Corn washing and impurity removing device

A corn and water washing technology, which is applied in the direction of solid separation, wet separation, chemical instruments and methods, etc., can solve the problems of incomplete removal of impurities and poor washing effect, and achieve the effect of reasonable structure and water saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

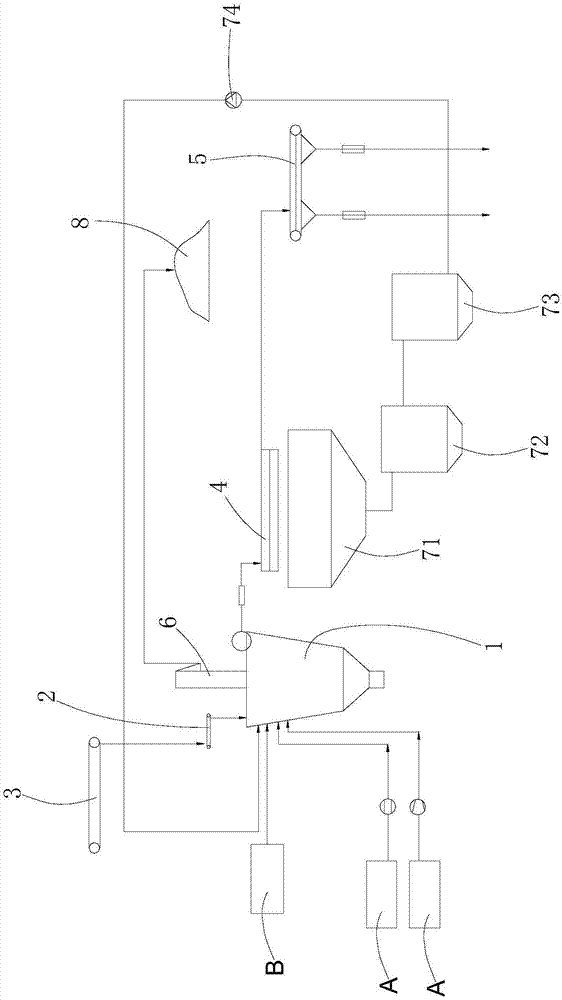

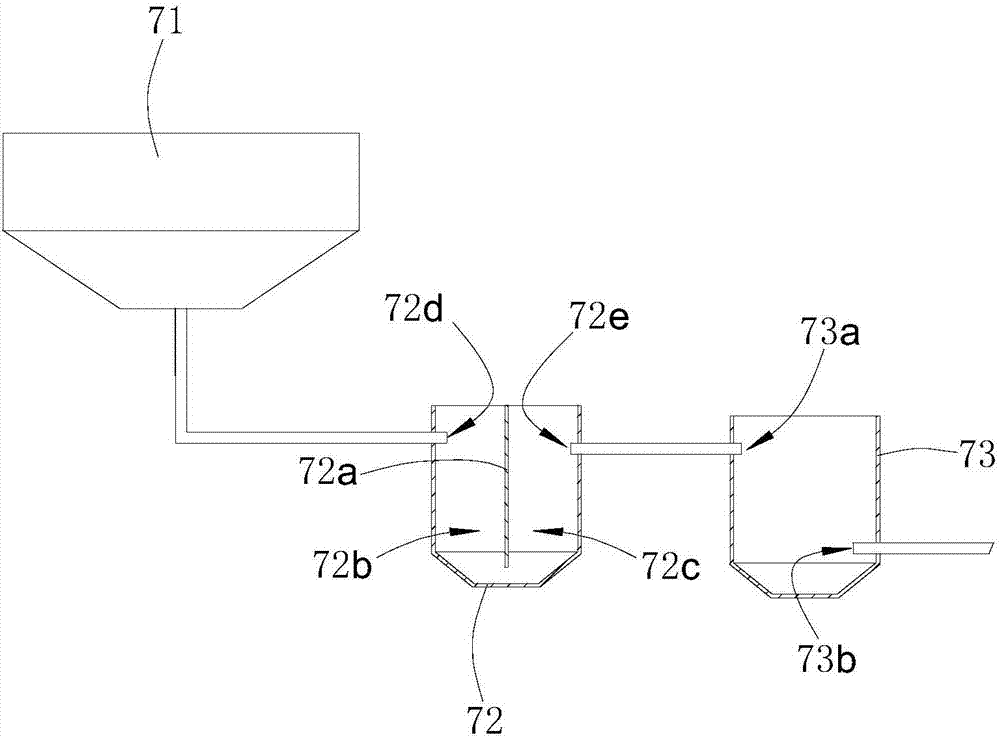

[0022] Such as Figures 1 to 2 shown

[0023] The corn water washing and impurity removal device includes a discharge conveyor belt 3, a corn jig 1, a distributor 2, a grading dewatering screen 4, a fine material scraper machine 5, a tubular elevator 6, and a water circulation component.

[0024] The upper and lower ends of the trough of the corn jig 1 are open, and the area of the upper opening is much larger than the area of the lower opening. The corn jig 1 is provided with two air source interfaces and two water source interfaces, and the two air source interfaces are respectively connected to the external The high-pressure or normal-pressure air sources are connected. The two air source interfaces are responsible for introducing the external air A into the material trough of the corn jig machine 1. The two water source interfaces are the external water source interface and the circulating water source interface. The external water source interface connects the externa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com