Down-horizontal-type sluice gate

A gate and gate pier technology, which is applied in the field of lowering and horizontal gates, can solve the problems of low water temperature, large operating force, unsuitable for water diversion requirements in irrigation areas, etc., and achieves the effect of reducing the introduction amount, reducing the power intensity, and being conducive to stable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

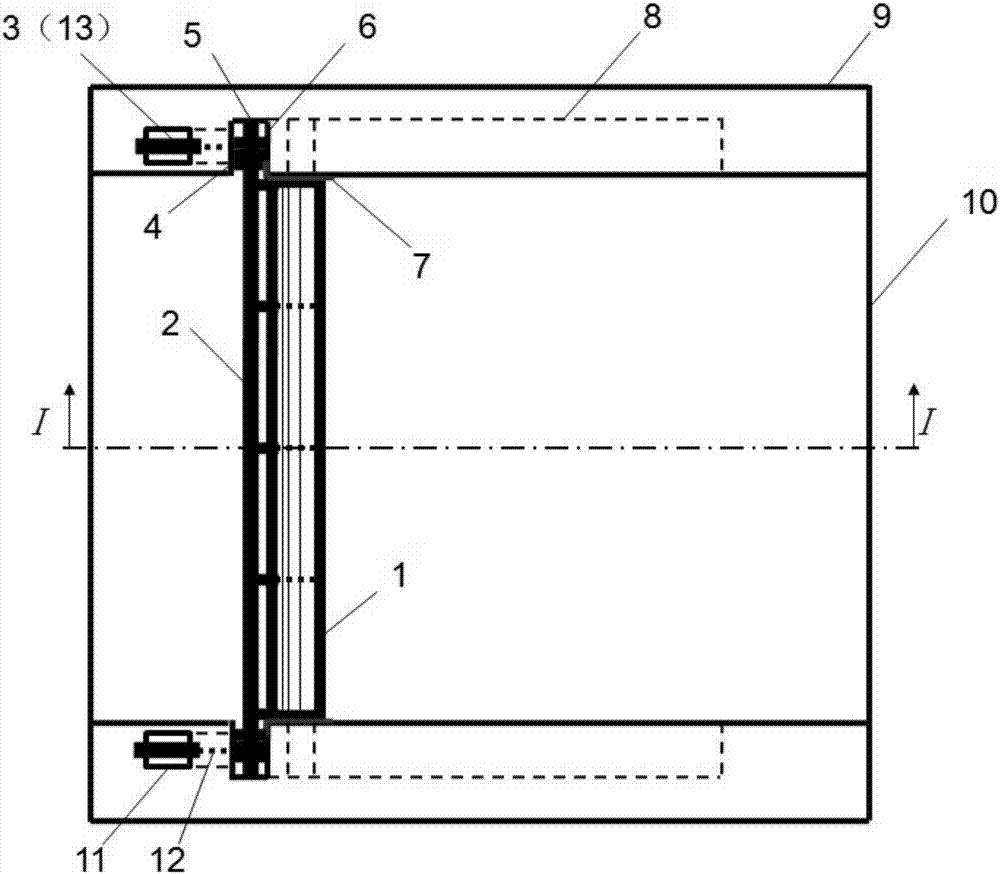

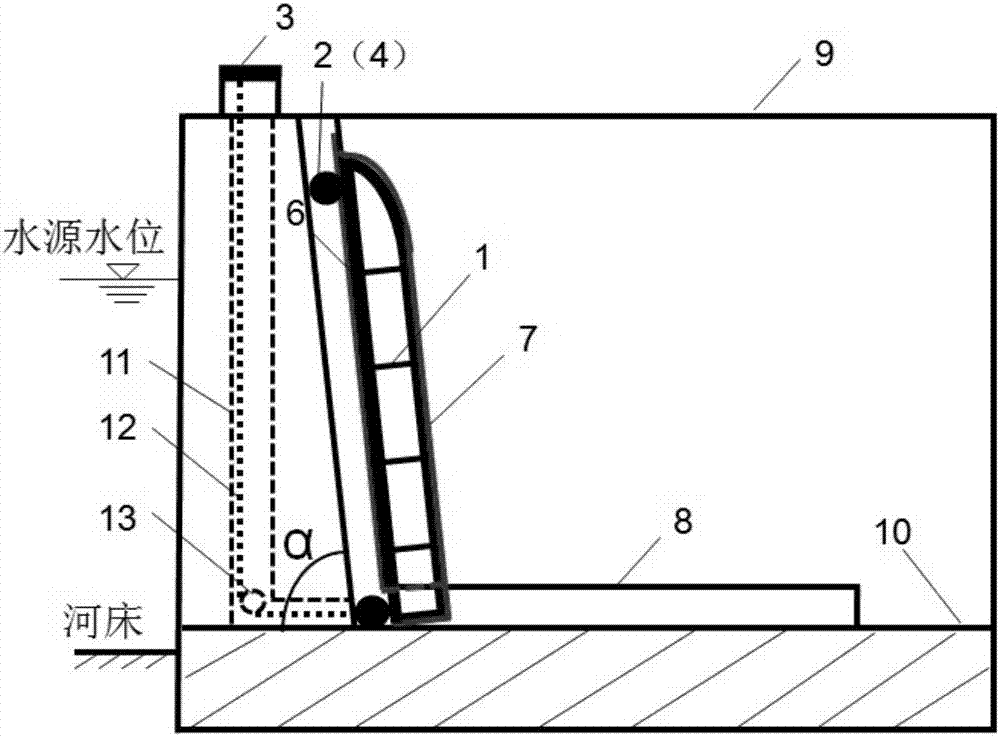

[0018] Gate pier 9 and gate bottom plate 10 are concrete structures, reinforced concrete structures, or masonry structures, etc., depending on the depth of the upstream water; gate piers 9 and gate bottom plates 10 on both sides are poured on site and formed into a complete overall structure , to increase its stability; the elevation of the gate pier 9 pier top should be greater than a certain height of the upstream water level, based on ensuring safe operation; the gate 1 is made of steel or alloy materials, which should have sufficient rigidity and strength, and anti-rust treatment should be done. The gate 1 is provided with a longitudinal partition and a transverse partition to increase the strength and rigidity of the gate.

[0019] A water stop 7 is provided between the gate 1 and the gate pier 9 and between the gate bottom plate 10 to prevent the gate 1 from leaking.

[0020] The opening and closing of the gate 1 is controlled by a hoist to meet the control of the gate 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com