Line structured light-based cast workpiece surface quality detection method and system thereof

A quality inspection method and technology on the surface of workpieces, applied in the direction of optical testing of flaws/defects, measuring devices, and material analysis through optical means, can solve problems such as incomplete inspection, inability to quantify, and low efficiency of manual inspection, and achieve overcoming efficiency low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

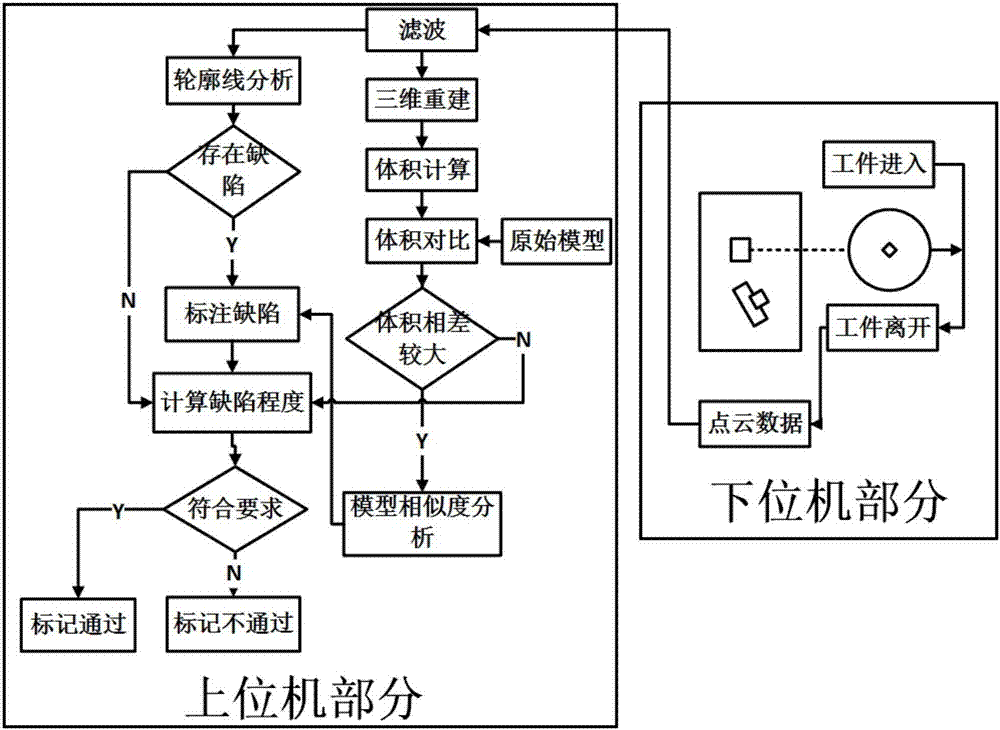

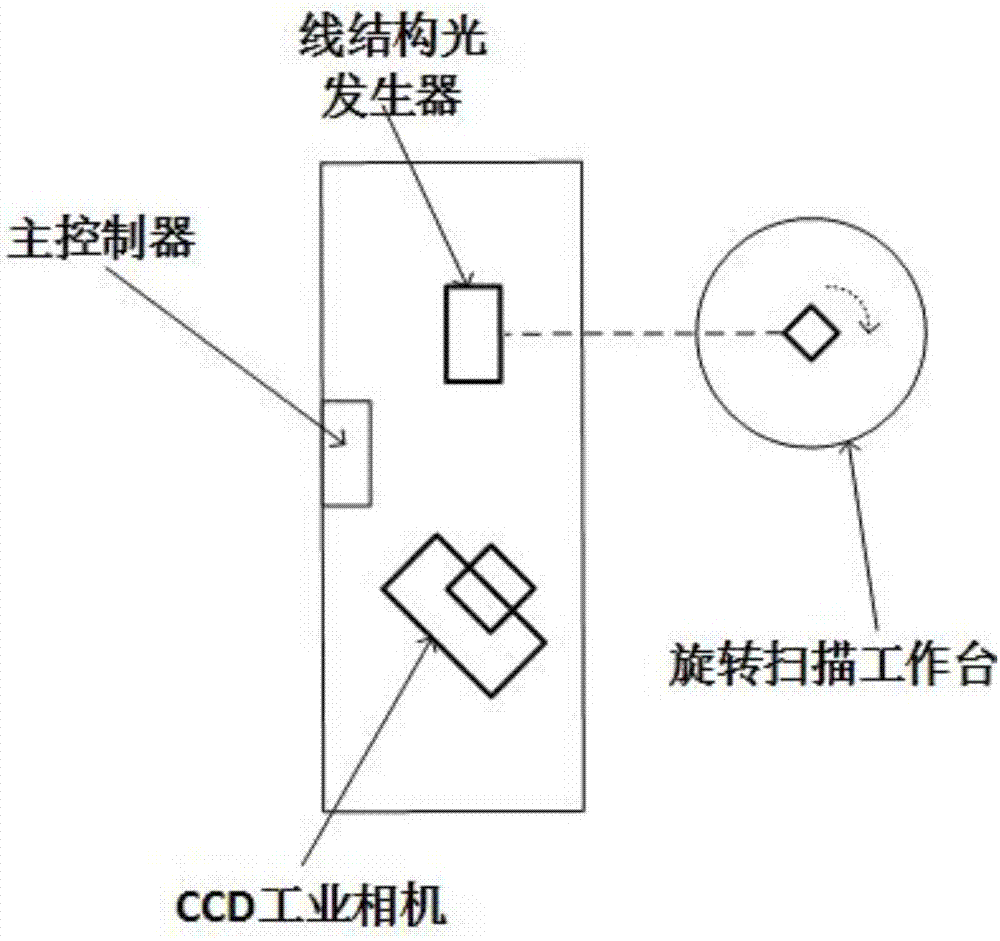

[0026] The method for detecting the surface quality of casting workpieces based on the line structured light of the present invention is mainly divided into two parts: the detection part of the lower computer and the analysis and comparison parts of the upper computer. The overall workflow is as figure 1 , Including the following steps:

