Bipolar lead-acid storage battery

A lead-acid battery, bipolar technology, applied in the field of batteries, can solve the problems of electrolyte crossover in compartments, self-discharge, micro-short circuit, etc., to avoid water loss, improve service life, and increase specific energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

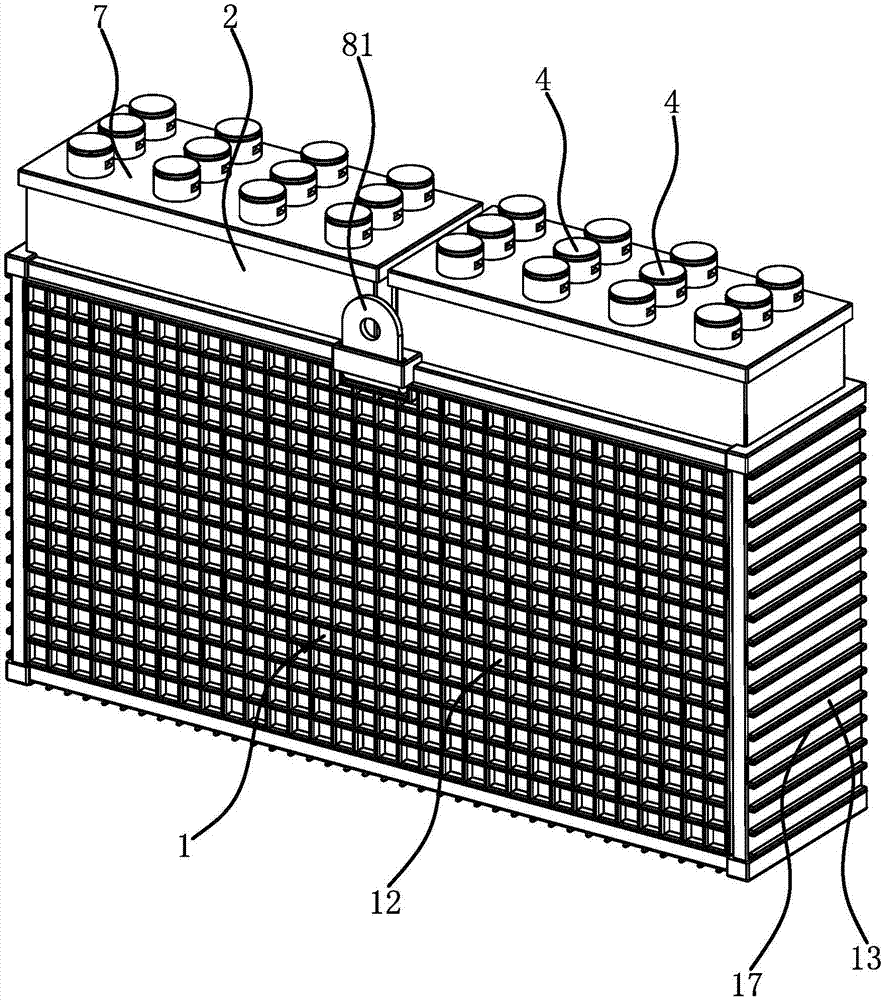

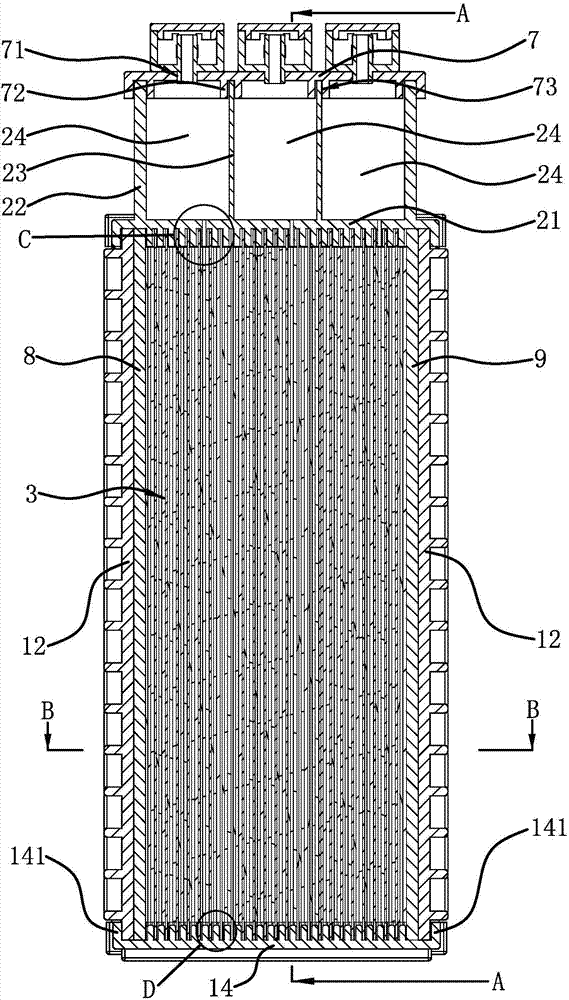

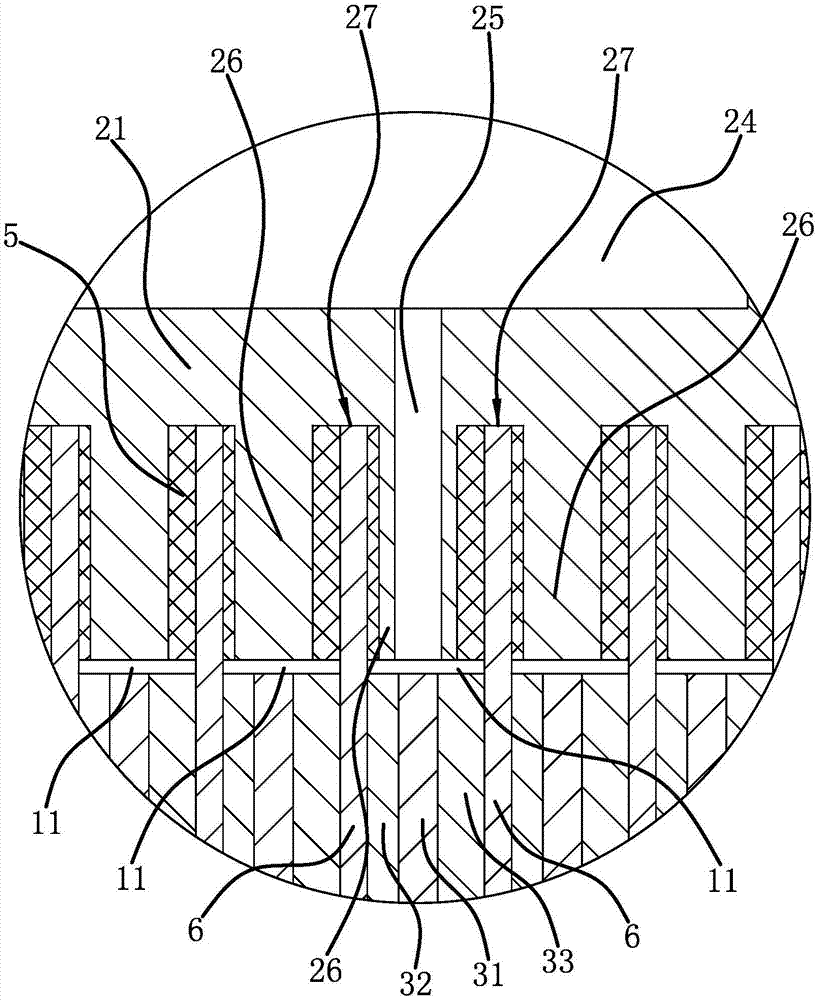

[0036] Such as figure 1 As shown, a bipolar lead-acid battery includes a casing 1 and a top cover 2 , the casing 1 is rectangular and has an upper opening, and reinforcing ribs 17 are evenly distributed on the outer wall of the casing 1 . Such as figure 2 , image 3 As shown, a plurality of bipolar plates 6 are fixedly connected in the housing 1, and the plurality of bipolar plates 6 are arranged in parallel, and the inner cavity of the housing 1 is divided into several independent sealed compartments 11 by the plurality of bipolar plates 6. 11 is flat, and several compartments 11 are arranged in sequence along the width direction of the casing 1, and a battery cell 3 is fixedly arranged in each compartment 11, and each battery cell 3 includes a separator 31, a negative electrode plate 32 and The positive plate 33 and the negative plate 32 are located on one side of the separator 31, and the positive plate 33 is located on the other side of the separator 31. The separator 3...

Embodiment 2

[0040] The structure of this bipolar lead-acid battery is basically the same as that of Embodiment 1, the difference is that the top cover 2 includes several air chamber cavities 22, and each air chamber cavity 22 is located above the cover plate 21 and is independent of each other. The inner cavity of the cavity 22 is an air chamber 24, and several air chamber cavities 22 and cover plate 21 are integrally structured to ensure the airtightness of the air chamber 24. Of course, the top cover 2 can also be designed into several lengths in the actual processing process. Strip-shaped air chamber cavity 22, the inner cavity of the air chamber cavity 22 is divided into several air chambers 24 along the length direction, that is, an exhaust chamber 24 is formed in each air chamber cavity 22, which can also ensure that the air chamber 24 of tightness.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com