Double-screw straw threading extruder

An extruder and twin-screw technology, applied in the direction of feed, food science, application, etc., can solve the problems of lack of efficient straw puffing equipment, etc., and achieve the effects of improving processing and puffing efficiency, increasing energy consumption ratio, and compact and integrated structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

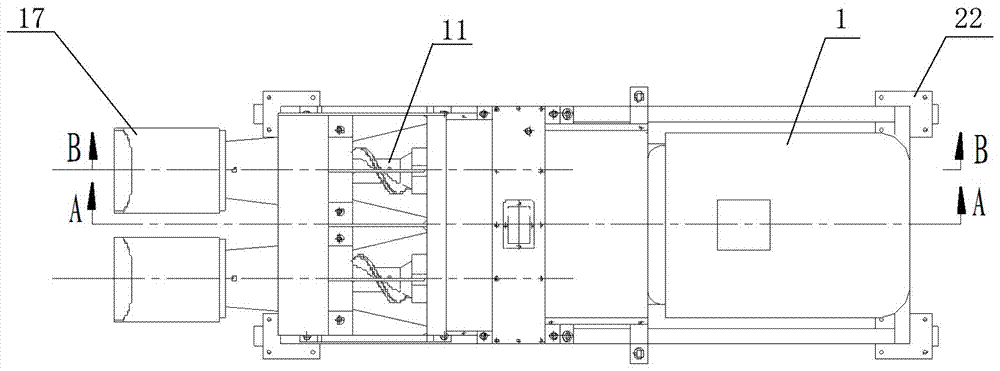

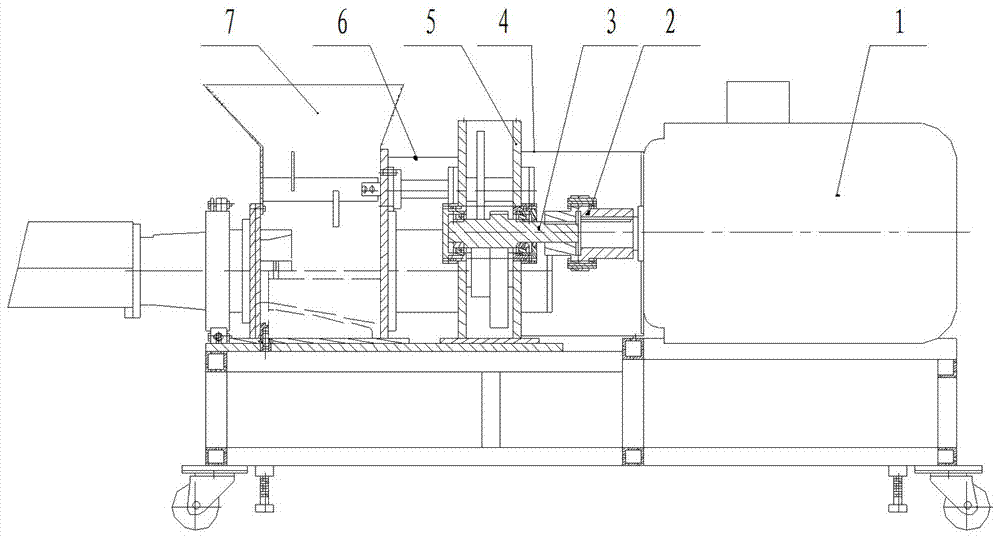

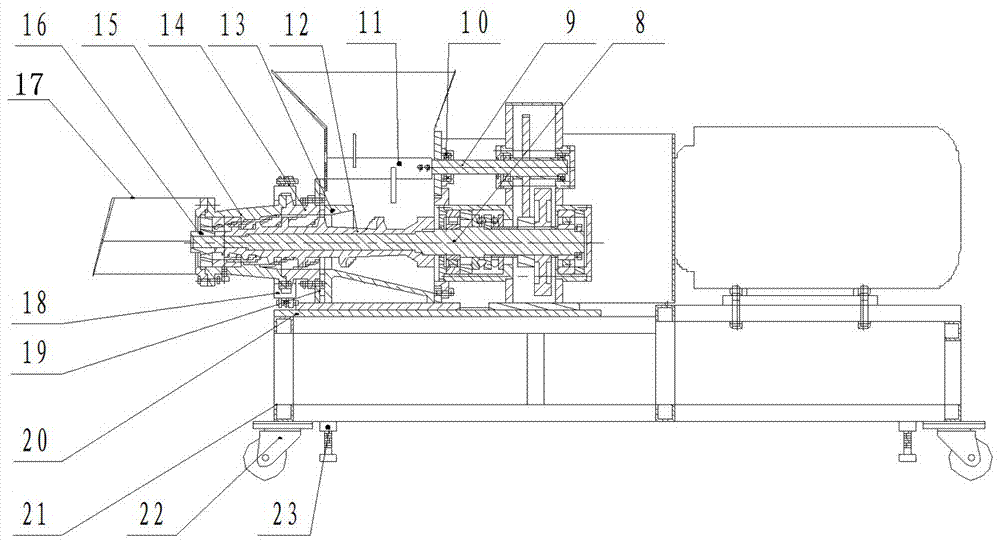

[0022] The twin-screw straw silk puffing machine includes a base frame 21, a base plate 20 is arranged on the base frame 21, a corner wheel 22 and a lock bolt 23 are arranged under the base frame 21, a motor 1 is fixed on the rear of the base frame 21, and a motor 1 is fixed on the front of the base frame 21. Connected with a coupling 2, the coupling 2 is provided with a coupling cover 4, the coupling 2 is connected to the drive shaft 3, the drive shaft 3 is connected to the gearbox 5, and the gearbox 5 is connected to two parallel arrangements located at The top mixing shaft 9 and two puffing shafts 8 located below, the mixing shaft 9 and the puffing shaft 8 all penetrate in the feeding box 19 provided in front of the gearbox 5, and the mixing shaft 9 in the feeding box 19 A mixing plate 11 is set, a hopper 7 is arranged on the top of the feeding box 19 above the mixing shaft 9, and an inherent puffing screw 12 is set on the puffing shaft 8, and the surface of the puffing scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com