Micro carrier cleaning device

A technology for cleaning equipment and microcarriers, which is applied in the field of medical devices and can solve problems such as cross-contamination, insufficient adsorption, and easy loss of microcarriers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention are described in detail below:

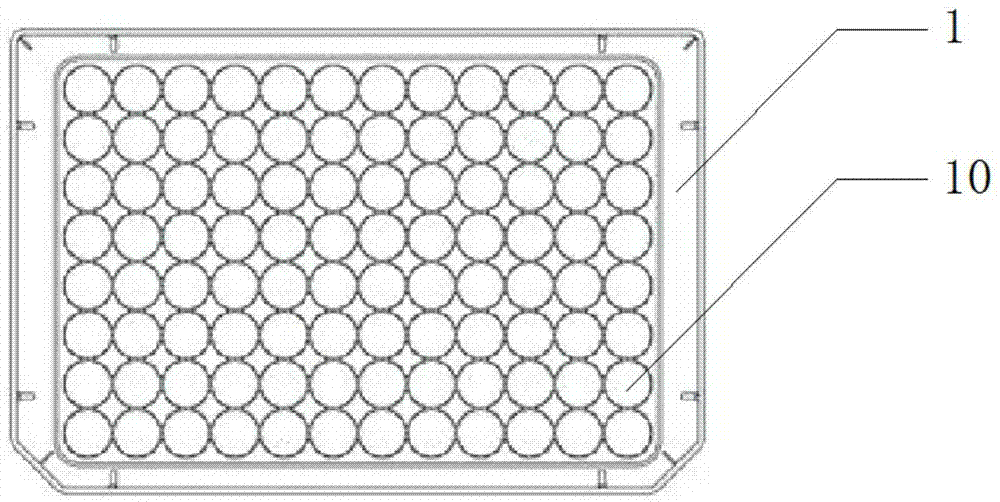

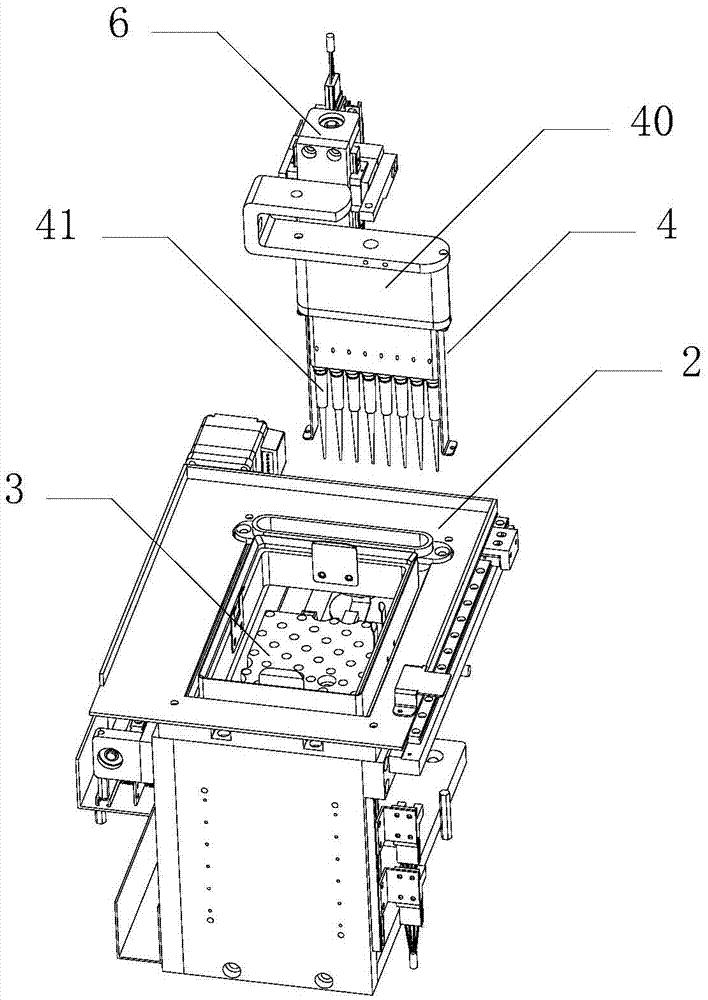

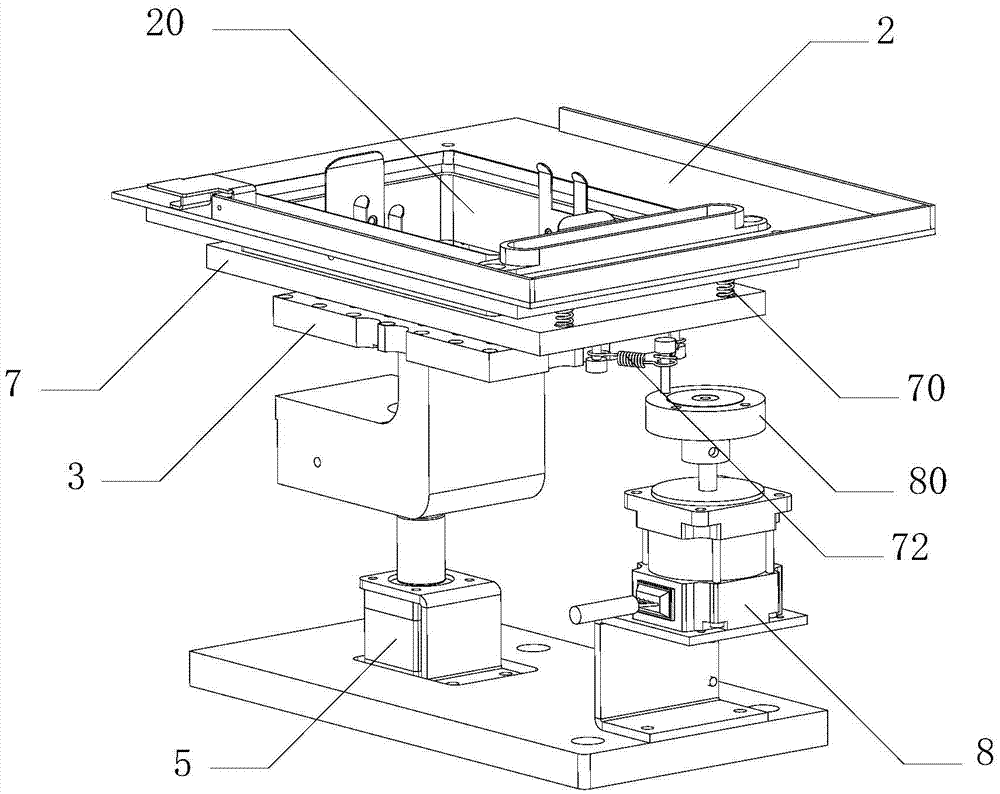

[0028] Such as figure 1 , 2 As shown in . A reaction cup 10 with the mouth upwards, the reaction plate frame 2 is provided with an installation hole 20 for placing the sample plate 1, the microcarrier adsorption device 3 is arranged under the reaction plate frame 2, and the micro-carrier adsorption device 3 is arranged below the reaction plate frame 2. The carrier adsorption device 3 includes a substrate and a plurality of magnets arranged on the substrate, the plurality of magnets are respectively arranged corresponding to the plurality of cuvettes 10 , and the cleaning device 4 is arranged above the reaction rack 2 . In the above-mentioned microcarrier cleaning equipment, the sample disc 1 is installed on the installation hole 20 of the reaction disc rack 2, and the cleaning device 4 positioned above the reaction disc rack 2 can clean the cuvette 10 on the sample disc 1. The cuvette 10 is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com