Electromechanical system control method and device

A technology of electromechanical systems and control methods, applied in computer control, program control, comprehensive factory control, etc., can solve the problems of complex design and high load of electromechanical system control software, and achieve the goal of reducing the use of queries, reducing loads, and reducing complexity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

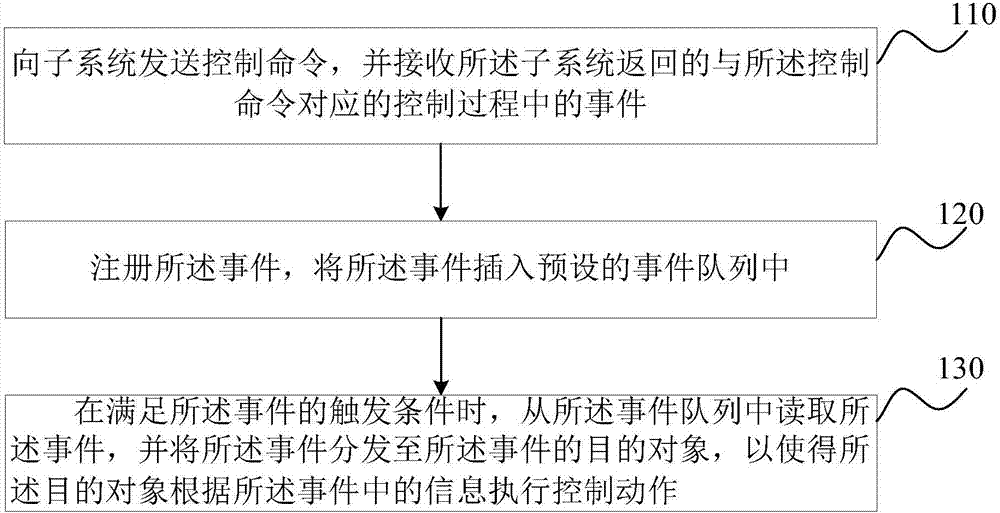

[0037] figure 1 It is a schematic flowchart of a method for controlling an electromechanical system provided in Embodiment 1 of the present invention, and the method in this embodiment is applicable to the case of controlling an electromechanical system. It can be executed by the control device of the electromechanical system, which can be realized by means of hardware and / or software, and can generally be applied to the main system of the electromechanical system.

[0038] see figure 1 , the electromechanical system control method, comprising:

[0039] S110. Send a control command to the subsystem, and receive an event in the control process corresponding to the control command returned by the subsystem.

[0040] In the electromechanical system, the upper computer directly facing the user is called the main system, and the subsystem can be a specific component for executing various operation commands. An electromechanical system consists of at least one subsystem, usually ...

