Acquisition system of maintenance reliability data of numerically controlled machine tool and method

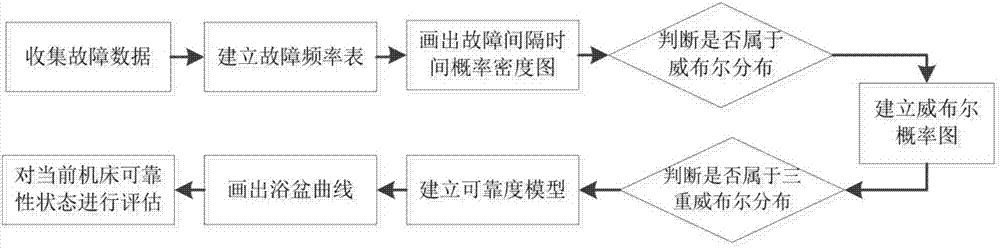

A technology of data acquisition system and numerical control machine tool, applied in general control system, control/regulation system, program control and other directions, can solve the problems of high randomness, increase the cost of data acquisition, reduce the accuracy of reliability data, etc., to improve the use of Longevity and reliability, improved diagnostic accuracy, and the effect of facilitating statistics and analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

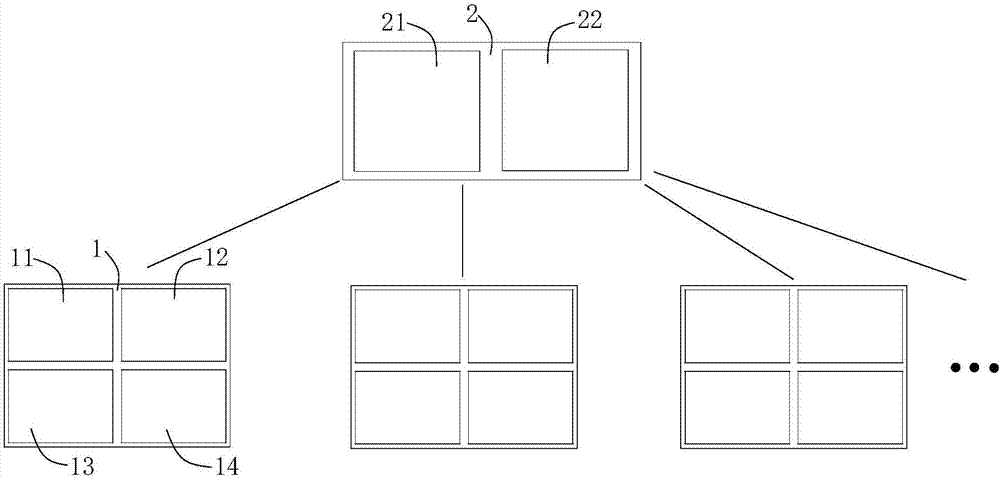

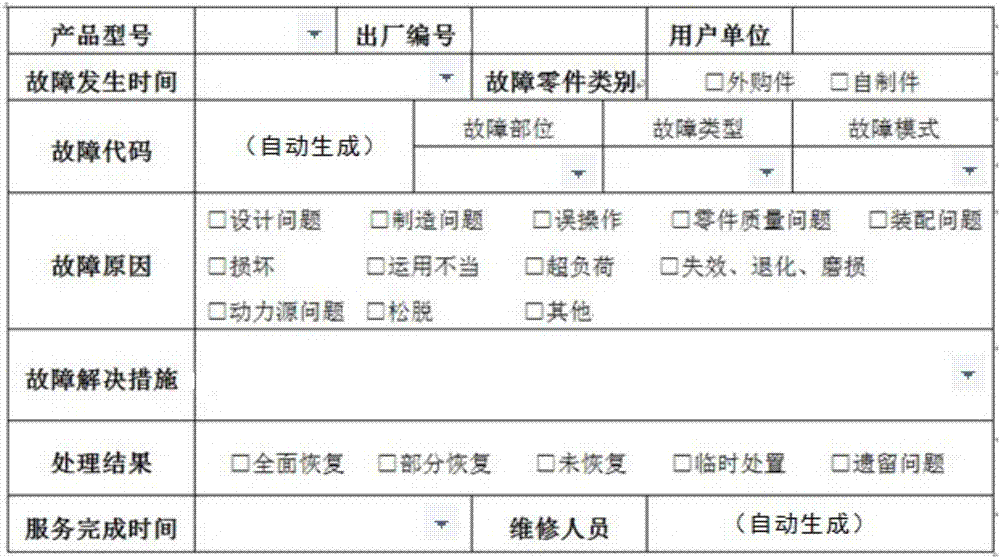

[0063] Embodiment: during concrete implementation, described mobile terminal is mobile phone or panel computer, by installing corresponding APP on mobile phone or tablet computer, this APP realizes the one-way transmission of data through the network mode of WIFI / 2G / 3G / 4G, in It can be automatically saved in an environment without a network, and the data upload will be automatically completed in an environment with a network. Maintenance personnel need to log in to the APP account to complete the entry of maintenance reliability data, and the APP can only transmit reliability data to the database server, and cannot read or modify data in the database and other operations, but the account is reserved for uploading Record. The information entered mainly includes the user unit, product model, factory serial number, faulty part category, fault occurrence time, fault code, fault cause, fault resolution measures, processing results, maintenance personnel and service completion time,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com