Boxing robot of bulk product

A technology of robot and robot body, applied in the direction of packaging, transportation and packaging, single objects, etc., can solve the problems of single purpose, complex structure, low intelligence, etc., to improve accuracy and stability, save labor costs, improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

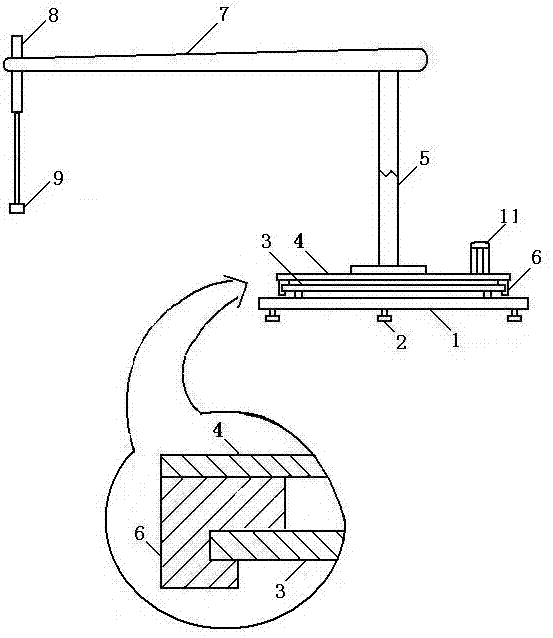

Method used

Image

Examples

Embodiment 1

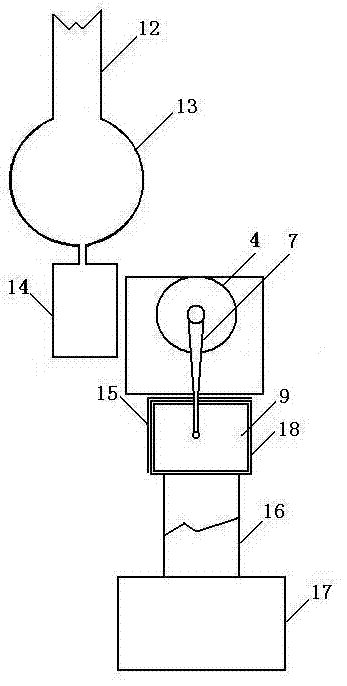

[0020] Embodiment 1: After unfolding the back cover of the carton 18 manually, it is fitted to the carton positioning frame 15, and the packing robot is started. When the object to be packed is food or architectural ceramics with quantitative independent packaging, etc. and is output by the output conveyor belt of the automatic production line, it is accepted by the connecting groove 12 and input to the buffer groove 13, because the buffer groove 13 is set at an angle, and enters the buffer groove 13 The packaged objects directly enter the integration tank 14. During the process of entering the integration tank 14, due to the quantitative and fixed-angle rotation distribution of the buffer tank 13, after being quantitatively distributed between the two partitions and arranged, the length and width parameters It matches with carton 18 and gripper 9.

Embodiment 2

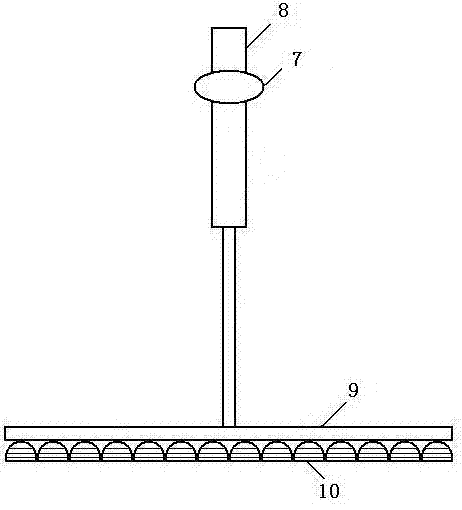

[0021] Embodiment 2: The default position of the gripper 9 is above the integration groove 14 when it is in standby state. When the packaged object is full in the integration tank 14, the control computer instructs the lifting cylinder 8 to descend, and the handle 9 below it falls to the packaged object in the integration tank 14, and then instructs the pneumatic suction cup 10 to absorb the rear gripper 9 of the packaged object. Rising to the set position, the control computer instructs the servo motor 11 to rotate according to the preset rotation angle of the rotating disk 4, and the gripper 9 is brought to the top of the carton 18 by the rotating disk 4 through the column 5 and the arm body 7. At this time, the control computer instructs the lifting cylinder 8 to lower the handle 9 to the set height inside the carton 18, and then instructs the pneumatic suction cup 10 to release the adsorption of the packaged objects, and the packaged objects are loaded into the first layer ...

Embodiment 3

[0022] Embodiment 3: The descending depth of the gripper 9 inside the carton 18 is based on the thickness of the packaged object, and the parameters that decrease layer by layer are input on the control panel in advance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com