Lining paper for constant-moisture quality-aroma reserving aluminum-free cigarette and manufacturing process of lining paper

A technology of lining paper and aroma-preserving layer for cigarettes, applied in the field of papermaking, can solve the problems of mildew and affect the quality of cigarettes, and achieve the effect of balancing moisture and maintaining quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

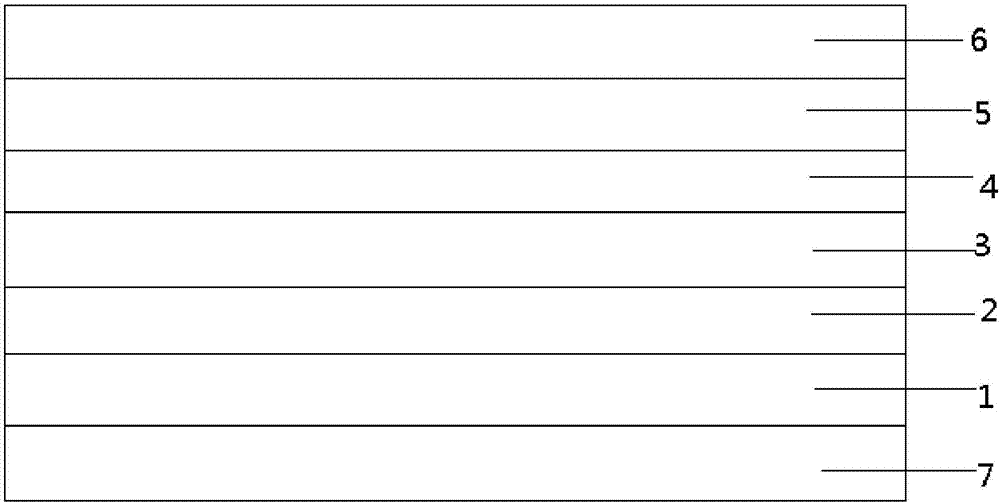

[0039] A kind of lining paper for aluminum-free cigarettes with constant humidity, high quality and fragrance, its structure is as follows: figure 1As shown, it includes a base paper layer 1 and a moisturizing and fragrance-retaining layer 2, a hot-melt sealing layer 3, a water-based sealing layer 4, a water-based printing layer 5 and a water-based protective layer that are sequentially stacked on the upper surface of the base paper layer 1 from inside to outside. 6. A moisture return layer 7 is formed on the lower surface of the base paper layer 1 . The manufacturing steps of described lining paper comprise:

[0040] 1) The particle size is 50μm and the specific surface area is 50g / m2 by roller coating 2 The ceramic powder is coated on the upper surface of the base paper layer 1 to form a moisturizing and fragrance-preserving layer 2, wherein the dry coating amount of the moisturizing and fragrance-preserving layer 2 is 3g / m 2 , the pit depth of the anilox roller used in th...

Embodiment 2

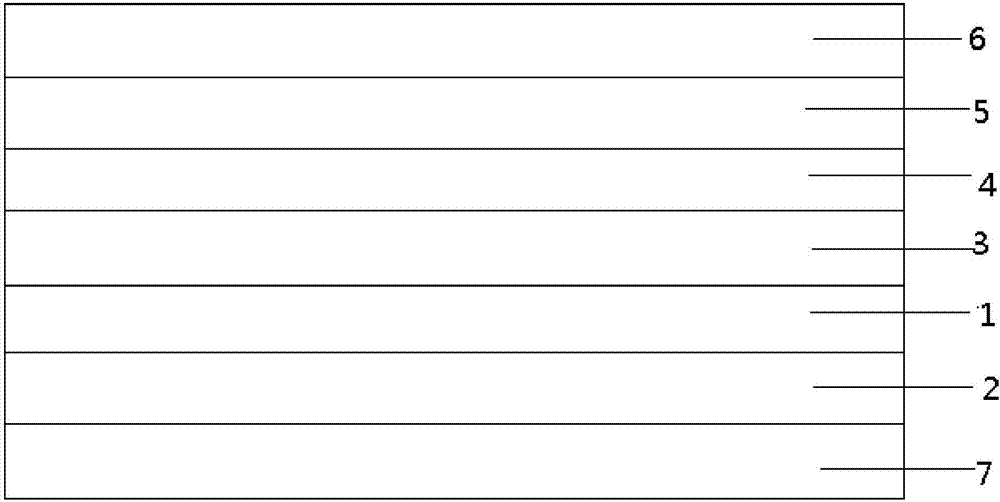

[0047] A kind of lining paper for aluminum-free cigarettes with constant humidity, high quality and fragrance, its structure is as follows: figure 2 As shown, it includes a base paper layer 1 and a hot-melt sealing layer 3, a water-based sealing layer 4, a water-based printing layer 5 and a water-based protective layer 6 that are sequentially stacked on the upper surface of the base paper layer 1 from the inside to the outside. The lower surface of 1 is sequentially formed with a moisturizing and fragrance-retaining layer 2 and a moisture return layer 7 from the inside to the outside. The manufacturing steps of described lining paper comprise:

[0048] 1) Coating a hot-melt polymer material with a hot-melt temperature of 120° C. on the upper surface of the base paper layer 1 to form a hot-melt sealing layer 3 by means of slit coating, and the temperature of the slit coating is 120° C. ℃, the coating weight is 15g / m 2 ;

[0049] 2) By means of gravure printing, the polymer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dry coat | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Melting temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com