Machine-spray dry-blending plastering mortar

A technology for plastering mortar and machine-made sand, applied in the field of dry-mix plastering mortar, can solve the problems of grading and breaking, no grading concept, affecting construction quality, etc., to reduce production costs, reduce cement consumption, and achieve reasonable grading. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

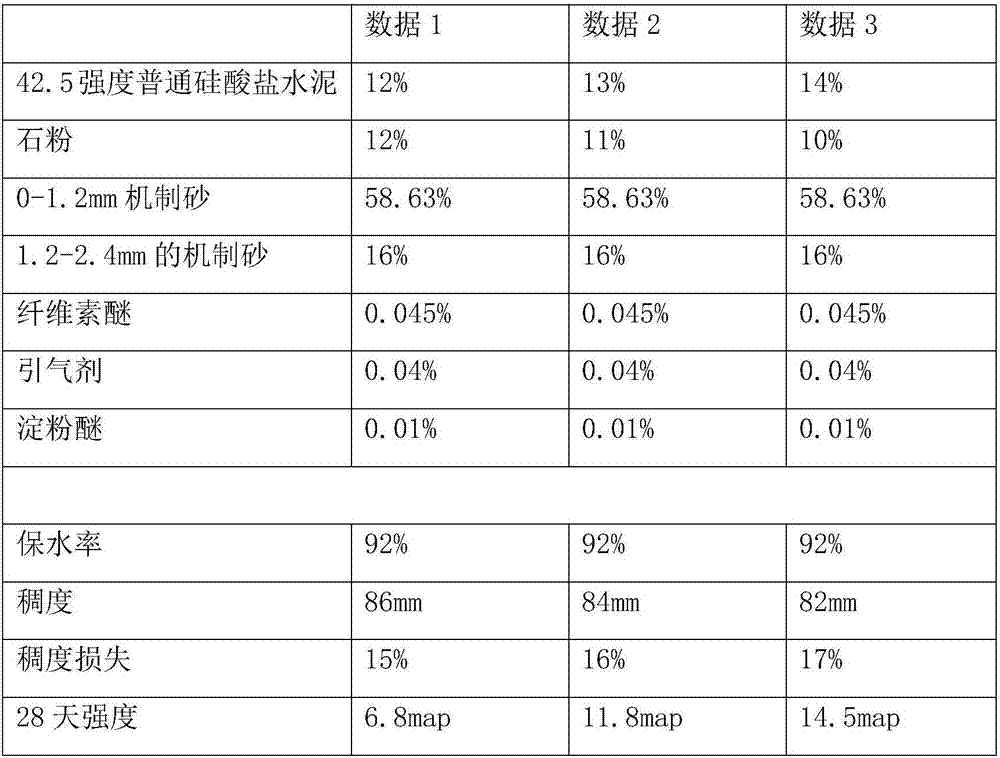

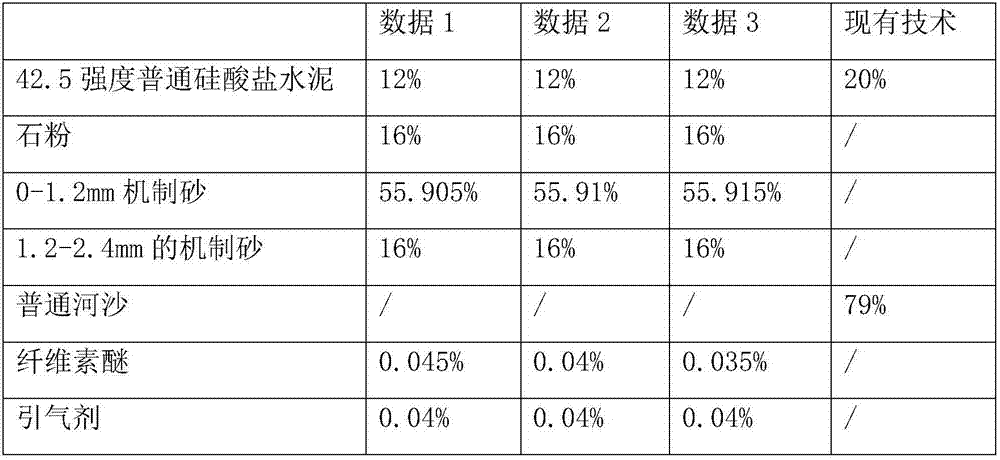

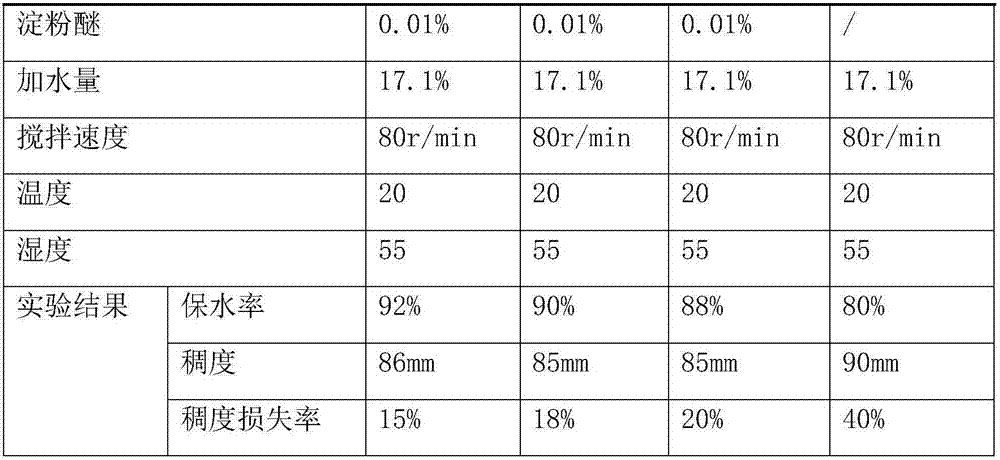

[0027] A machine-sprayed dry-mixed plastering mortar, comprising main raw materials and additives. The main raw materials are composed of 12%-14% 42.5-strength ordinary Portland cement, 16%-24% stone powder, 56%-66 % medium sand of machine-made sand and 0-16% coarse sand of machine-made sand; its additives include 0.03%-0.055% cellulose ether, 0.005%-0.015% starch ether and 0.02%-0.05% air-entraining agent; the rest is water.

[0028] Among them, the particle size range of sand in machine-made sand includes: 0-0.075mm: 9%, 0.075-0.15mm: 7.5%, 0.15-0.3mm: 10.5%, 0.3-0.6mm: 23.5%, 0.6-1.2mm: 33.5% %, 1.2-2.4mm: 16%; the particle size of machine-made sand coarse sand includes: 0.6-1.2mm: 2%, 1.2-2.4mm: 81%, 2.4-4.75mm: 17%.

[0029] The ratio content of the particle size of the above-mentioned machine-made sand will not be interrupted during the grading process of the machine-made sand, so that the occlusion of each particle size can reach the highest level, and the phenomenon of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com