Bionic gas flow rate sensor of hair seam combination

A gas flow rate and sensor technology, applied in the direction of fluid velocity measurement, instrumentation, velocity/acceleration/impact measurement, etc., can solve the problems of being affected by temperature, expensive, and low precision of mechanical detection, and achieve good economy, simple structure, Ease of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

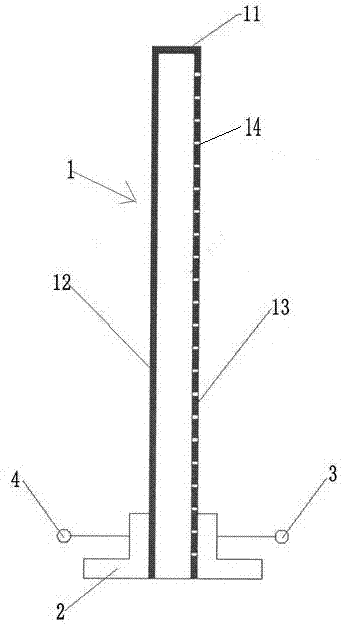

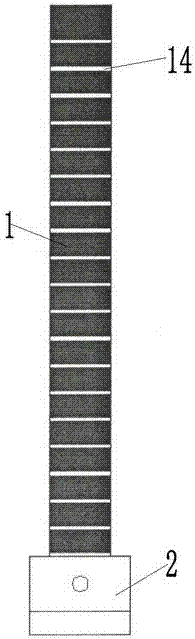

[0014] Such as figure 1 with figure 2 As shown, this embodiment is composed of a caulking rod 1, a fixed base 2, a first electrode lead 3 and a second electrode lead 4, and the caulking rod 1 is assembled with the fixed base 2 to form a cantilever beam structure; The side 12 leads out the first electrode lead 3, and the right side 13 points out the second electrode lead 4, the first electrode lead 3 and the second electrode lead 4 are all fixed on the fixed base 2, wherein the caulking hair rod 1 is insulated by elastic The upper surface 11, the left side 12 and the right side 13 of the caulking hair shaft 1 are all coated with a conductive material layer, and the conductive material layer on the right side 13 is processed with micro-nano slits 14 in the horizontal direction.

[0015] Working process and principle of the present invention:

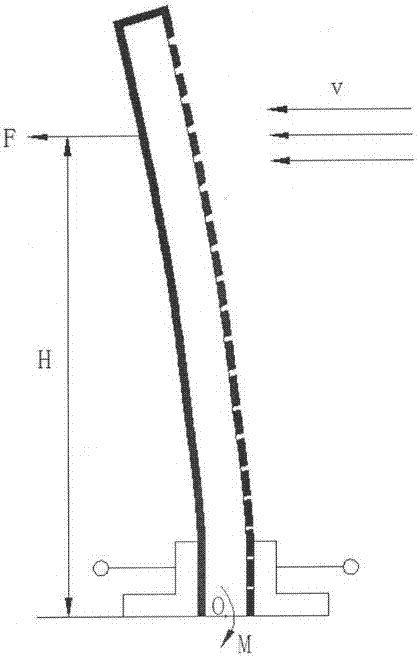

[0016] Such as image 3 As shown, when the airflow with a velocity of V is tested, the force F exerted by the airflow on the caulking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com