Bulrush board weaving equipment and weaving method thereof

A technology of rush boards and equipment, which is applied in mechanical equipment, sugarcane machining, etc., can solve problems such as complex processing procedures, and achieve the effects of uniform distribution, low maintenance costs, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

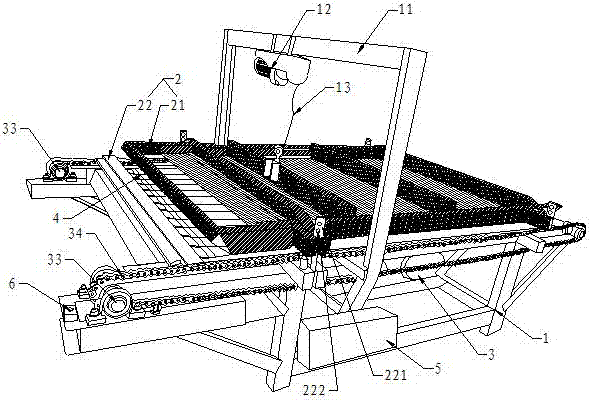

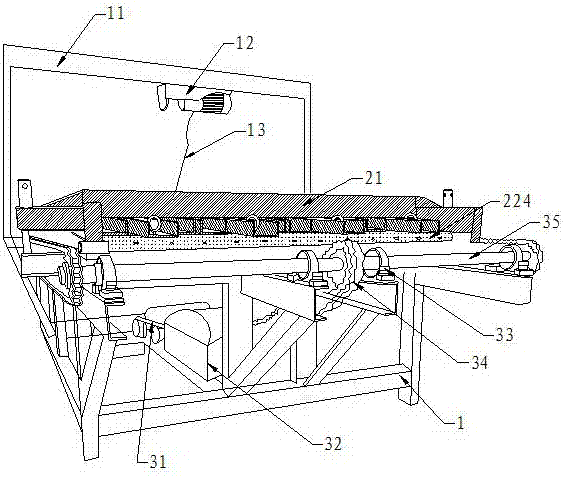

[0032] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-8 As shown, in this embodiment, a rush board weaving equipment includes a frame (1), a clamping part (2), and a transmission part (3). The upper part of the frame (1) is provided with a clamping part (2) , the bottom is provided with a transmission part (3);

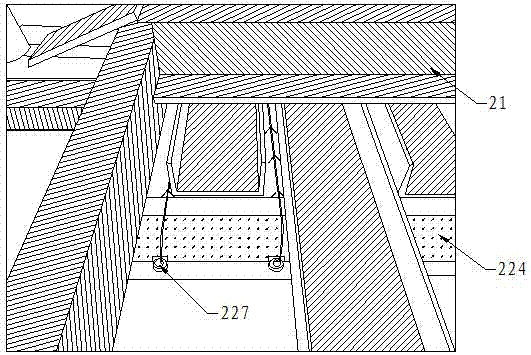

[0033] The clamping part (2) is composed of an upper clamping plate (21) and a lower clamping plate (22). The four corners of the lower clamping plate (22) are provided with circular holes matching the four corners of the upper clamping plate (21). Fixing bar (221), upper clamping plate (21) can be hoisted by electric hoist (12) and lifting rope (13) on the frame (1) beam (11), upper clamping plate (21) and The height between the lower clamping plates (22) is 5-10CM, this height is installed through the circular height adjustment hole (222) on the fixed rod (221) and the adjustment screw rod (223) installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com