Computer generated hologram based on liquid crystal materials and manufacturing method thereof

A technology of computational holograms and liquid crystal materials, applied in the field of computational holograms, can solve the problems of complex production, long cycle, and expensive, and achieve the effect of short processing cycle and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] The liquid crystal material-based computational hologram disclosed in this embodiment is suitable for the laser interferometry detection of surface error of high-precision optical elements, especially for complex aspheric surface error detection of laser interferometry.

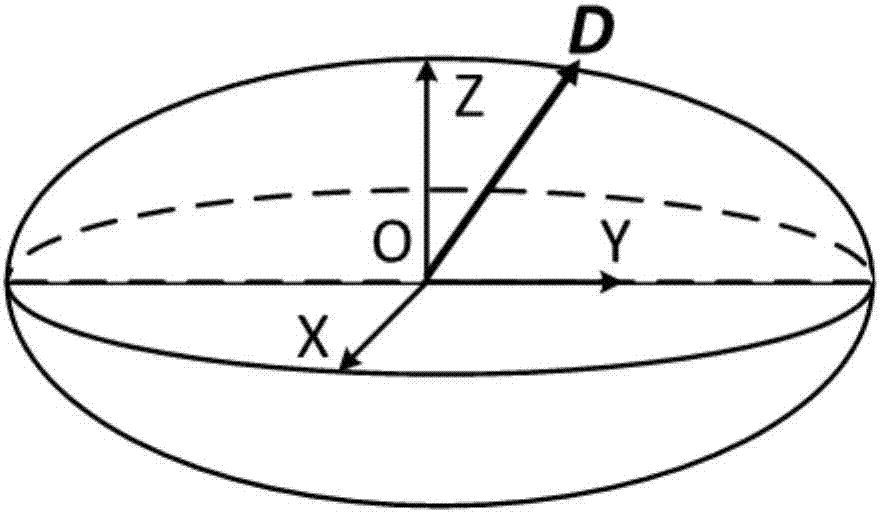

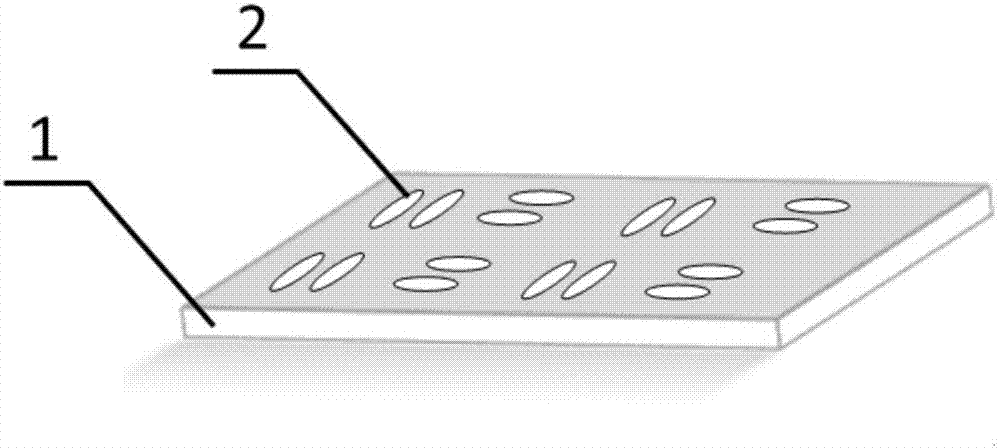

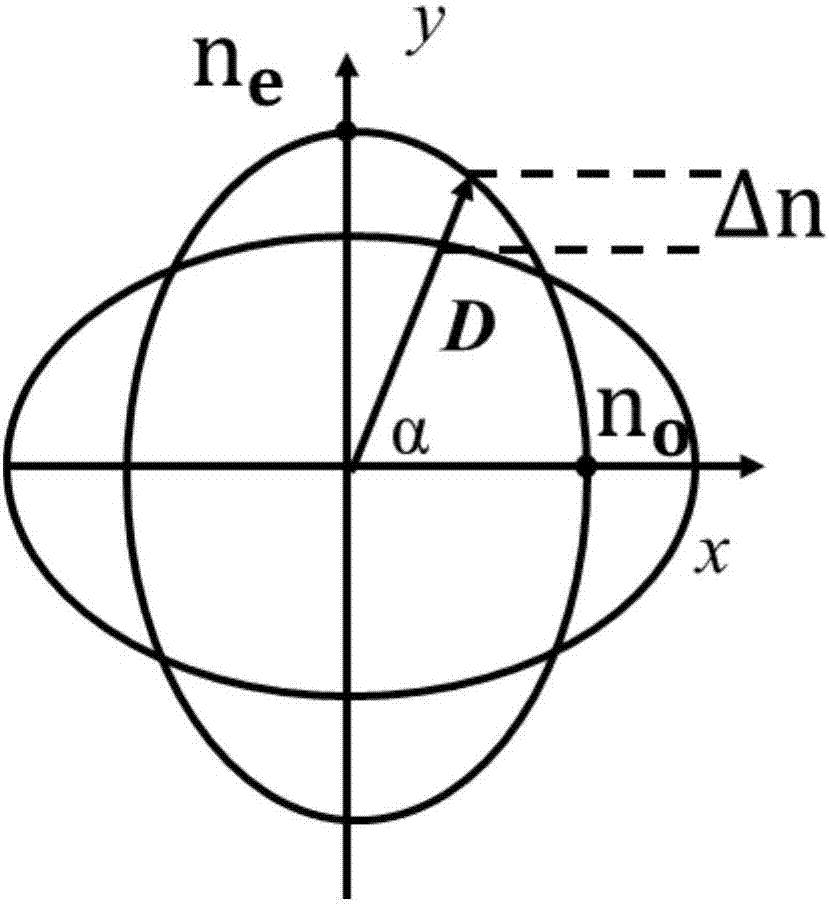

[0057] A liquid crystal material-based computational hologram disclosed in this embodiment includes a glass substrate 1 with uniform transmittance and a liquid crystal material 2 coated on the substrate 1 . The direction of the liquid crystal molecules in the adjacent stripes of the liquid crystal material 2 is controlled by the optical control orientation technology. The stripes will have different refractive indices for the incident light with the same known incident direction and polarization direction. Material 2 will generate a phase difference, that is, form a computational hologram with a fixed phase difference that compensates for the incident laser light.

[0058] The glass substrate with unif...

Embodiment 2

[0094] The aspheric surface to be measured and the measuring optical path in this embodiment are the same as those in Embodiment 1, the only difference is that the thickness of the selected liquid crystal material 2 is different. In the first embodiment, the thickness of the liquid crystal material 2 is selected as 2 microns, and in this embodiment, the thickness of the liquid crystal is selected as 6 microns.

[0095] The fabrication method is the same as above, after four steps of calculation and design, the final computational hologram is shown in Figure 8(a) and Figure 8(b). 8(a) is the pattern distribution of the liquid crystal computational hologram, and Fig. 8(b) is the enlargement of the central area. Compared with the design results in Example 1, it can be seen that in this example, because the thickness of the liquid crystal material 2 is set differently, the final stripe distribution is obviously sparse, which will greatly reduce the difficulty and processing cost o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com