Ultrasonic washing machine and clothes washing method thereof

A washing machine, ultrasonic technology, applied in other washing machines, oscillating washing machines, washing devices, etc., can solve the problems of polluted environment, incomplete sterilization, high sterilization cost, etc., to kill germs, avoid secondary pollution, remove stains and mold Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

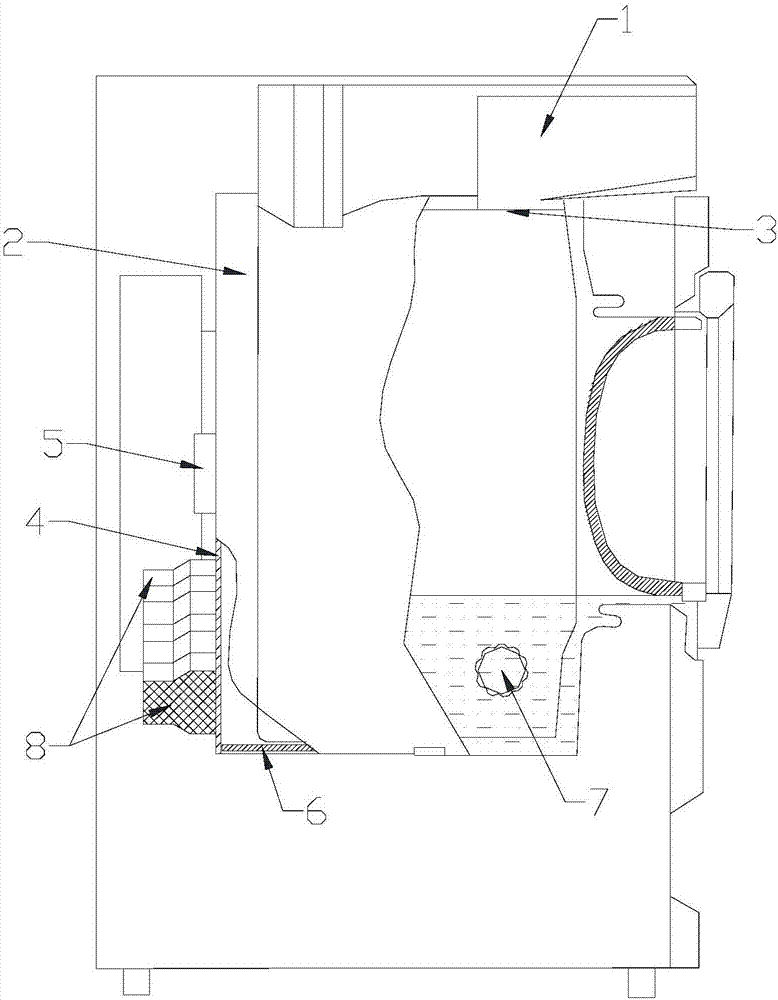

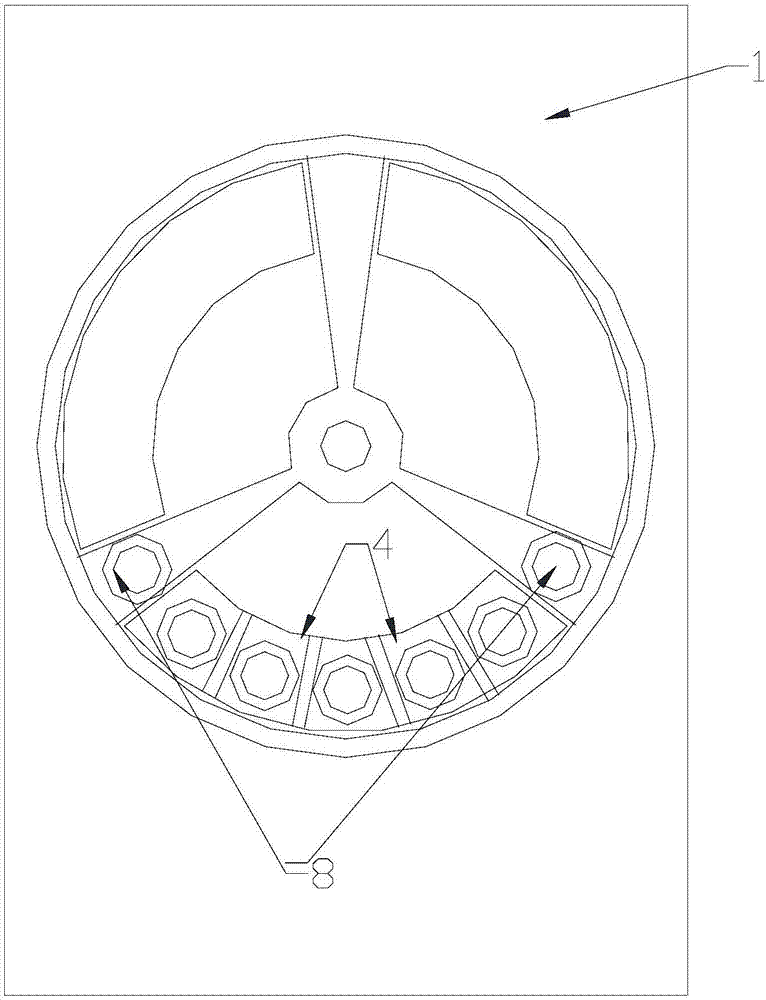

[0025] like figure 1 and 2 As shown, the ultrasonic washing machine includes a washing machine body 1 , an ultrasonic generator 5 , a heating pipe 6 , seven vibrating plates 4 and seven ultrasonic transducers 8 . The ultrasonic washing machine of the present invention can simultaneously realize the functions of automatic cleaning of the washing machine and washing and sterilization of clothes, and has the advantages of low sterilization cost, thorough sterilization and washing, and little environmental pollution.

