Magnetic conduction block and press machine for manufacturing magnetic conduction block

A technology of magnetic conductive blocks and presses, applied in the directions of presses, punching machines, manufacturing tools, etc., can solve the problems of low service life and magnetic conductive effect of magnetic conductive blocks, low processing quality and processing efficiency, and easy vibration of workpieces. Achieve the effect of improving the magnetic conductivity, simple structure, easy to manufacture and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

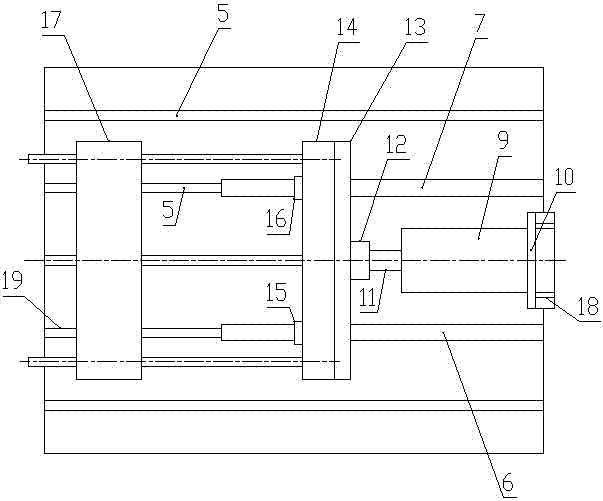

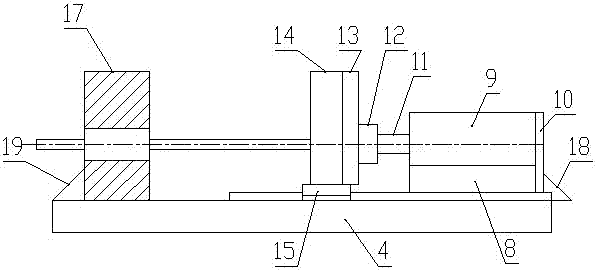

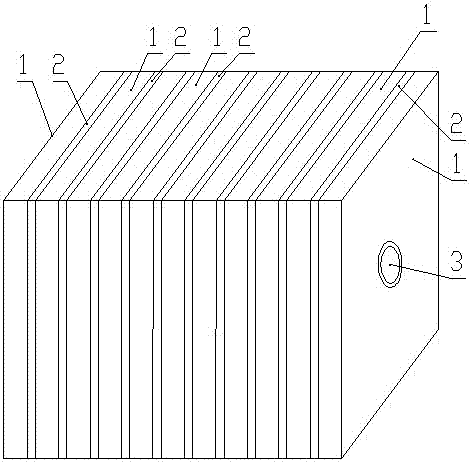

[0019] Such as figure 1 , figure 2 and image 3 As shown, the magnetic block of the present invention includes alternately arranged permalloy plates 1 and nickel-bronze alloy plates 2; in the direction from one end of the magnetic block to the other end, the permalloy plates 1 are in odd positions, and the nickel-bronze alloy plates 2 is located in an even number, and the number of permalloy plates 1 is one more than that of nickel-bronze alloy plates 2; adjacent permalloy plates 1 and nickel-bronze alloy plates 2 are bonded and pressed together by a metal adhesive. The center of each permalloy plate 1 and nickel bronze alloy plate 2 is provided with a central through hole 3 , and the central through holes 3 of each permalloy plate 1 and nickel bronze alloy plate 2 communicate with each other.

[0020] The permalloy plates 1 are provided with 11 pieces, and the nickel-bronze alloy plates 2 are provided with 10 pieces; the metal adhesive is an epoxy resin adhesive.

[0021]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com