Internally Cooled High Compression Lean-Burning Internal Combustion Engine

A technology of hydrocarbon fuels, internal combustion engines, applied in the direction of engine operation, internal combustion piston engines, adding non-fuel substances to fuel, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0261] Picture 10 A graph showing the efficiency of the engine operating under various engine loads, including water injection and charge air injection pressure. Work efficiency is calculated based on the input of air / fuel and injected water as described herein. The test engine was an improved Yanmar L 100 single-cylinder diesel engine, which was coupled to a 5KW generator with a cylinder diameter of 86mm×75mm×stroke, a displacement of 435cc, and an engine compression ratio of 19:1. The engine is improved with removable plates that block airflow to facilitate research on internal cooling. Additional holes are drilled in various locations for water injectors (e.g. through commercially available fuel injectors suitable for injecting water at 80 psi) and pressure and temperature instruments. Inject air with the supercharger at the indicated pressures (e.g., 5 PSI (pounds per square inch), 10 PSI, and 15 PSI). At 300° before TDC, water injection was performed by port injection a...

example 2

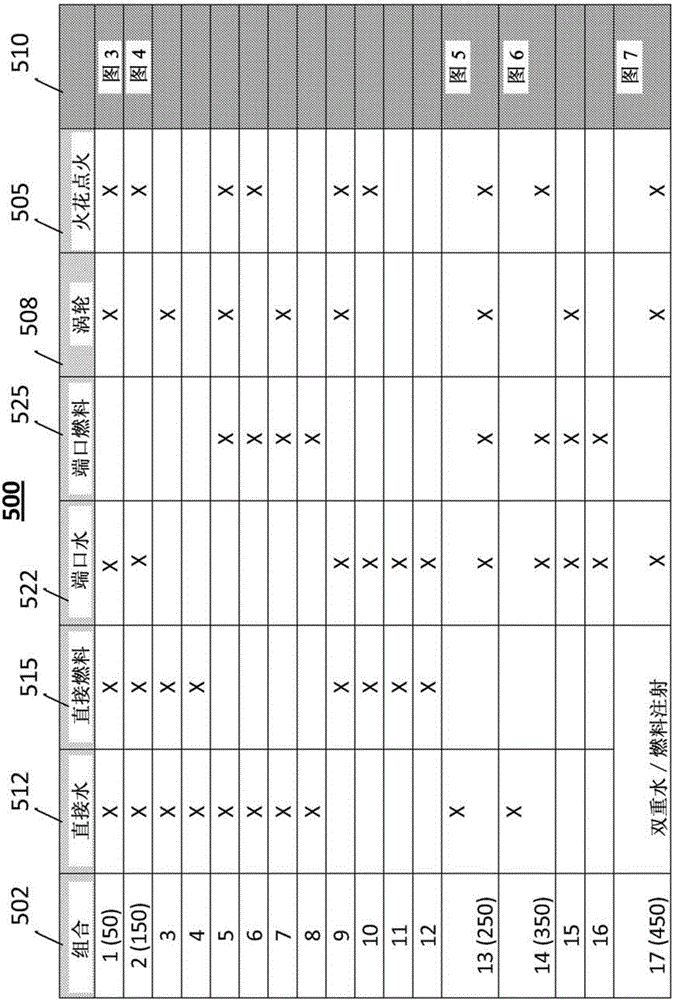

[0270] Picture 11 Table 2 and Table 2 show the electrical efficiency of the engine under various engine loads and 10PSI supercharged air injection pressure, and compare the water injection internal cooling with the absence of water injection and air cooling. At 300° before TDC, water was injected at 80 psi for 3 ms. The engine speed is 6000RPM. The data in Table 2 shows that under 10 psi air injection, the use of water injection internal cooling can greatly increase efficiency. Under a 4KW engine load, the efficiency increases from 32% to 46%. Table 2 shows Picture 11 Basic data shown as well as water / fuel ratio and lambda (air-fuel ratio).

[0271] Table 2 In the presence and absence of water injection ( Picture 11 ) Test data of the engine under various loads and constant air pressure

[0272]

[0273]

[0274]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com