Cellular biogas fermentation device

A technology of biogas fermentation and honeycomb type, which is applied in the field of biogas fermentation equipment and honeycomb biogas fermentation equipment, can solve the problems of poor temperature control effect and uneven heating of raw materials, achieve optimal mixing effect, overcome uneven heating, and accelerate exhaust speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

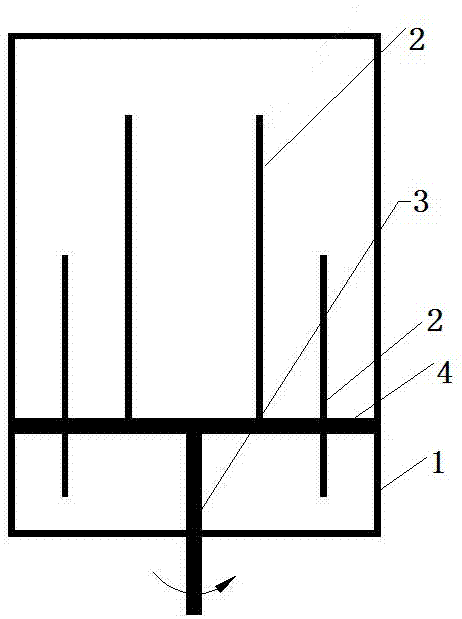

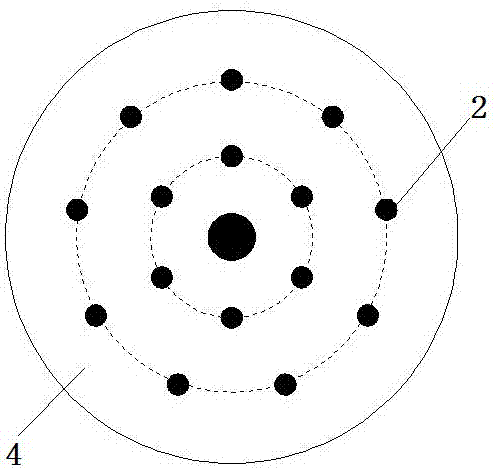

[0023] A honeycomb biogas fermentation device, comprising a fermenter 1, a rotating mechanism, a driving mechanism and a temperature-controlled heating rod 2, the rotating mechanism is arranged in the fermenter 1, the driving mechanism is connected to the rotating mechanism to drive the rotating mechanism to move, and the temperature-controlled heating rod 2 There are multiple temperature-controlled heating rods 2 arranged along the axial direction of the fermenter 1, and the temperature-controlled heating rods 2 are evenly distributed on the rotating mechanism; when the rotating mechanism rotates, the temperature-controlled heating rods 2 form stirring blades.

[0024] In this embodiment, the driving mechanism includes a motor and a transmission connected to the motor. The rotating mechanism includes a rotating shaft 3 and a turntable 4. One end of the rotating shaft 3 is fixedly connected to the turntable 4, and the other end is connected to the transmission outside the fermen...

Embodiment 2

[0028] A honeycomb biogas fermentation device, comprising a fermenter 1, a rotating mechanism, a driving mechanism and a temperature-controlled heating rod 2, the rotating mechanism is arranged in the fermenter 1, the driving mechanism is connected to the rotating mechanism to drive the rotating mechanism to move, and the temperature-controlled heating rod 2 There are multiple temperature-controlled heating rods 2 arranged along the axial direction of the fermenter 1, and the temperature-controlled heating rods 2 are evenly distributed on the rotating mechanism; when the rotating mechanism rotates, the temperature-controlled heating rods 2 form stirring blades.

[0029] In this embodiment, the driving mechanism includes a motor and a transmission connected to the motor. The rotating mechanism includes a rotating shaft 3 and a turntable 4. One end of the rotating shaft 3 is fixedly connected to the turntable 4, and the other end is connected to the transmission outside the fermen...

Embodiment 3

[0036] A honeycomb biogas fermentation device, comprising a fermenter 1, a rotating mechanism, a driving mechanism and a temperature-controlled heating rod 2, the rotating mechanism is arranged in the fermenter 1, the driving mechanism is connected to the rotating mechanism to drive the rotating mechanism to move, and the temperature-controlled heating rod 2 There are multiple temperature-controlled heating rods 2 arranged along the axial direction of the fermenter 1, and the temperature-controlled heating rods 2 are evenly distributed on the rotating mechanism; when the rotating mechanism rotates, the temperature-controlled heating rods 2 form stirring blades.

[0037] In this embodiment, the driving mechanism includes a motor and a transmission connected to the motor. The rotating mechanism includes a rotating shaft 3 and a turntable 4. One end of the rotating shaft 3 is fixedly connected to the turntable 4, and the other end is connected to the transmission outside the fermen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com