[0026] The ultrasonic generator 5 is connected with seven ultrasonic transducers 8 respectively, and the input power of the washing machine body 1 is connected with the ultrasonic generator 5 and the heating pipe 6 respectively. The ultrasonic generator 5 is used to convert the alternating current with a voltage of 220V and a frequency of 50 Hz into a high-frequency alternating current signal matched with the ultrasonic transducer 8 and send it to the ultrasonic tr...

Embodiment 2

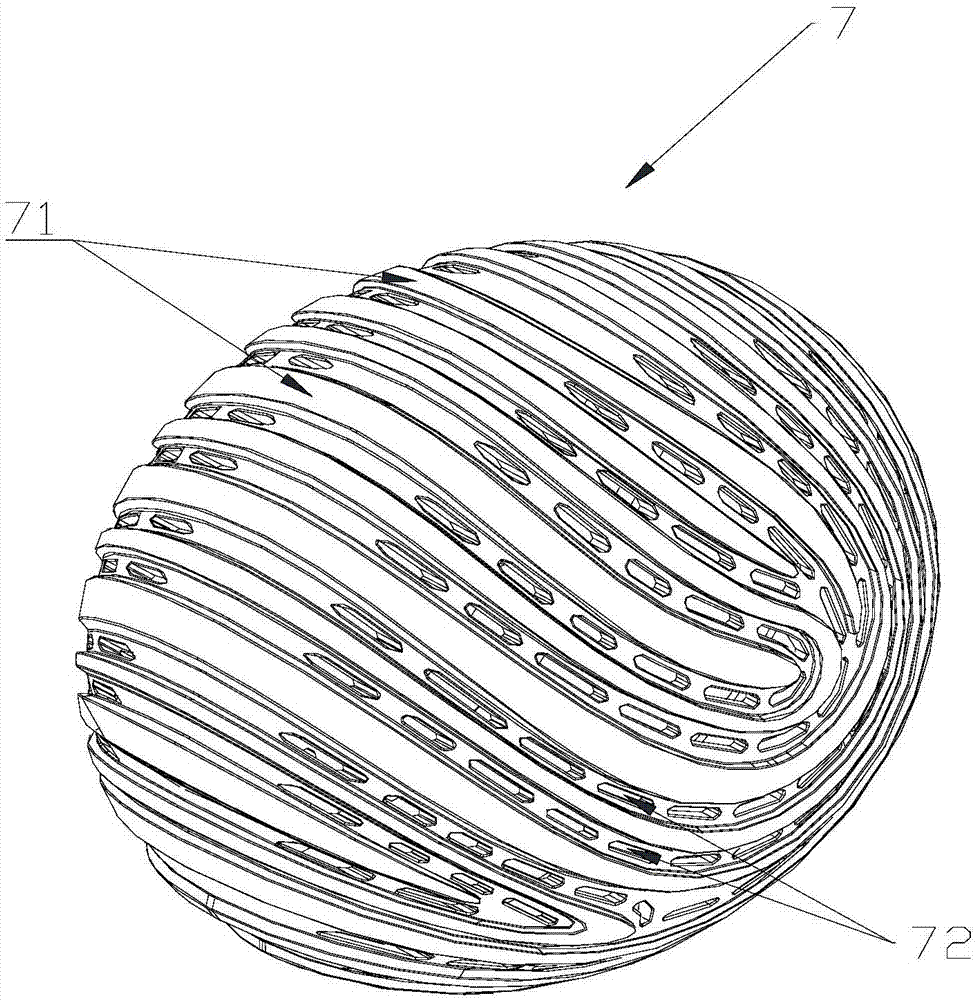

[0040] like Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that the washing machine body in this embodiment is a multifunctional washing machine, the ultrasonic generator 5 is installed on the outer surface of the bottom plate of the water tub 2, and the edge of the bottom plate of the water tub 2 One first window is provided, and two second windows are arranged on the lower part of the side plate of the bucket 2, and the two second windows are arranged symmetrically. The first vibrating plate 41 is fixed on the bottom plate of the tub 2 by screws and covers the first window, and the first vibrating plate 41 matches the shape of the first window. The two second vibrating plates 42 are respectively fixed on the side plates of the tub by screws and cover the two second windows. A plurality of ultrasonic transducers 8 are fixedly mounted on the second surface of each vibrating plate 4 by screws. The heating pipe 6 is installed at the bottom of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com