Dead head production device with automatic assembling and material taking functions

A technology of automatic assembly and production equipment, which is applied in the direction of casting molding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of low production efficiency and inability to realize automatic assembly and molding, and achieve the effect of convenient automatic assembly and flexible setting mode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

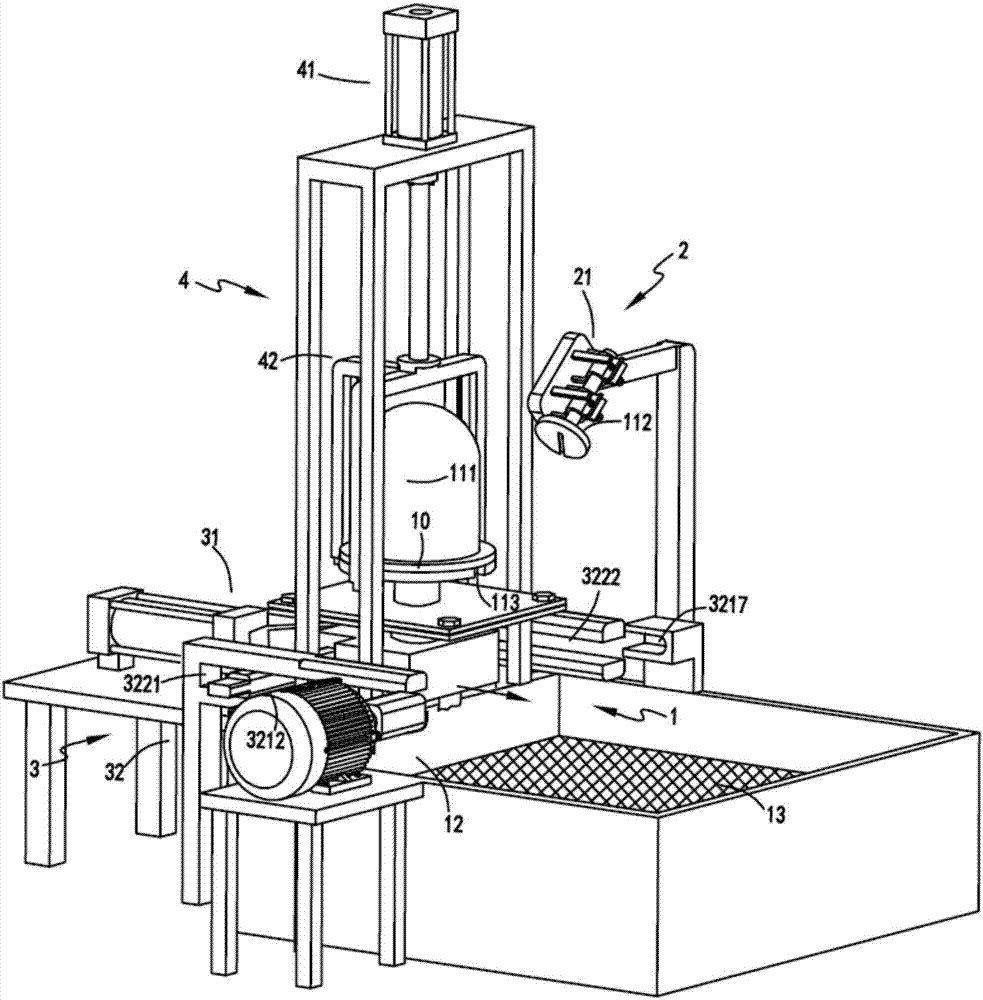

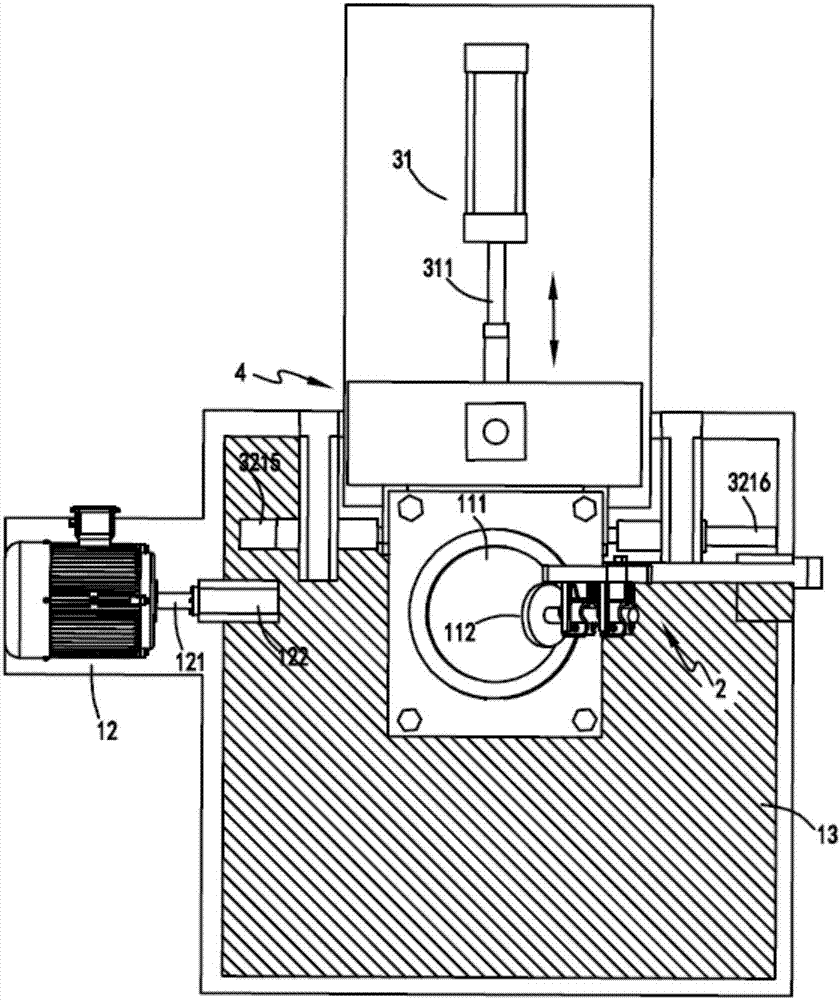

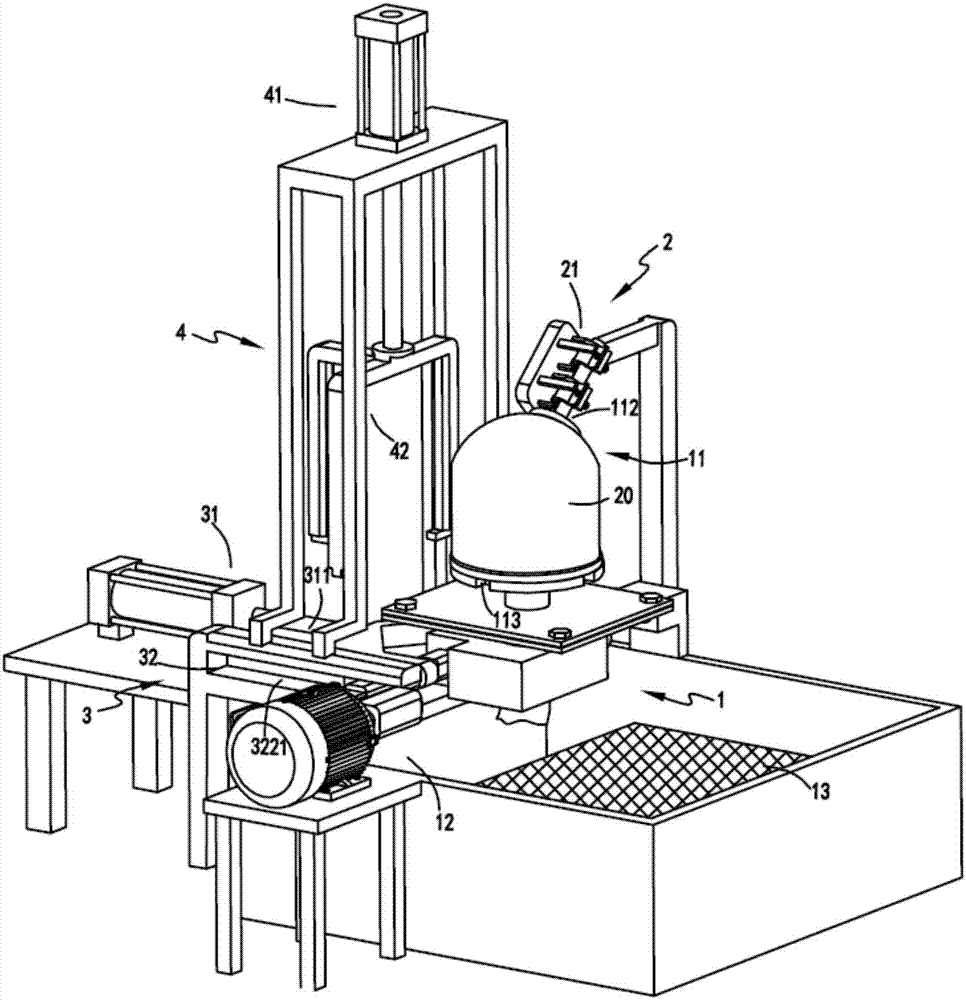

[0038] figure 1 It is a schematic structural diagram of the initial state of the riser production equipment with automatic assembly and reclaiming functions, figure 2 It is a top view diagram of the riser production equipment with automatic assembly and reclaiming functions, image 3 It is a schematic diagram of the structure of the riser production equipment with automatic assembly and reclaiming functions when it is automatically separated, Figure 4 It is a schematic diagram of the push-pull part and the forming part, Figure 5 It is a schematic diagram of the enlarged structure when the forming mold and the forming cover are matched, Figure 6 It is a schematic diagram of the structure when the rotating device drives the forming device to rotate, Figure 7 It is a structural schematic diagram of the clamping part of the molding cover, Figure 8 Schematic diagram of the structure of the molded cover. Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5...

Embodiment 2

[0056] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 and Figure 8 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between the second embodiment and the first embodiment is that the forming cover 112 includes a cover body 1122 and a clamping rod 1123 for fastening with the clamping unit 21; the end of the clamping rod 1123 A limit rod 1124 is also provided, and correspondingly, a limit hole 221 cooperating with the limit rod 1124 is provided on the support frame 22, and the cooperation between the limit hole 221 and the limit rod 1124 can make The position of the forming cover 112 is fixed, avoiding the situation that the clamping unit 21 cannot firmly clamp the forming cover 112 due to the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com