Semiconductor wafer box particle detection method

A particle detection and semiconductor technology, applied in the field of semiconductor wafer box particle detection, can solve problems such as affecting the electrical performance of integrated circuits, reducing product yield, and product quality loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] This embodiment is described by taking a 12-inch silicon wafer box that can hold 25 wafers as an example.

[0025] 1. Take 12 pieces of 12inch polished silicon wafers and 4 wafer boxes (front opening wafer box or wafer transport box (FOUP / FOSB));

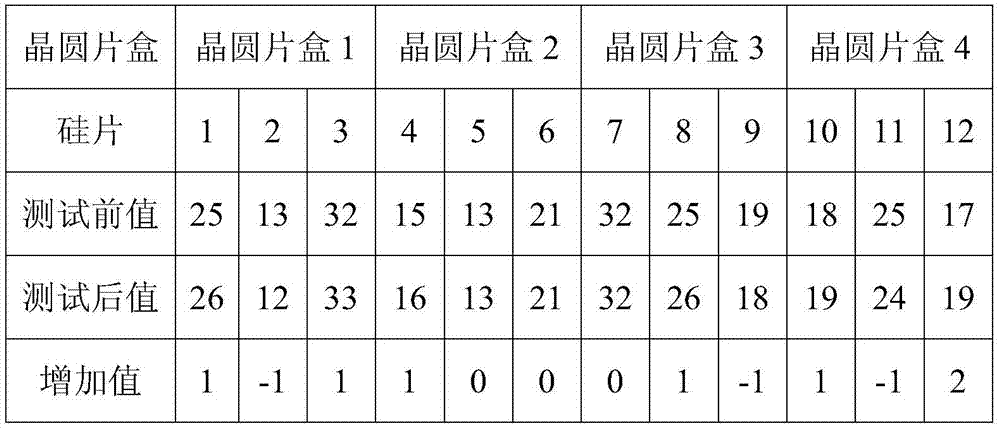

[0026] 2. Use the surface particle tester KLA Tencor SP1 to test the surface particles of 12 pieces of 12inch polished silicon wafers, and record the previous value of the data;

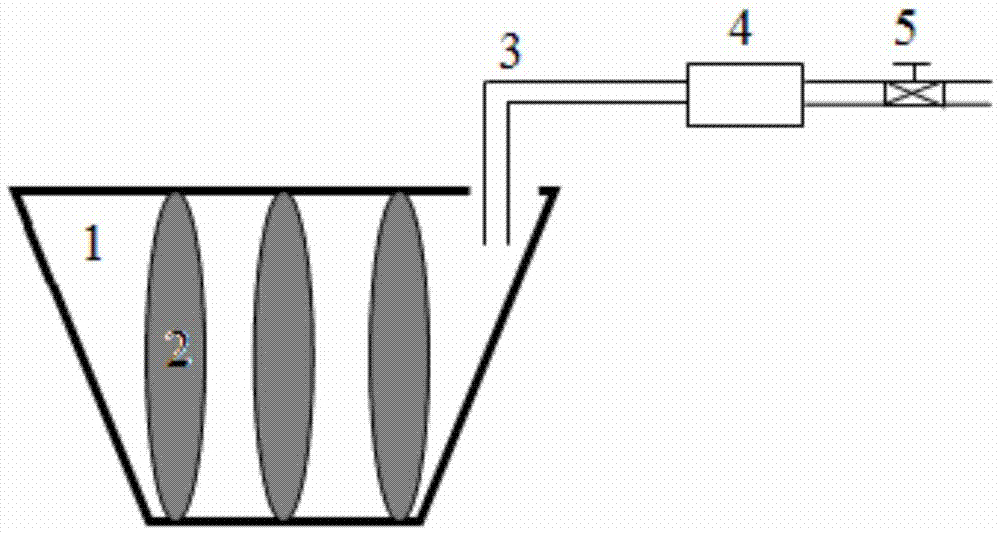

[0027] 3. Divide 12 pieces of 12inch polished silicon wafers into four groups, put them into the two ends and middle positions of 4 wafer cassettes (FOUP / FOSB) respectively, cover the wafer cassettes halfway, leave a certain gap, and then place them separately Put the air tube into the gap between the four wafer cassettes (be careful not to touch the silicon wafer), turn on the switch, and blow air for 1 minute each;

[0028] 4. Take out 12 pieces of 12inch polished silicon wafers, and then use the surface particle tester KLA Tencor SP1 to test the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com