Unloading device for monocrystalline silicon wafer production workshop

A technology for production workshops and monocrystalline silicon wafers, applied to fine working devices, manufacturing tools, stone processing equipment, etc., can solve problems such as dripping on the ground and deterioration of the workshop environment, and achieve a reduction in floor space and good practicality High performance, easy and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing of description, the concrete structure of unloading device in the present invention is done to illustrate:

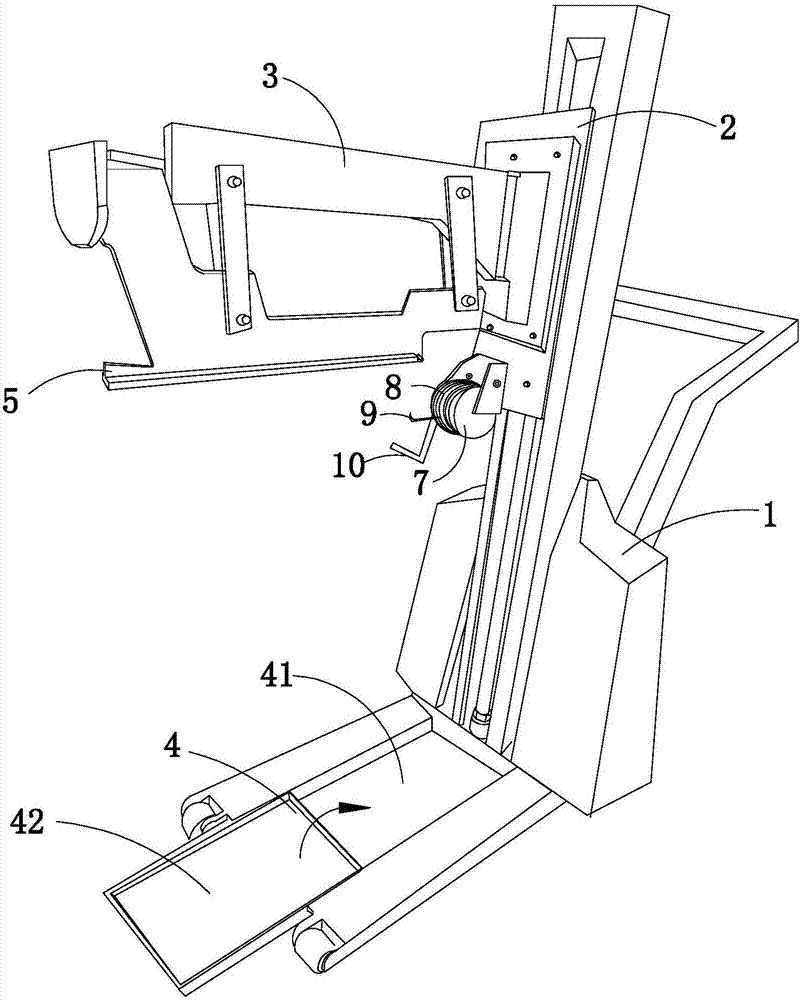

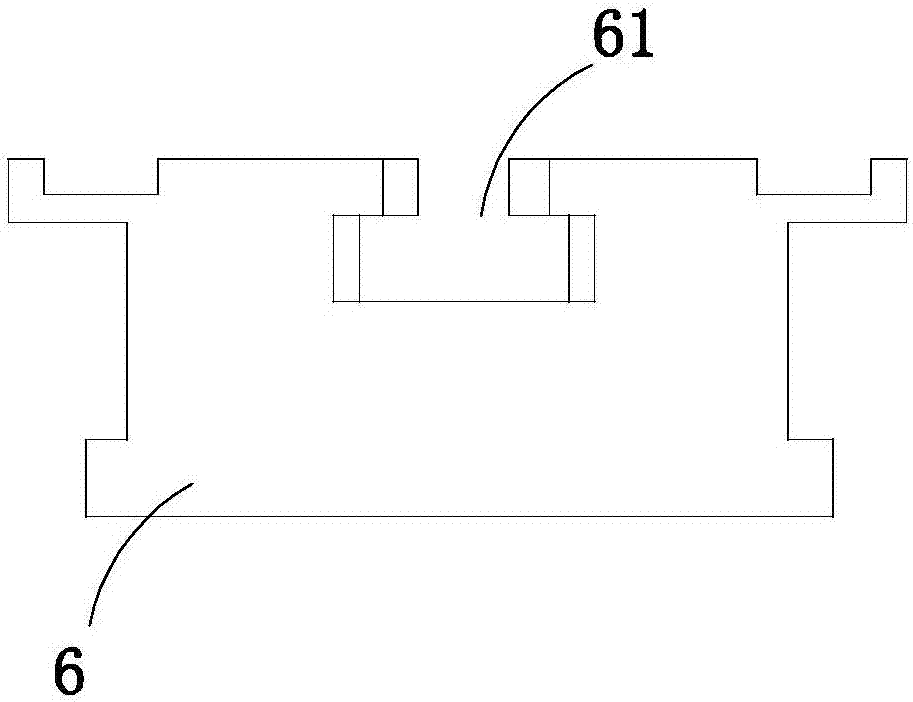

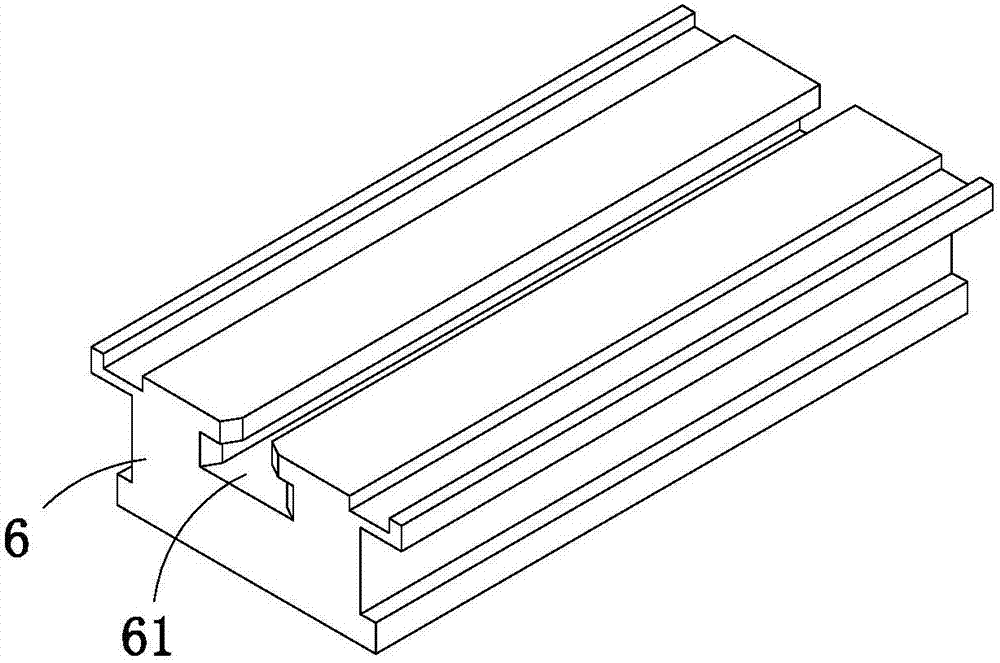

[0016] A blanking device for a monocrystalline silicon wafer production workshop, such as figure 1 As shown, it includes a frame 1 and rollers installed on the bottom of the frame 1, the frame 1 is provided with a lifting frame 2 that can move up and down and a drive mechanism that drives the lifting frame 2 to move up and down, the The driving mechanism can adopt a screw drive mechanism (motor-driven or hand-driven) or a cylinder, and the lifting frame 2 is provided with an arm frame 3 for matching with the stick tooling 6; the bottom of the frame 1 is fixed with a A mortar collection box 4 located below the arm frame 3, the mortar collection box 4 has an opening facing upwards. When the monocrystalline silicon wafer production workshop in this embodiment uses the unloading device to unload the sticky tooling from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com