An accessory device and application method for ceramic ball rolling friction test

A rolling friction and ceramic ball technology, which is applied in the field of material friction, can solve the problems of ceramic ball clamping and single size of auxiliary fixtures, etc., and achieve the effect of compact structure, wide application range and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with accompanying drawing, the present invention is described in further detail:

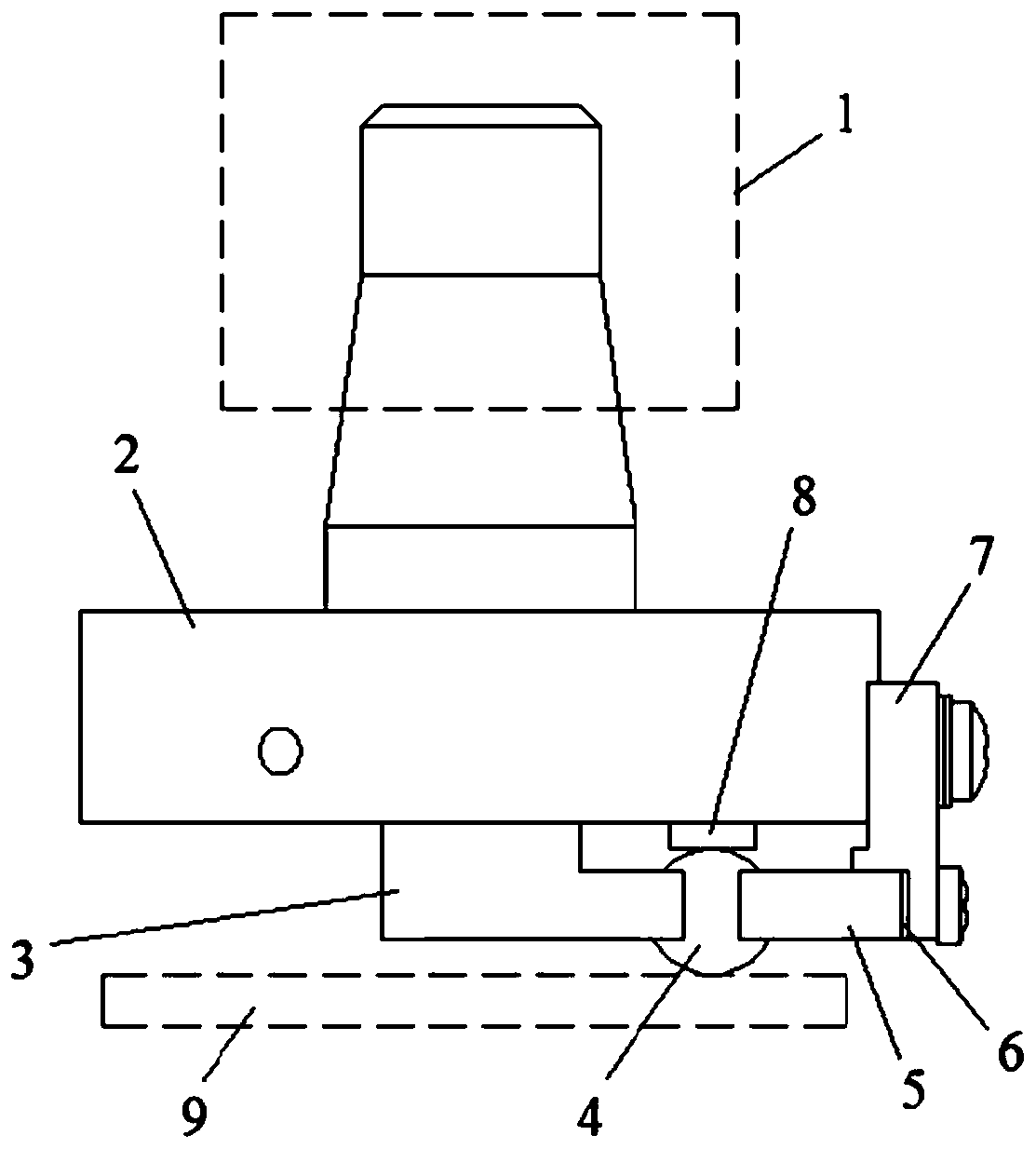

