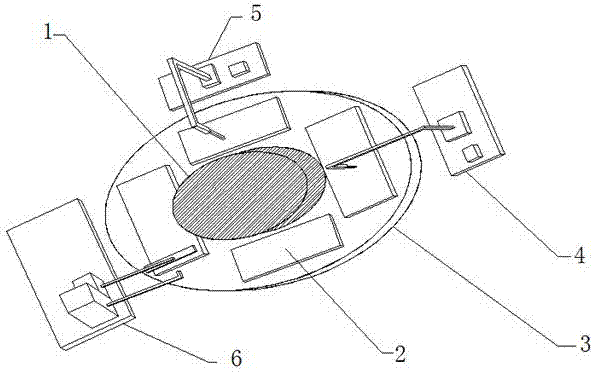

Disc-type automated test apparatus

An automated testing, disc-type technology, applied in the testing of mechanical parts, the testing of machine/structural parts, measuring devices, etc., can solve the problems of waste of manpower, large errors in human testing, noise pollution, etc., to improve cleaning efficiency, High test efficiency and resource saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

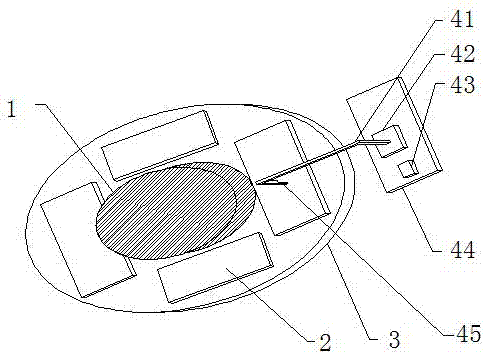

[0031] Specific implementation method: the user puts the keyboard on the upper end surface of the placement table 2, connects the power output component 1 with an external power supply, the external power supply transmits electric energy to the power output component 1, and the power output component 1 transmits electric energy to the motor through wires, and the motor The electrical energy is converted into mechanical energy, and the turntable 3 is driven to rotate clockwise, and the turntable 3 drives the placement table 2 to rotate by friction.

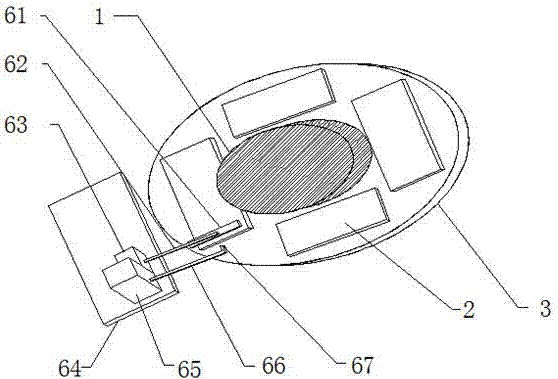

[0032] When the placing table 2 rotates to the lower end of the brush 61, the power output member 1 transmits the electric energy to the electric cylinder three 63 and the compressor 65 through the wire, and the electric cylinder three 63 drives the support frame 62 to move backward, and the support frame 62 drives the brush 61 Moving backwards, the brush 61 cleans the keyboard below, while the compressor 65 converts electrical ener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com