Technical application of fractionation crystallizing tank for rapeseed oil dewaxing process

A technology of crystallization tank and rapeseed oil, applied in the direction of fat oil/fat refining, fat production, etc., can solve the problem that the winterization production capacity cannot meet the needs of business delivery and packaging oil, and improve the effective utilization rate, improve the effect, Improve oil-boosting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

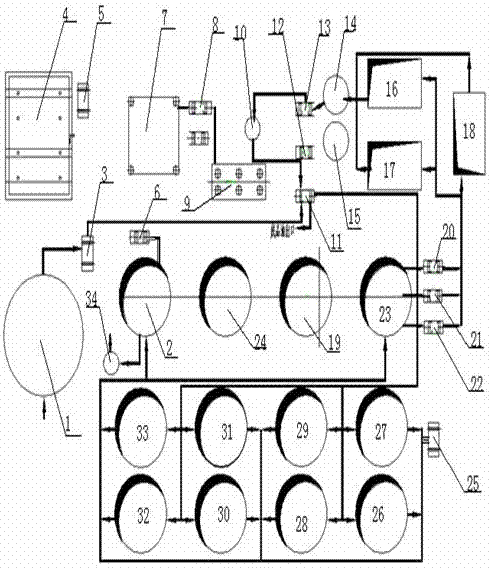

[0012] A fractionation and crystallization tank is used for the technical application of rapeseed oil dewaxing process, such as figure 1 As shown, a two-stage process of crystallization process and filter aid process is adopted. The crystallization process adopts the gradual cooling method of 8 crystallization tanks in the fractionation system, the oil temperature is controlled at 10-14 ° C, and the frequency of the crystallization tank is 20-45HZ; In the filter aid process, after the crystallization of rapeseed oil is completed, filter aid is added to filter out the refined oil. The oil outlet temperature of the refined oil is 10-25°C, the water content is ≤0.02%, the wax content is ≤5ppm, and the freezing time is more than 24 hours.

[0013] The crystallization process is to drive the first-grade oil in the crude oil tank 1 into the energy-saving heat exchanger 11 through the crude oil pump 3, enter the crystallization tank of the fractionation system after heat exchange, pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com