Method and device for dual-mode depth measurement

A depth measurement, dual-mode technology, used in measurement devices, distance measurement, line-of-sight measurement, etc., can solve problems such as different measurement ranges and depth accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

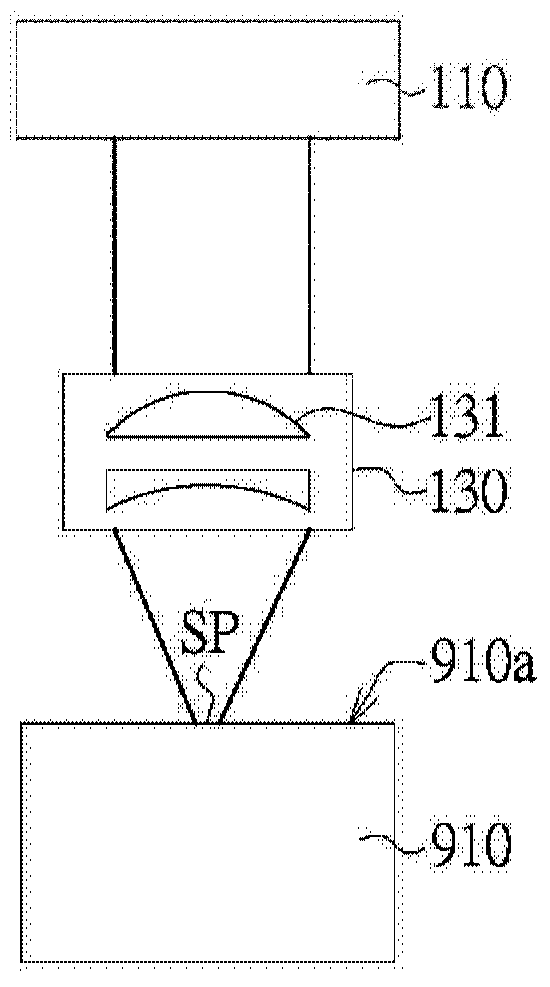

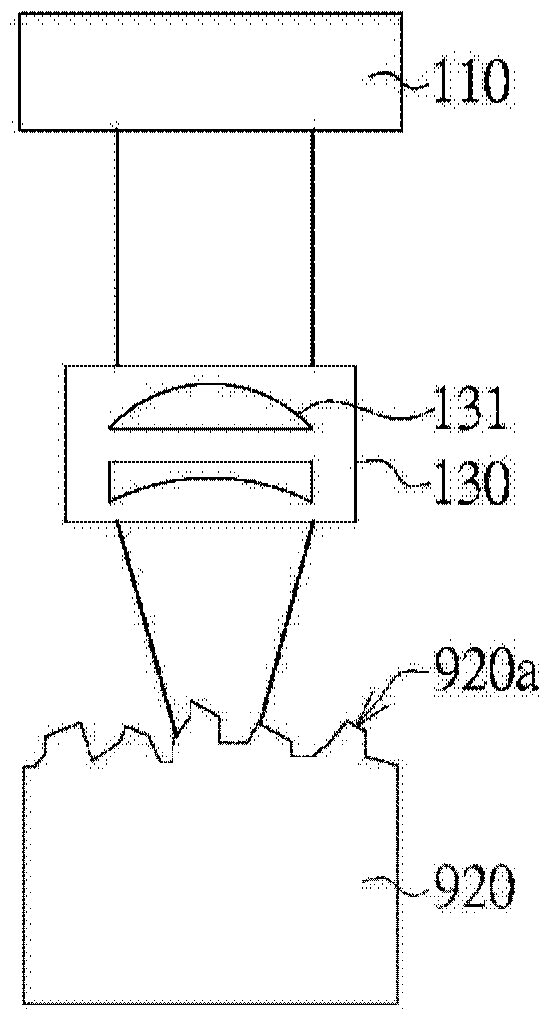

[0034] The invention relates to a device and method for dual-mode depth measurement. Users can perform depth measurement on the surface of an object with mirror reflection or on the surface of an object with texture, and the user can adjust the desired depth measurement accuracy and working range. . The device and method for dual-mode depth measurement of the present invention can obtain the relative distance of the detected object with high precision. figure 1 and figure 2 A schematic diagram showing the light source irradiating the surface of an object in different modes, figure 1 A schematic diagram of the light source 110 and the light emitting optical system 130 in the depth from defocus (DFD) mode is shown. exist figure 1 Among them, an object 910 is, for example, a hard disk or a wafer, which has a mirror-reflecting surface 910a, and the surface 910a is hereinafter referred to as a mirror surface. Such as figure 1 As shown, the light emitting optical system 130 fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com