Embodiment 2

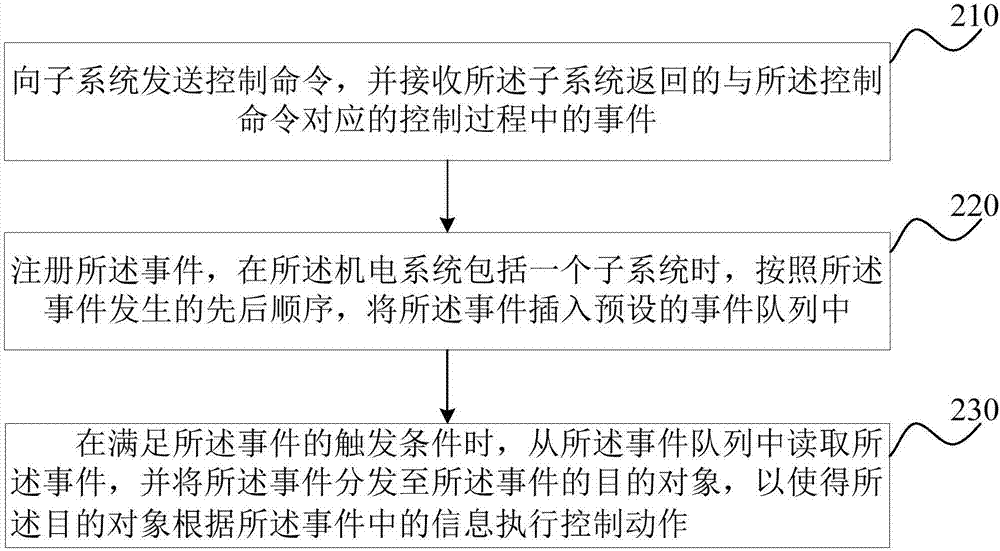

[0052] figure 2 It is a schematic flowchart of the electromechanical system control method provided by Embodiment 2 of the present invention. This embodiment is optimized on the basis of the above-mentioned embodiments, and the event is inserted into the preset event queue. The specific optimization is as follows: when the electromechanical system includes a subsystem, according to the order of the events, the Events are inserted into the preset event queue.

[0053] see figure 2 , the electromechanical system control method, comprising:

[0054] S210. Send a control command to the subsystem, and receive an event in the control process corresponding to the control command returned by the subsystem.

[0055] S220. Register the event. When the electromechanical system includes a subsystem, insert the event into a preset event queue according to the sequence in which the events occur.

[0056] If the electromechanical system includes only one subsystem, then for this subsys...

Embodiment 3

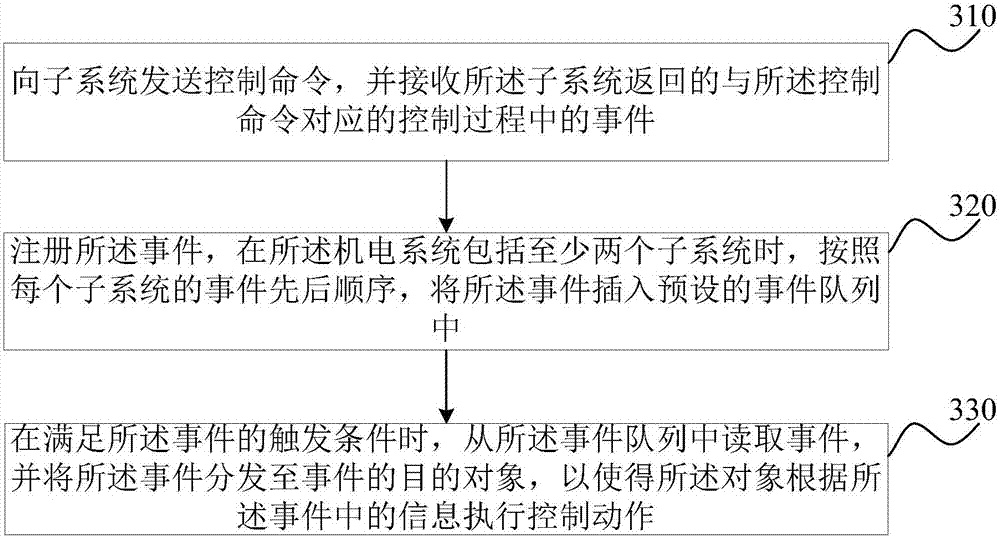

[0060] image 3 It is a schematic flowchart of the electromechanical system control method provided by Embodiment 3 of the present invention. This embodiment is optimized on the basis of the above-mentioned embodiments, and the event is inserted into the preset event queue. The specific optimization is: when the electromechanical system includes at least two subsystems, according to the sequence of events of each subsystem, insert The event is inserted into a preset event queue.

[0061] see image 3 , the electromechanical system control method, comprising:

[0062] S310. Send a control command to the subsystem, and receive an event in the control process corresponding to the control command returned by the subsystem.

[0063] S320. Register the event. When the electromechanical system includes at least two subsystems, insert the event into a preset event queue according to the sequence of events of each subsystem.

[0064] An electromechanical system usually includes at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com