Solidification treatment method of mucky soil

A solidification treatment, silty soil technology, applied in soil protection, construction, infrastructure engineering, etc., can solve the problems of solidification reaction into biodestruction, large soil structure damage, strong cation exchange capacity, etc., to achieve good economy And strength benefits, high early strength, good frost resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

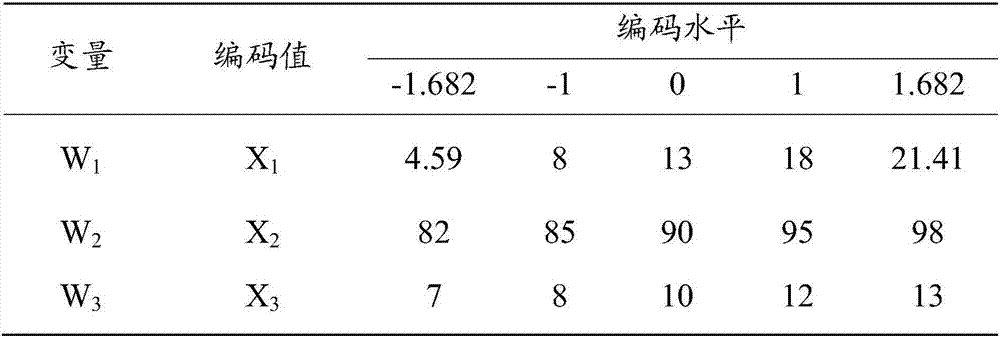

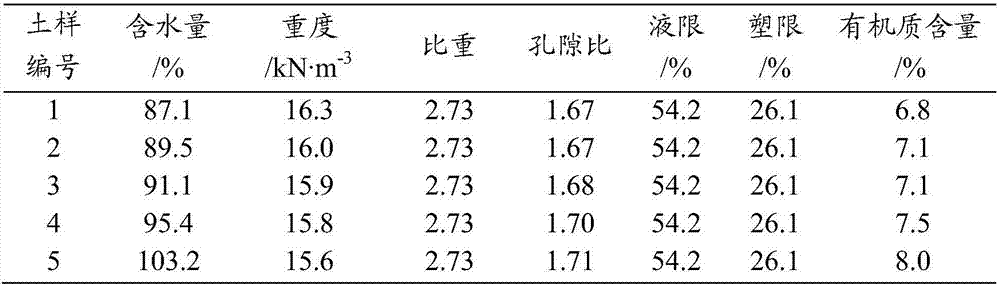

Method used

Image

Examples

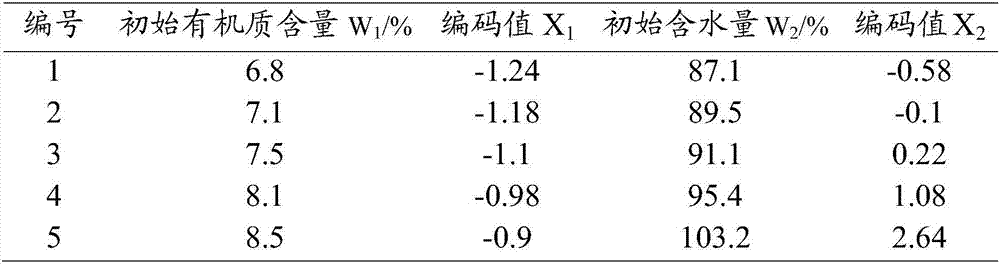

Embodiment 1

[0042] Take the silty soil sample numbered 1, before the test, remove the impurities in the soil sample, weigh 600g of the soil sample, and bring it into the formula (1) according to the converted code value in Table 3, and the formula (1) is simplified as Y= 1290.77+124.72X 3 +9.92X 3 2 Add different amounts of curing agent according to the proportioning ratio (the weight percentage of each component is: cement 46%, slag 34%, fly ash 15%, triethanolamine 5%), when the curing agent dosage changes from 6% to 12% , stir the mixture well to make 3 Parallel cylinder specimens, standard curing 28 days. The strength values of the solidified soil are shown in Table 4:

[0043] Table 4 Comparison of predicted strength of soil sample 1 quantitative model and measured strength

[0044]

[0045]

Embodiment 2

[0047] Take the silty soil sample numbered 2, before the test, remove the impurities in the soil sample, weigh 600g of the soil sample, and bring it into the formula (1) according to the converted code value in Table 3, and the formula (1) is simplified as Y= 1270.48+122.26X 3 +9.92X 3 2 Add different amounts of curing agent according to the proportioning ratio (the weight percentage of each component is: cement 46%, slag 34%, fly ash 15%, triethanolamine 5%), when the curing agent dosage changes from 6% to 12% , stir the mixture well to make 3 Parallel cylinder specimens, standard curing 28 days. The strength values of the solidified soil are shown in Table 5:

[0048] Table 5 Comparison of predicted strength of soil sample 2 quantitative model and measured strength

[0049]

Embodiment 3

[0051] Take the silty soil sample numbered 3, before the test, remove the impurities in the soil sample, weigh 600g of the soil sample, and bring it into the formula (1) according to the converted code value in Table 3, and the formula (1) is simplified as Y= 1236.57+118.96X 3 +9.92X 3 2 Add different amounts of curing agent according to the proportioning ratio (the weight percentage of each component is: cement 46%, slag 34%, fly ash 15%, triethanolamine 5%), when the curing agent dosage changes from 6% to 12% , stir the mixture well to make 3 Parallel cylinder specimens, standard curing 28 days. The strength values of the solidified soil are shown in Table 6:

[0052] Table 6 Comparison of predicted strength of soil sample 3 with quantitative model and measured strength

[0053]

[0054]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com