Device and method for capturing nitrogen oxide

A technology of nitrogen oxides and capture devices, which is applied in chemical instruments and methods, separation methods, and separation of dispersed particles, can solve problems affecting energy saving, emission reduction, profit reduction, and high cost, so as to promote production, fully respond, and work efficiently. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further explained below in conjunction with specific embodiments.

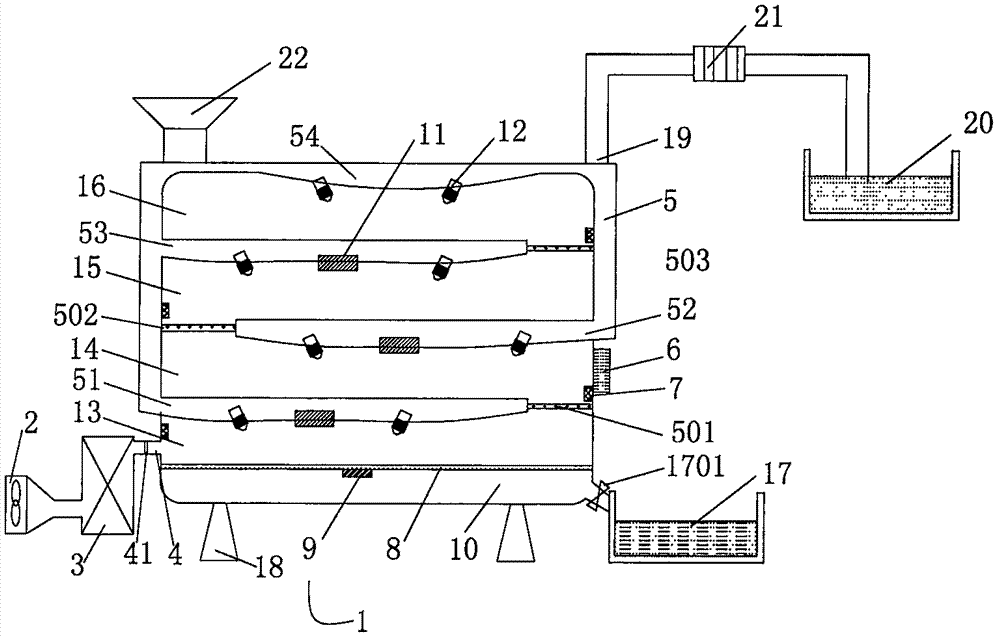

[0029] A nitrogen oxide capture device, comprising a reactor body 1, a blower 2 is provided on the outer side of the lower end of the reactor body 1, and the blower 2 is connected to the inlet end of an air compressor 3 through a pipe, and the outlet of the air compressor 3 The end is connected to the air inlet 4 of the reactor, and an air inlet check valve 41 is provided on the air inlet 4 of the reactor.

[0030] The outer side of the upper end of the reactor body 1 is provided with a liquid storage chamber 5, which includes a top layer liquid storage chamber 54 which is staggered and laterally extended into the reactor body 1 to form a lower liquid storage chamber 51 and a middle liquid storage chamber 52 and the upper liquid storage chamber 53, the lower liquid storage chamber 51, the middle liquid storage chamber 52, the upper liquid storage chamber 53, and the top liquid s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap