Air spring with variable rigidity and control system based on same

An air spring and control system technology, applied in the direction of spring, spring/shock absorber, gas shock absorber, etc., can solve the problem of occupying the interior space of the car, and achieve the goal of improving space utilization, good controllability and operational stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

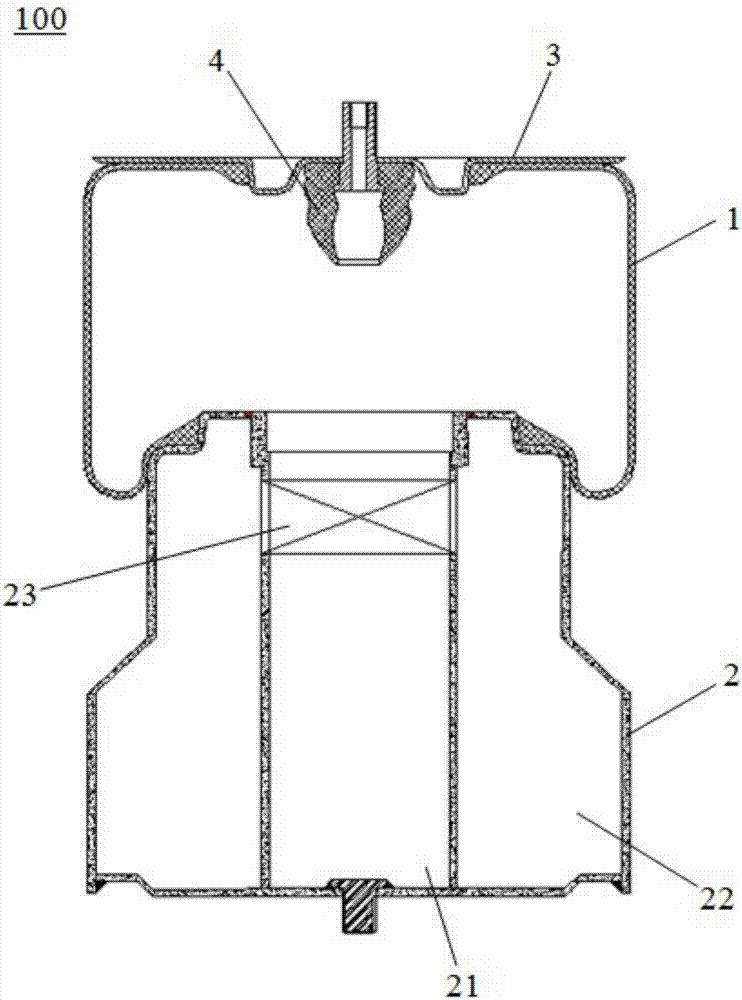

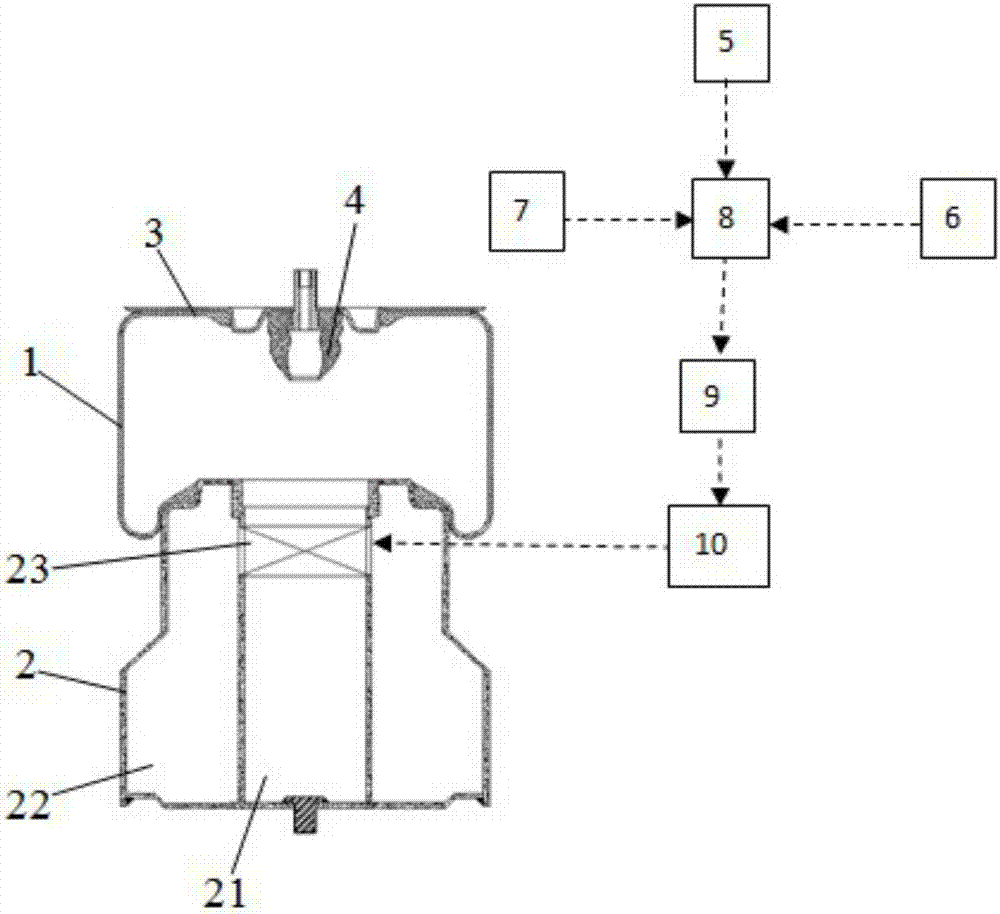

[0031] Please refer to figure 1 , the present embodiment is a variable stiffness air spring 100, which includes an airbag 1, a piston 2, a top plate 3 fixed on the airbag 1, and an anti-collision buffer block 4 located in the airbag 1 and fixed on the top plate 3. An airbag air chamber is formed inside the airbag 1 , and an auxiliary air chamber and a solenoid valve 23 for cutting off or connecting the airbag air chamber and the auxiliary air chamber are arranged inside the piston 2 .

[0032] The inside of the piston 2 is provided with a hole 21 that penetrates up and down and communicates with the airbag chamber. The auxiliary air chamber includes a first auxiliary air chamber surrounded by the hole 21 and a second auxiliary air chamber surrounding the first auxiliary air chamber. Auxiliary chamber 22.

[0033] A communication port (not shown in the figure) connecting the first auxiliary air chamber and the second auxiliary air chamber 22 is provided on the upper part of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com