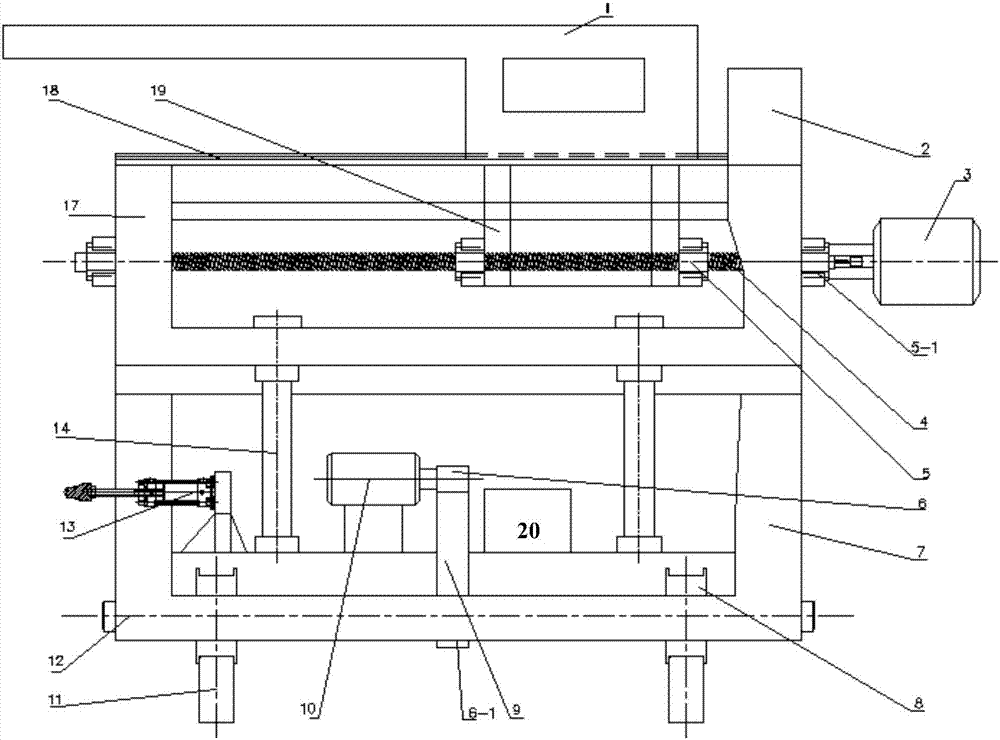

Device and method for double-forklift forging die transferring, loading and unloading

A die and double car technology, applied in forging/pressing/hammer devices, manufacturing tools, forging/pressing/hammering machinery, etc., can solve the problems of time-consuming and laborious forging, inaccurate positioning, and heavy forging die.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

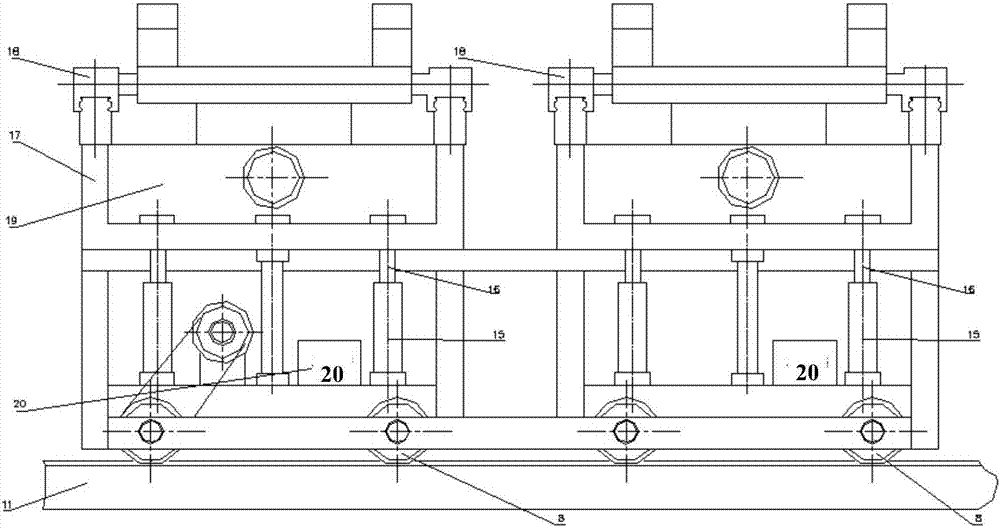

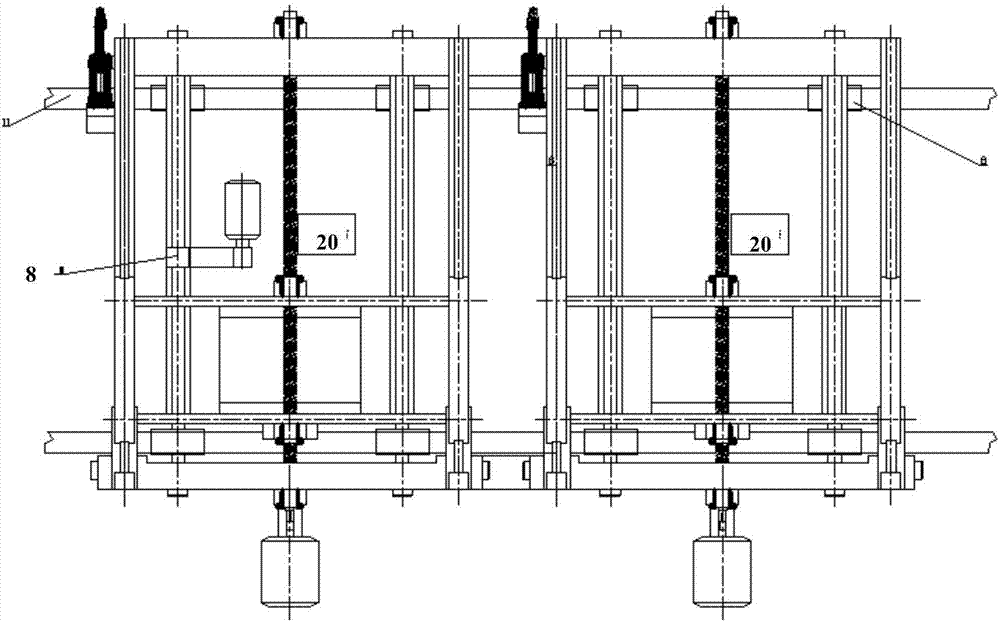

[0020] Step 1: When the forging mold is placed on the mold platform, the manual switch is turned on and the servo motor A (3) is controlled by the PLC system to drive the guide screw (4) to rotate through the coupling. Through the rotation of the guide screw (4), the mold drag bar lower frame (19) drives the mold drag bar (1) to move left on the linear guide rail (18) and insert it into the mold slot, and the piston rod of the hydraulic cylinder (14) is under the action of external mesons Lift the lower frame (17) of the linear guide rail through the guidance of the guide sleeve (15) and the guide rod (16) to lift the mold, and the manual switch is turned on. The servo motor A (3) is controlled by the PLC system to drive the guide screw through the coupling. (4) back spin. Drive the mold drag bar (1) to move the mold to the right on the linear guide rail (18) and place it above the device by the guide screw (4) rerotating the lower frame of the mold drag bar (19).

[0021] St...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com