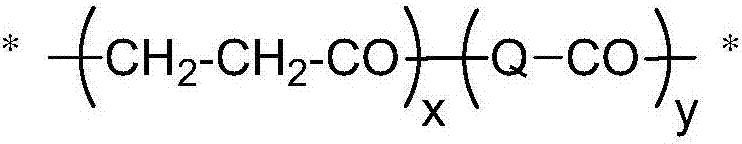

Polyketone moulding compounds with improved properties, moulded articles produced therefrom and also method for the production thereof

A molding compound, polyketone technology, applied in the field of polyketone molding compound, can solve the problems of high melting, thermal and mechanical properties damage, no protection against volatile compounds, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

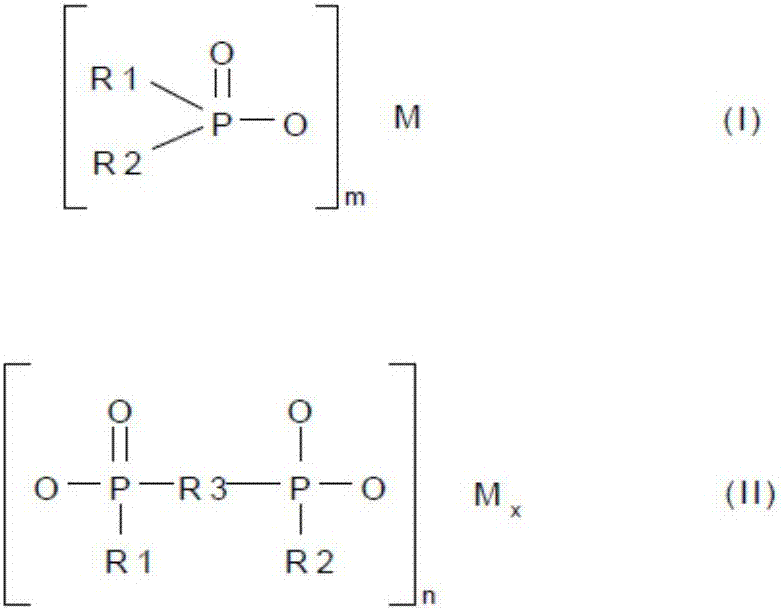

Method used

Image

Examples

preparation example Construction

[0125] Preparation of polyketone molding compound

[0126] The raw materials of components (A), (C) and (D) were premixed and metered by weight into the feed of a twin-screw extruder of type ZSK25 (Werner and Pfleiderer). Component (B) was metered into the melt via a side feeder 4 housing unit ahead of the discharge. The process is carried out at a barrel temperature of 200° C. to 270° C. with a screw speed of 200 rpm and a throughput of 10 kg / h. The material is discharged through nozzles and pelletized after cooling the stream. Drying was then carried out in vacuo at 100° C. for 24 hours.

[0127] Manufacture of molded articles

[0128] The manufacture of the molded articles was carried out on an injection molding machine Arburg Allrounder 420C-1000-250 with a barrel temperature ramp of 200°C to 270°C and an injection pressure of 1000 bar to 1800 bar. The mold temperature was 80°C. The geometry of the molded articles corresponds to the specifications of the respectiv...

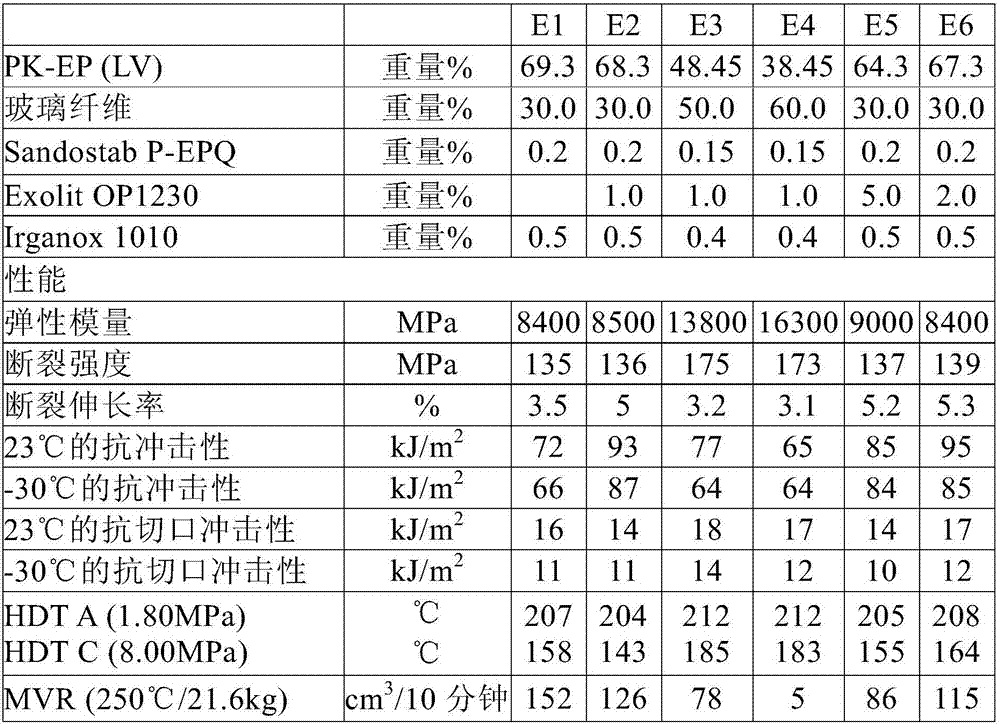

Embodiment E1-E6

[0141]

[0142] % by weight = percent by weight

[0143] Table 2: Comparative Examples CE1-CE7

[0144]

[0145] % by weight = percent by weight

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Mfr | aaaaa | aaaaa |

| Mfr | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com