Plant growing rack with large planting space and high light energy utilization rate and application method of plant growing rack

A technology for plant growth and utilization, which is applied in the field of plant growth racks with high planting space and utilization of light energy, can solve the problems of wasting light energy, wasting light energy, and small light area, so as to reduce the waste of light energy and reduce the amount of light. Scope and effect of saving planting space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

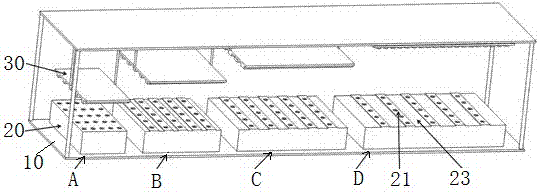

[0049] Example 1 Reference figure 1 with figure 2

[0050] Planting strips are used to grow plants, each of which is an independent individual, its placement direction is perpendicular to the length of the growth frame, and can be moved along the length of the growth frame. In the first growth zone A, multiple planting strips are closely arranged, and there is no gap between two planting strips. The Nth planting basket on each planting strip is lined up in a row in the same direction as the length of the growing frame. A strip LED tube is installed directly above this line of planting baskets. The height of the tube to the plant canopy is L1. The illumination range of the lamp tube is consistent with the final widening range of the plant growing in Zone A, and the lamp light source intensity is Q1.

[0051] In the second growth zone B, there is a longitudinal gap between the two planting strips. The gap width is W. The gap is covered by an opaque baffle. The width W plus the widt...

Embodiment 2

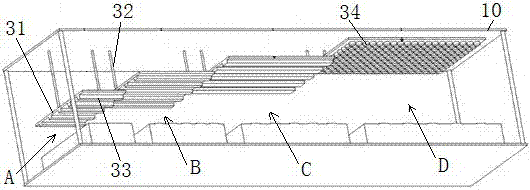

[0056] Example 2 Reference Figure 3 to Figure 5

[0057] Planting strips are used to grow plants, each of which is an independent individual, its placement direction is consistent with the length of the growth frame, and it can move along the length of the growth frame. In the first growth zone A, multiple planting strips are closely arranged, and there is no gap between two planting strips. The Nth planting basket on each planting strip is lined up in a row perpendicular to the length of the growth frame. A strip LED tube is installed directly above the planting basket. The height of the tube to the plant canopy is L5. The illumination range of the lamp tube is consistent with the final widening range of the plant growing in Zone A, and the lamp light source intensity is Q5.

[0058] In the second growth zone B, there is a longitudinal gap between the two planting strips. The gap width is W. The gap is covered by an opaque baffle. The width W plus the width of the planting stri...

Embodiment 3

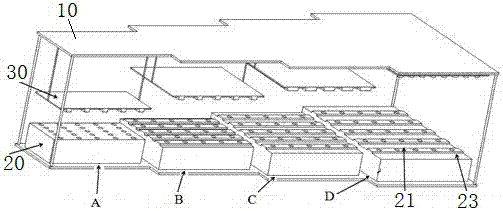

[0063] Example 3 Reference Image 6 with Figure 7

[0064] Plants are planted with planting blocks, each planting block is an independent square individual, movable, and its side length is consistent with the final widening range of the plant growing in the first growth zone A. The multiple planting blocks in the first growth area A are closely arranged, and there is no gap between two adjacent planting blocks. A uniform LED light board is placed directly above all customized blocks. The light emitted by the light board is evenly distributed on the leaf surface of the plant. The irradiation range is consistent with the final leaf development range of the first growth zone A plant. The height to the plant canopy is L9, and the light source intensity of the light board is Q9.

[0065] In the second growth zone B, there is a gap between the horizontal and vertical directions of two adjacent planting blocks. The gap width is W. The gap is covered by an opaque block. The width W plus ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com