Energy storage and conversion system based on solid oxide cells

A solid oxide, energy storage technology, applied in the electrolyte treatment of solid electrolyte batteries, solid electrolyte fuel cells, fuel cells, etc., can solve problems such as fuel cell failure and damage, inability to completely seal the fuel, and failure of SOFC to operate normally.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is explained in further detail below in the form of examples, but the present invention is not limited to the examples.

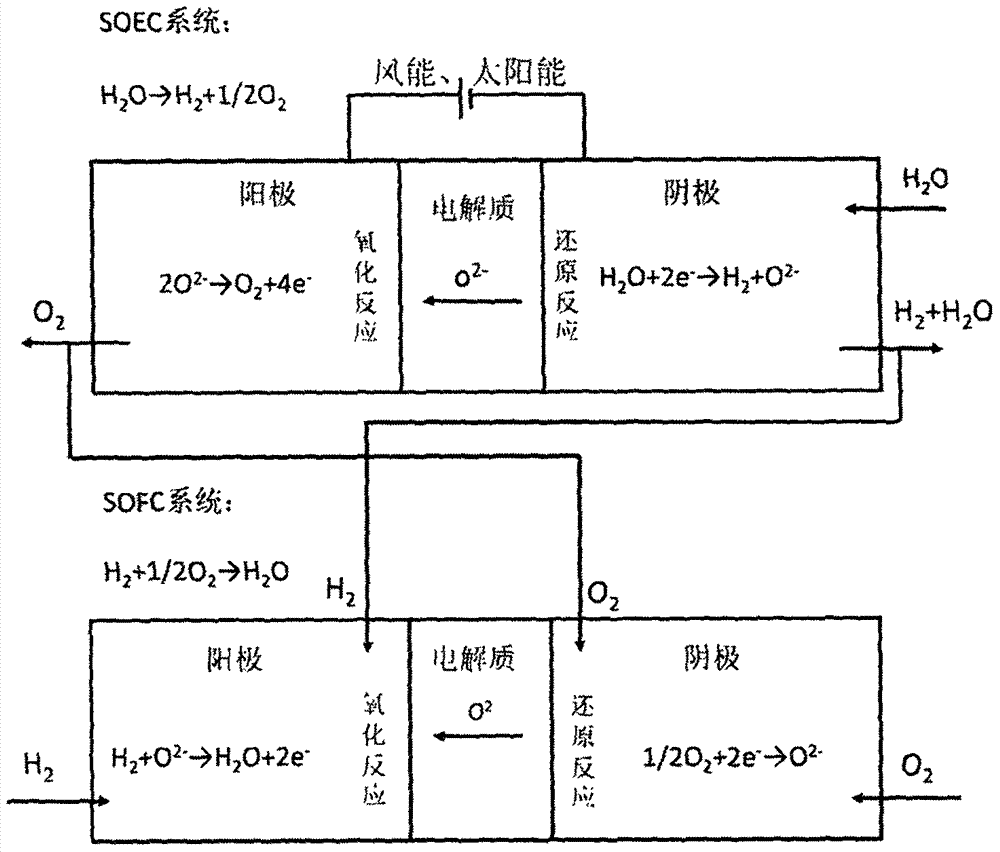

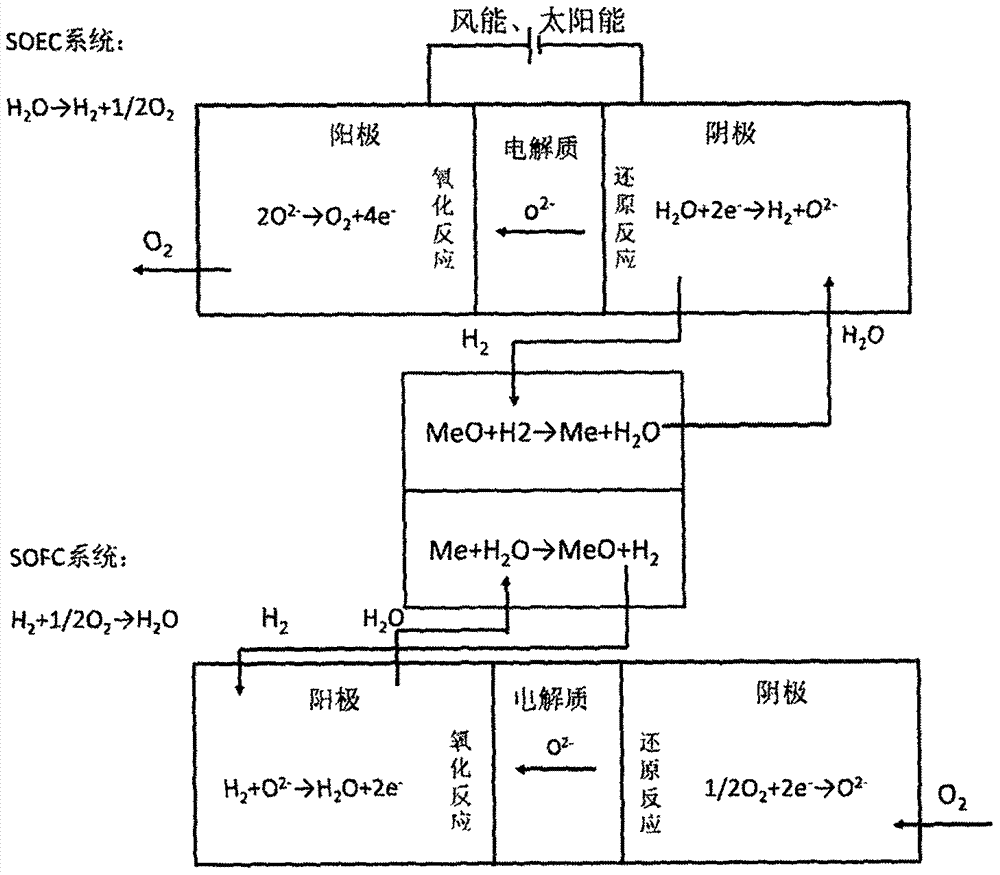

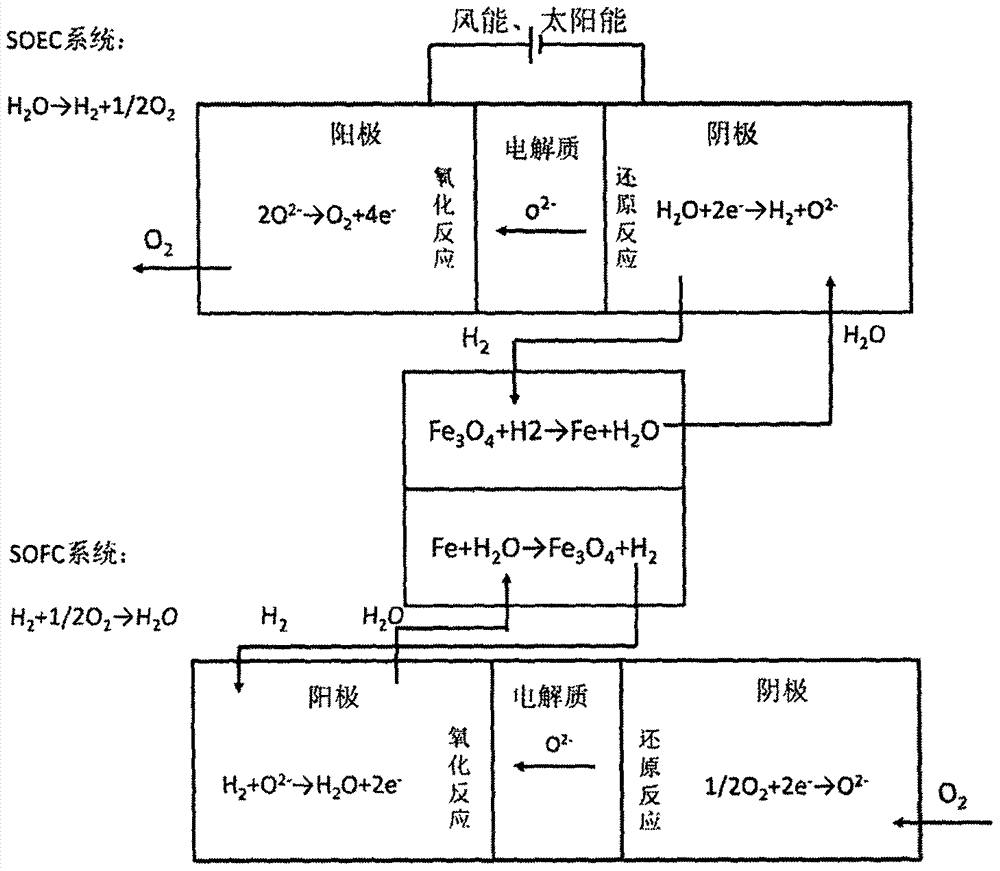

[0015] A solid oxide cell (SOC) system consisting of a solid oxide fuel cell (SOFC) and a solid oxide electrolytic cell (SOEC).

[0016] SOFC working mode:

[0017] Oxygen in the air on the cathode side is reduced to oxygen ions by the electrolyte.

[0018] 1 / 2O 2 +2e - →O 2- (1)

[0019] A slight excess of hydrogen gas is introduced into the anode, sealed, oxygen ions enter the anode through the electrolyte, combine with hydrogen to form water, and release electrons to the external circuit to achieve the purpose of power generation.

[0020] h 2 +O 2- →H 2 O+2e - (2)

[0021] The overall response is:

[0022] h 2 +1 / 2O 2 →H 2 O (3)

[0023] Since the iron powder has not completely reacted, the generated water will continue to react with the iron powder under certain conditions to form iron oxide and release hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com