A kind of oxidation method of hydrogen peroxide production process

A production process and technology of hydrogen peroxide, applied in the field of oxidation, can solve the problems of large oxidation tower, long residence time of materials in the oxidation tower, and reduced oxidation rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

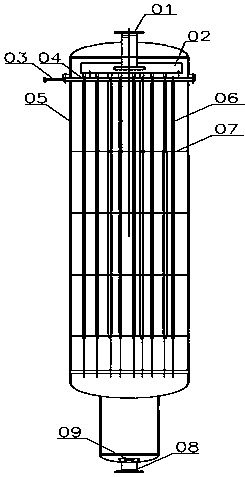

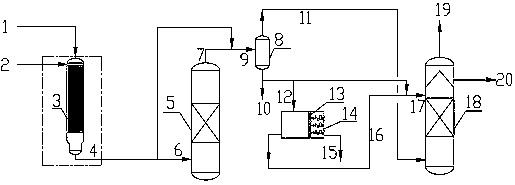

[0034] The hydrogenation liquid with a hydrogen effect of 7.5g / L and a tetrahydroanthraquinone content of 42g / L (total effective anthraquinone content of 118g / L) is introduced into the pre-processor together with the oxygen-enriched gas for contact association reaction. The contact time is 80s. After the intermediate association is generated, it is introduced into the oxidation reactor (I), and after the gas-liquid co-current reaction occurs, it is introduced into the gas-liquid separator, and then flows out after gas-liquid separation. The oxidation reactor (I) has a diameter of 300mm, a height of 1400mm and a total volume of 0.09m 3 . The flow rate of the hydrogenated liquid at the bottom of the oxidation reactor (I) is 1.5m 3 / h, the amount of oxygen-enriched gas with an oxygen content of 40v% is 24Nm 3 / h, liquid (m 3 / h) Gas (Nm 3 / h) ratio is 1:16, the reaction temperature is 47-50°C, the reaction pressure is 0.32 MPa, and the residence time is ~8 minutes. The resul...

Embodiment 2

[0036] The hydrogenation liquid with a hydrogen effect of 9.2g / L and a tetrahydroanthraquinone content of 50g / L (total effective anthraquinone content of 165g / L) is introduced into the preprocessor together with 40% oxygen-enriched gas for contact association reaction. The contact time is After 150s, the intermediate associates are formed and introduced into the oxidation reactor (I), and the gas-liquid co-current reaction occurs and then introduced into the gas-liquid separator, and the hydrogenated liquid after gas-liquid separation is then introduced into the oxidation reactor (II), in the reactor After the gas-liquid countercurrent reaction occurs, the gas-liquid separation is carried out at the top, and the separated oxidation tail gas and oxidation liquid are led out of the device respectively. The oxidation reactor (I) has a diameter of 400mm, a height of 1800mm and a total volume of 0.22m 3 . The oxidation reactor (II) has a diameter of 300mm, a height of 1400mm, and ...

Embodiment 3

[0038] The hydrogenation liquid with a hydrogen effect of 10.5g / L and a tetrahydroanthraquinone content of 72g / L (total effective anthraquinone content of 170g / L) is introduced into the preprocessor together with 40% oxygen-enriched gas for contact association reaction. The contact time After 220s, the intermediate associates are generated and introduced into the oxidation reactor (I), after the gas-liquid co-current reaction occurs, they are introduced into the gas-liquid separator, and the hydrogenated liquid after gas-liquid separation is introduced into the H 2 o 2 Membrane separator, will produce part of the H 2 o 2 After separation, the obtained hydrogenated liquid is further introduced into the oxidation reactor (II), and gas-liquid separation occurs at the top after a gas-liquid countercurrent reaction occurs in the reactor, and the separated oxidation tail gas and oxidation liquid are respectively drawn out of the device. The oxidation reactor (I) has a diameter of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com