A digitally controlled brick pushing device and method for an edge grinder

A technology of edging machine and brick pushing mechanism, which is applied in the direction of computer control, program control, general control system, etc., can solve the problems of personal safety accidents, damage of brick pushing mechanism, poor precision, etc., and achieve strong market promotion prospects, Save labor costs and have strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

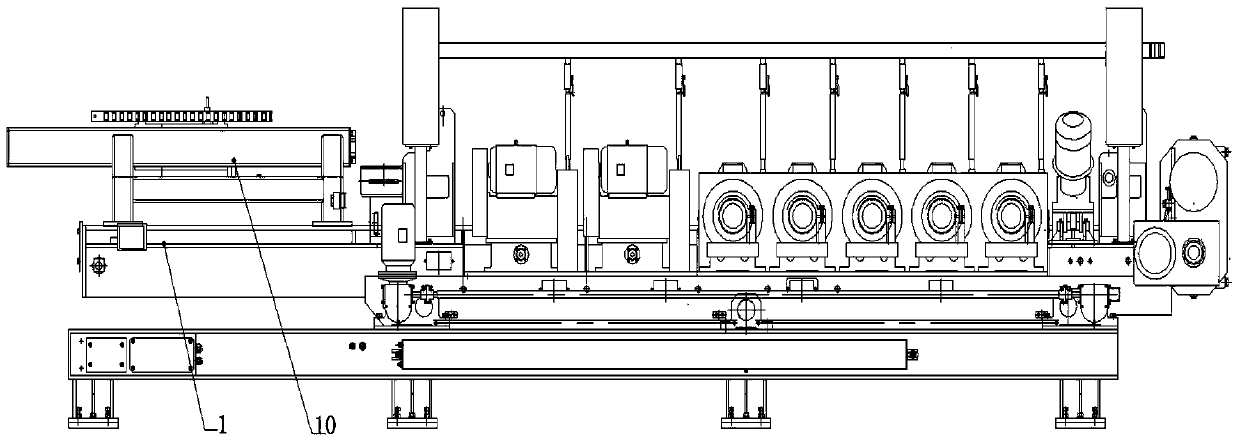

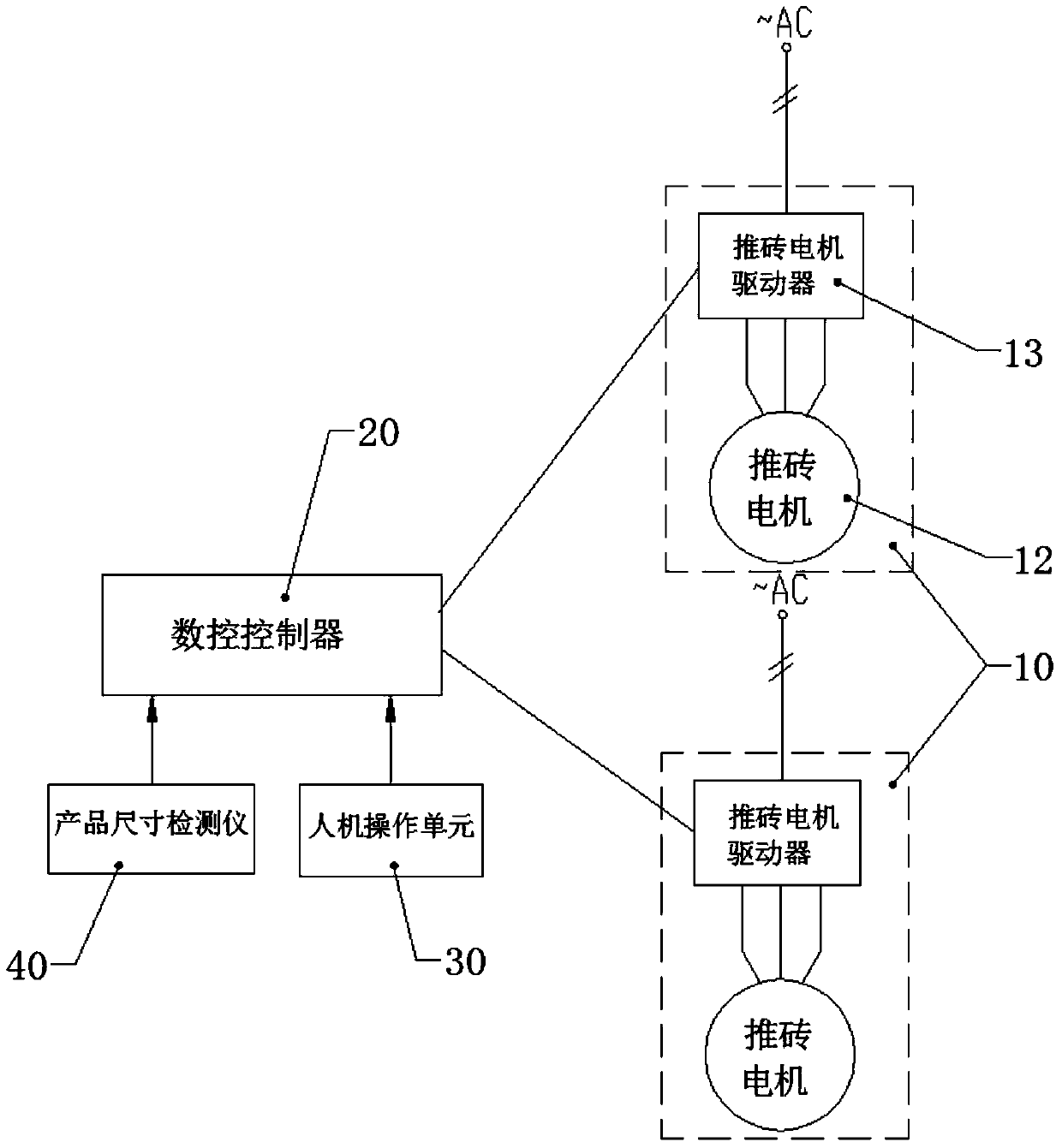

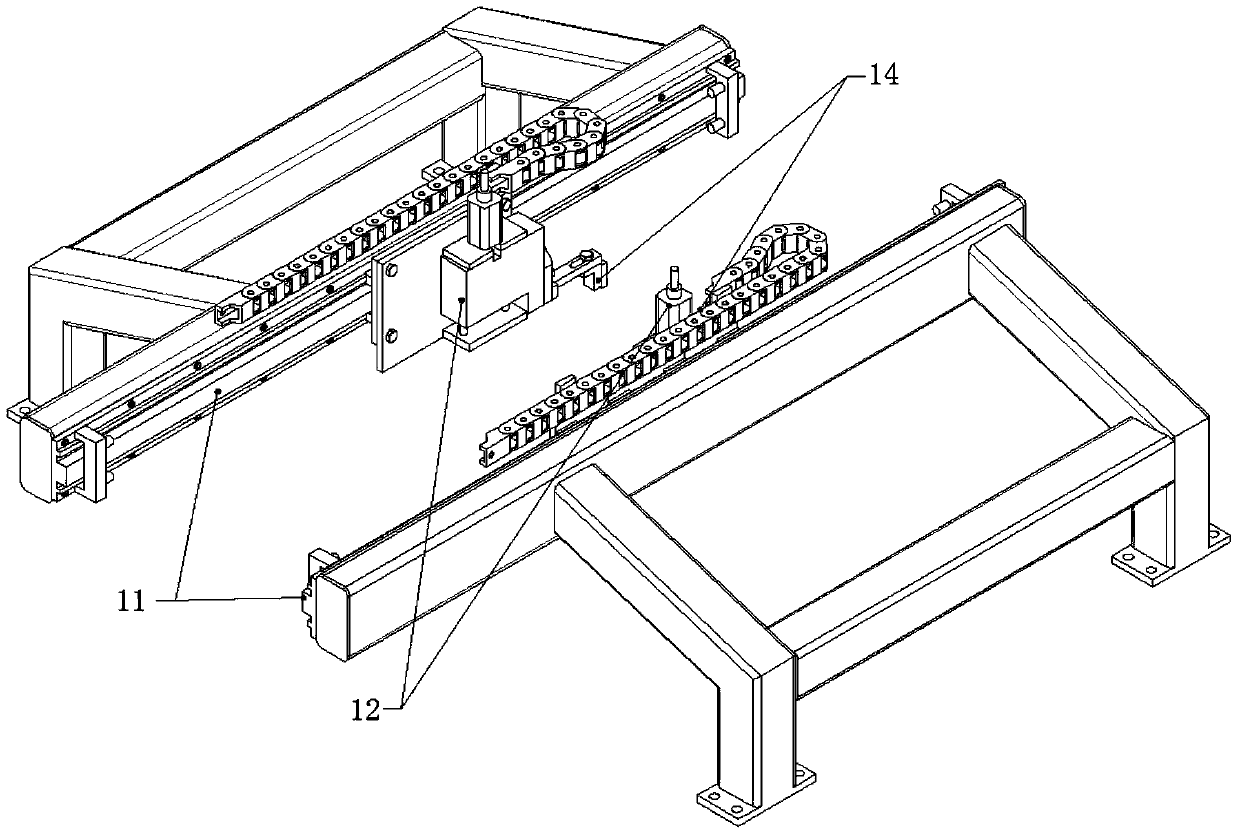

[0030] see Figure 1-Figure 4 . figure 1 It is a schematic diagram of the installation position of the brick pushing mechanism. figure 2 It is a schematic diagram of the connection relationship of the CNC brick pushing device of the edging machine. image 3 It is a structural schematic diagram of the brick pushing motor and the brick pushing claw. Figure 4 It is a schematic diagram of the position of brick pushing claws and brick grinding products. The invention provides a numerically controlled brick pushing device for an edge grinder, comprising

[0031] --Brick pusher mechanism 10, described brick pusher mechanism 10 is arranged on the frame of edging machine 1, described brick pusher mechanism 10 comprises two linear guide rails 11, each is provided with a brick pusher motor 12 on described linear guide rail 11 , the brick pushing motors 12 are respectively connected with a brick pushing motor driver 13, the brick pushing motors 11 drive the brick pushing claws 14 fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com