Pollinator capable of improving pollination rate of pear tree

A technology of pollination rate and pollinator, applied in the direction of application, organic fertilizer, nitrogen fertilizer, etc., can solve the problems of high production cost, large manpower and material resources, and large labor load, and achieve the goal of increasing pollination rate, increasing success rate, and reducing labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

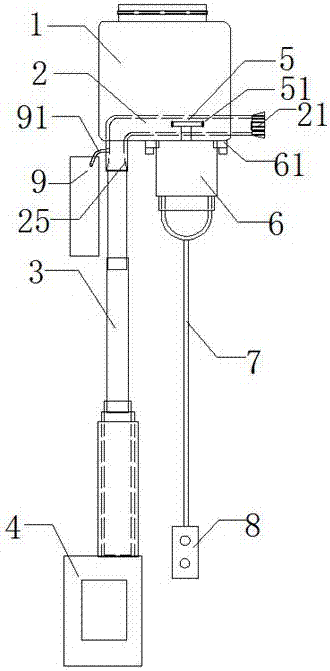

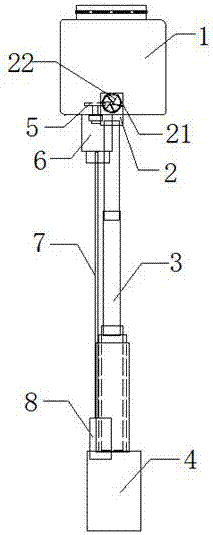

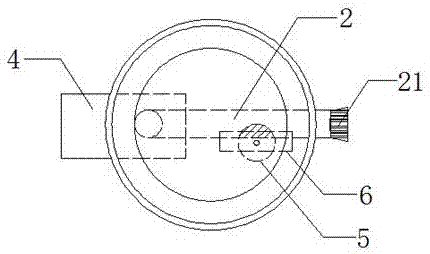

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

[0017] Such as Figure 1-3 As shown in , a pollinator for improving the pollination rate of pear trees comprises a powder storage tank 1, and the powder storage tank 1 is provided with an L-shaped tube 2 that runs through the bottom surface and the side of the powder storage tank 1, and the bottom of the L-shaped tube 2 is connected to a flexible The multi-section airflow lifting rod 3, the electric blower 4 is connected to the bottom of the airflow lifting rod 3, the pipe diameter of the vertical part of the L-shaped pipe 2 gradually decreases from bottom to top, and a through hole is provided on the middle side wall of this section of pipeline 25 , the through hole communicates with the liquid storage bag 9 through the flexible pipe 91, and the auxiliary liquid is installed in the liquid storage bag 9; the auxiliary liquid is configured by the following raw materials...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com