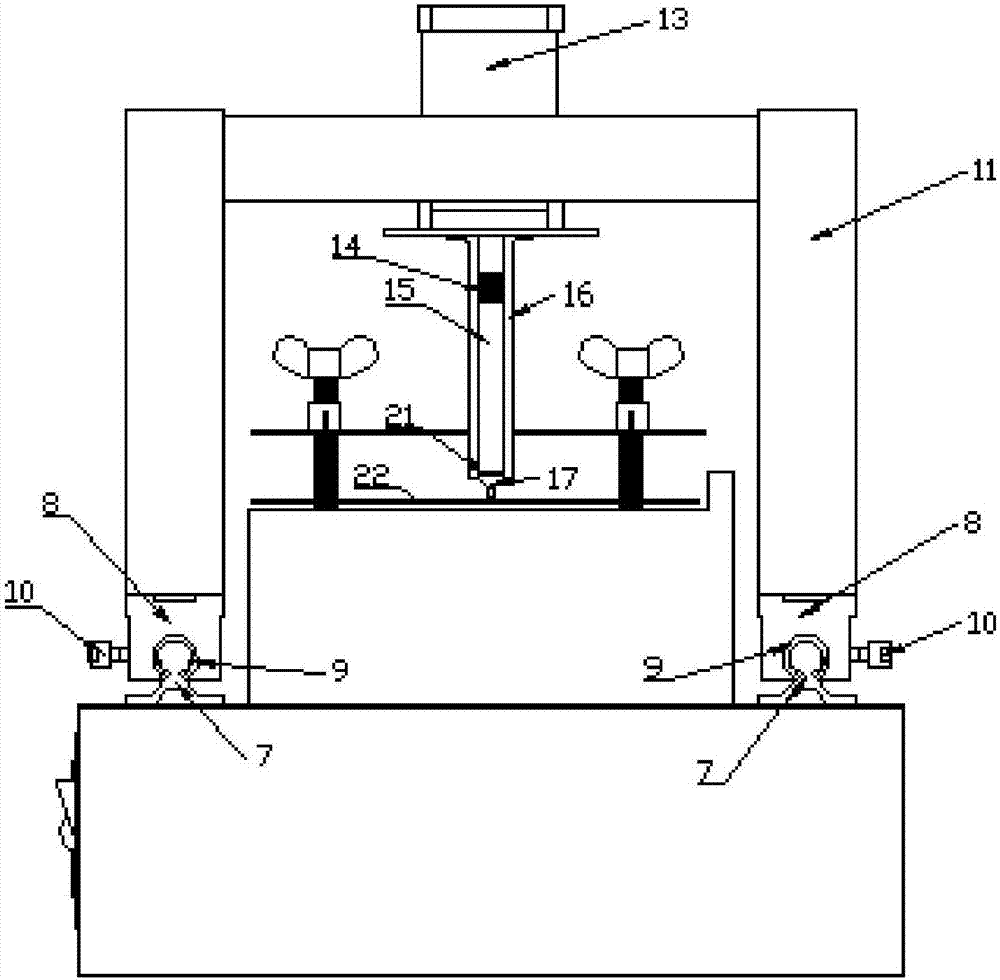

[0038] The present invention will be further described below in conjunction with the accompanying drawings.

[0039] The invention discloses a displacement-controlled miniature sheet bending stiffness measuring device, which comprises: a base, a test piece, a test piece clamping device, a measuring point positioning device, a measuring device, a signal processing device, and an operation and display device.

[0040] The base comprises a cuboid box-shaped base 1 with an upper opening and a base cover plate 2, which are connected by screws.

[0041] The specimen clamping device is composed of a clip 3, a clip 5, a stud 4 and a nut 6, wherein the clip 3 and the base cover 2 are connected by bolts, and the stud 4 and the clip 3 are connected by threads. The test piece 22 is placed horizontally on the clamp block 3, the contact length between the test piece 22 and the clamp block 3 in the long side direction is 9-10 mm, the opening of the clamp piece 5 passes through the stud 6, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com