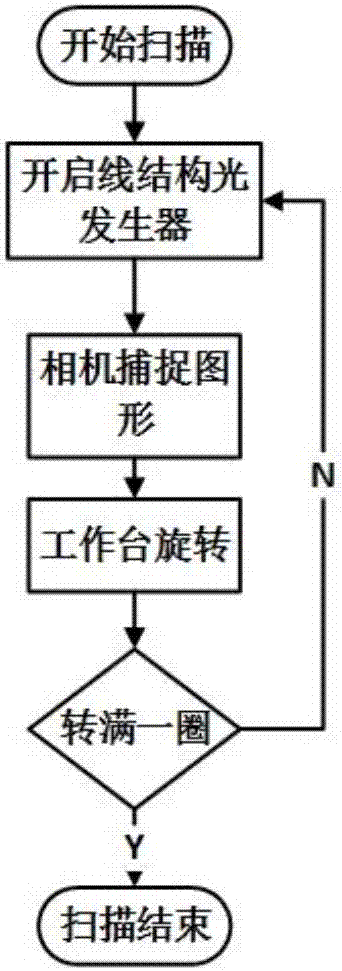

[0027] 1) The workpiece enters the rotating scanning table from the conveyor belt, and the workpiece returns to the conveyor belt to leave after one revolution on the table;

[0028] 2) The lower computer sends the 3D point cloud data obtained in step 1) to the upper computer, and the upper computer filters the point cloud data to remove high-frequency noise;

[0029] 3) The filtered data is processed at the same time in two analysis methods: surface contour analysis and 3D model similarity analysis; two methods are used to find out the problematic parts of the workpiece and choose to mark defects or directly calculate the degree of defects;

[0030]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com