Electrified replenishing device for transformer oil additive

A technology of transformer oil and additives, applied in switchgear, distribution device, special distribution device, etc., can solve the problems of affecting the reliability of the main transformer and the power supply index, increasing the operating cost and maintenance cost, and cumbersome procedures. Performance and electrical performance, avoid equipment safety hazards, and simplify the effect of operating procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

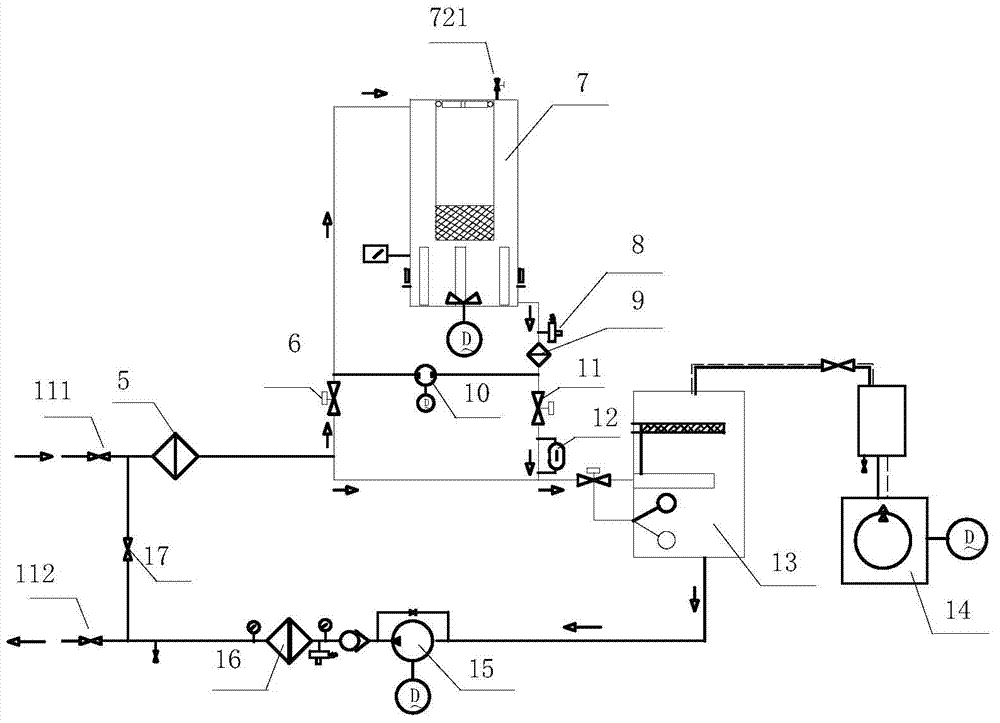

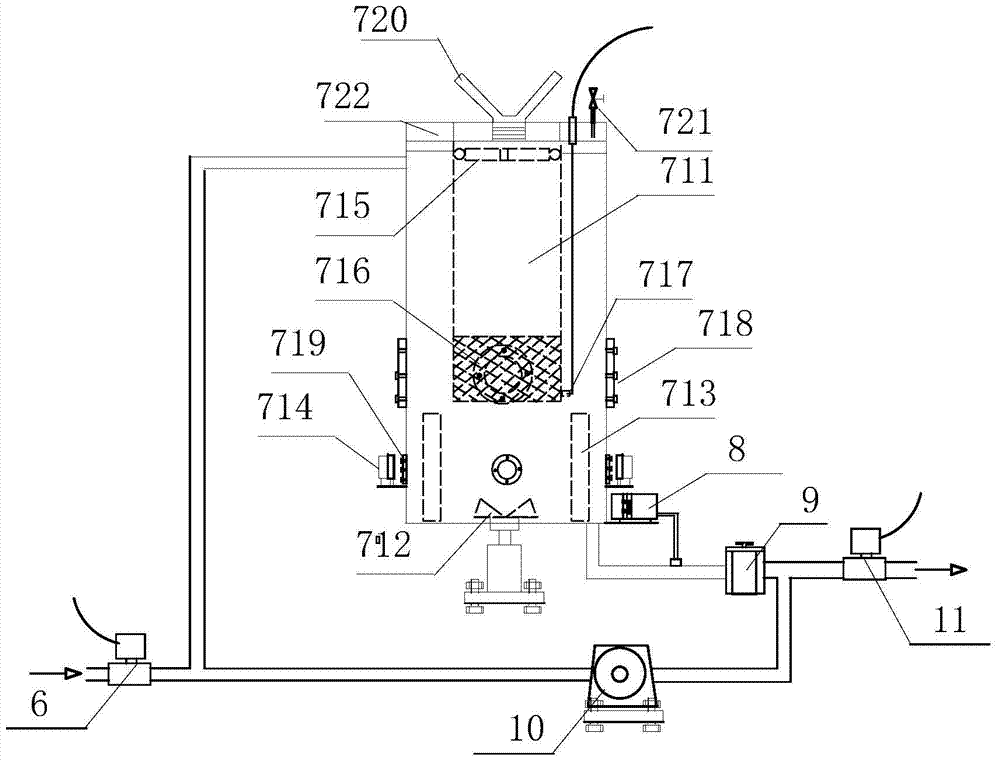

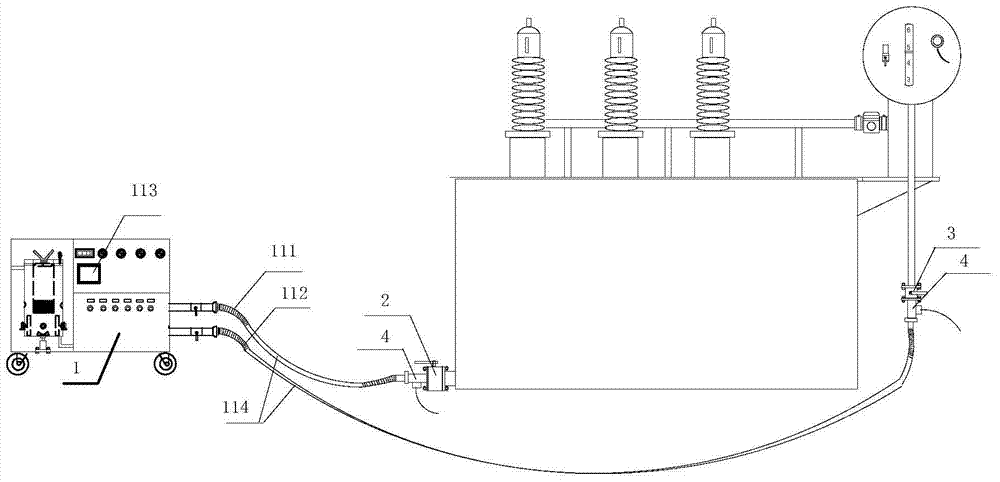

[0033] a kind of like figure 1 , figure 2 The transformer oil additive charging device shown includes the oil inlet valve 111 of the charging device, the oil outlet valve 112 of the charging device, the automatic control monitoring and reporting system 113, the oil pipe 114, the induction shut-off valve 4, the device inlet Oil port filter 5, additive dissolving tank oil inlet valve 6, additive dissolving tank 7, feeder 711, stirring pulsator 712, ceramic heater 713, infrared photosensitive detector 714, cast iron gravity cover 715, stainless steel screen 716, position Magnetic induction contact 717, observation window 718, detection window 719, self-locking handle 720, air release valve 721, outer cover 722, pressure controller 8, additive filter 9, recoil oil pump 10, additive dissolving tank normally closed oil outlet valve 11 , flow controller 12, vacuum tank 13, high-efficiency vacuum pump 14, low-speed oil discharge pump 15, device oil outlet filter 16, inlet and outlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com