An integrated segmented internal and external zigzag special-shaped cross-section solenoid magnetic field structure

A special-shaped cross-section, solenoid technology, applied in the direction of the circuit components of the transit time type electronic tube, etc., to achieve the effects of high field strength, convenient assembly and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] All features disclosed in this specification, or steps in all methods or processes disclosed, may be combined in any manner, except for mutually exclusive features and / or steps.

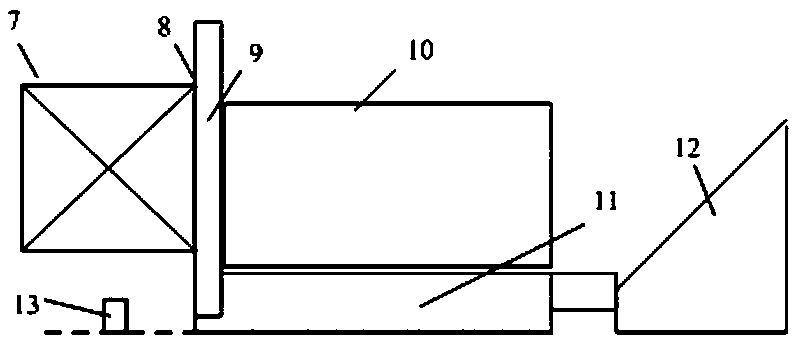

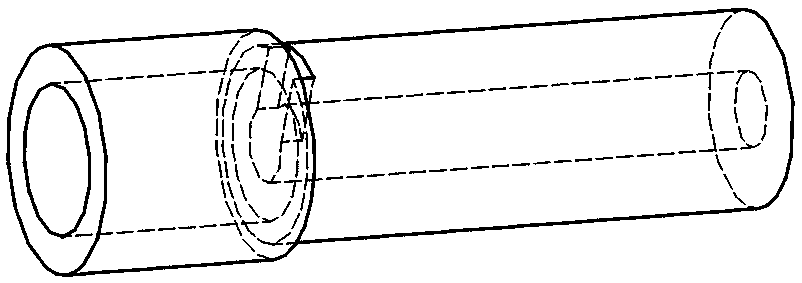

[0031] Such as image 3 , the overall shape structure of the solenoid of the present invention includes an integrated segmented solenoid skeleton, and the integrated segmented solenoid skeleton includes a segmented front solenoid and a segmented rear solenoid, and the There is an insertion waveguide groove at the section between the segmented front solenoid and the segmented rear solenoid, which is the position where the half-slot is fed into the waveguide, and the size is just coordinated with the introduction waveguide of the microwave seed source.

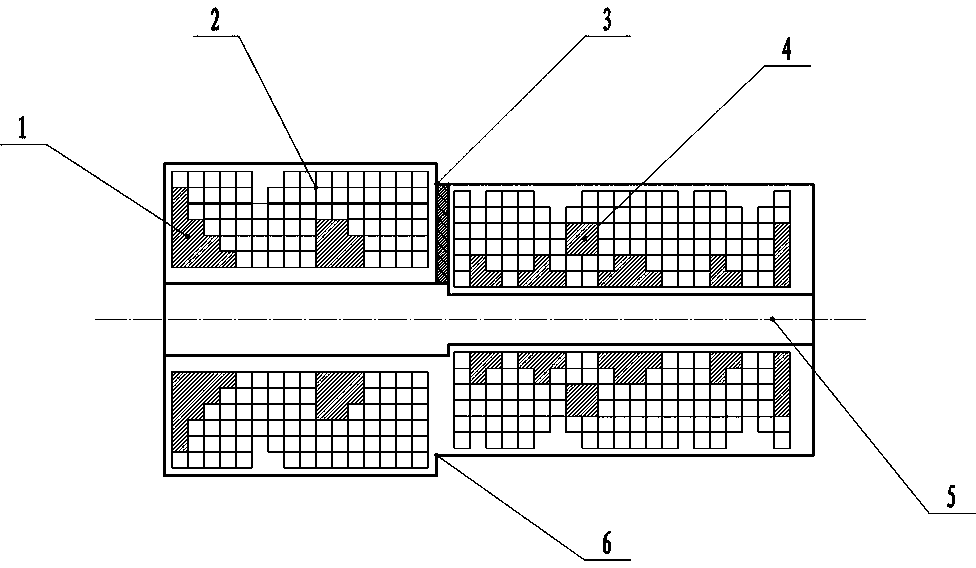

[0032] One of the key points of the present invention is to divide the traditional wire wrapping into a grid, and then perform wiring; grid the winding area, find all the cross-sectional areas that need to be wound, and design according to the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com