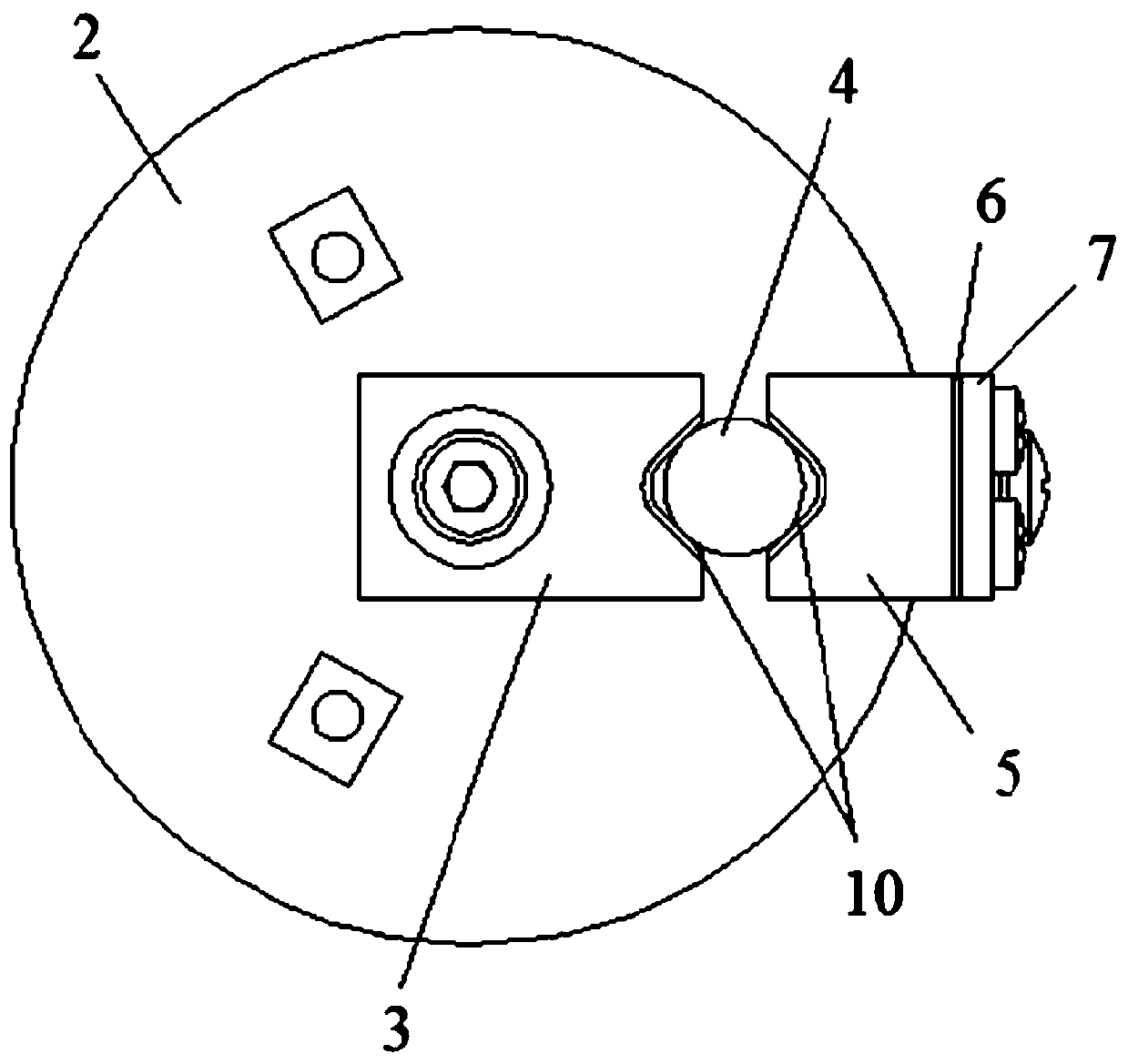

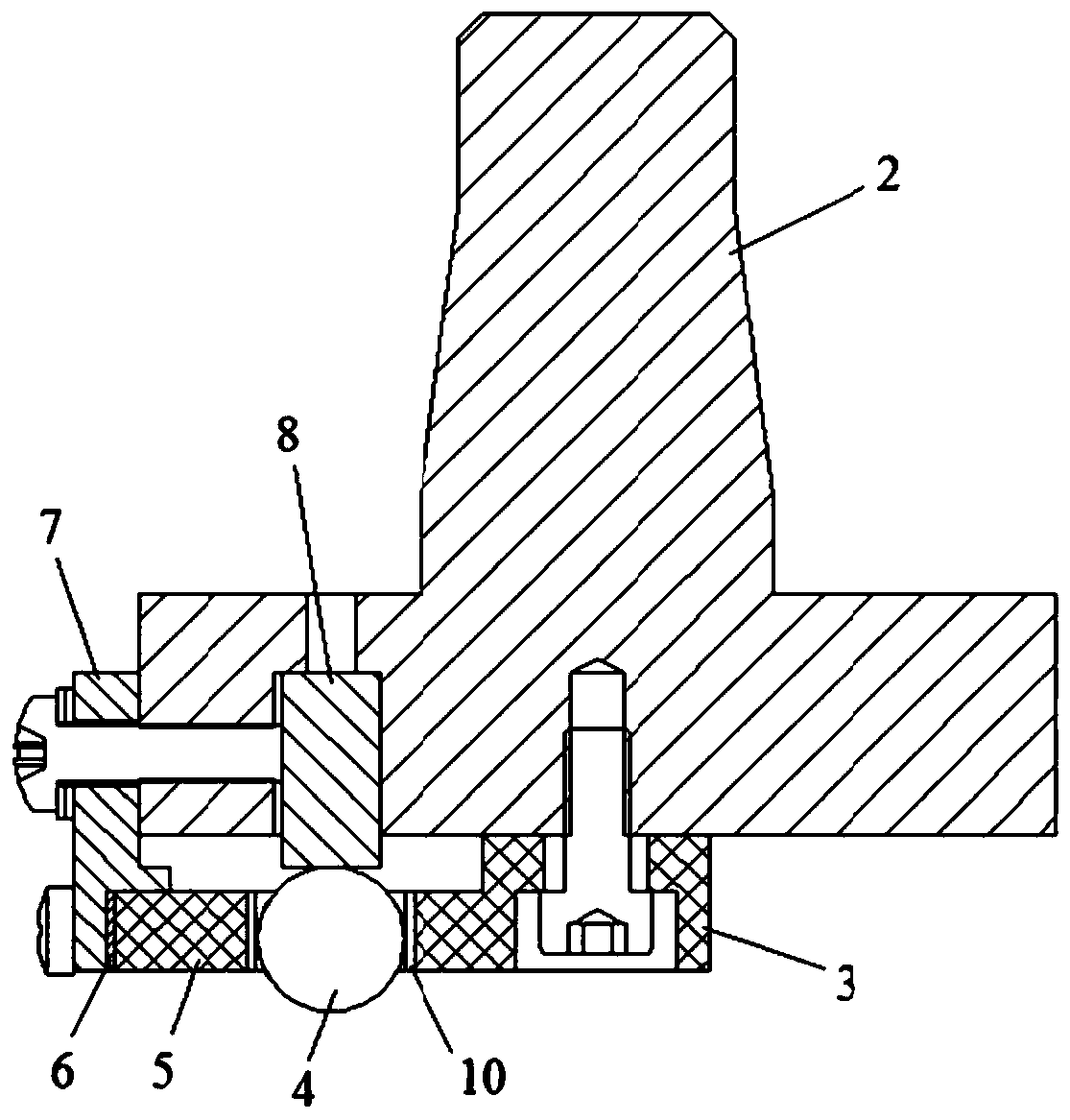

[0034] see figure 1 , the present invention provides a pairing device for ceramic ball rolling friction test, including a mounting chuck 2, the mounting chuck 2 is connected to the spindle system 1 of the friction testing machine, and at the same time, the mounting chuck 2 It includes a connecting part and a supporting part, wherein the supporting part is arranged below the connecting part.

[0035] The connecting part adopts a conical structure, which can be automatically aligned with the spindle system 1, and the connection is reliable and high in precision. The spindle system 1 drives the mounting chuck 2 to rotate.

[0036] The holding part is a cylindrical structure, and a left holder 3 is installed at the lower center of the cylindrical structure. The other end of the left cage 3 is provided with a first V-shaped groove.

[0037] A connecting frame 7 is inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com