Smoke exhaust structure for anti-freezing gas engine

A technology of gas engine and smoke exhaust pipe, which is applied in the direction of combustion method, exhaust gas device, combustion product treatment, etc., can solve the problem of low energy utilization rate of antifreeze gas engine, achieve low transformation cost, improve thermal efficiency, and energy utilization high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

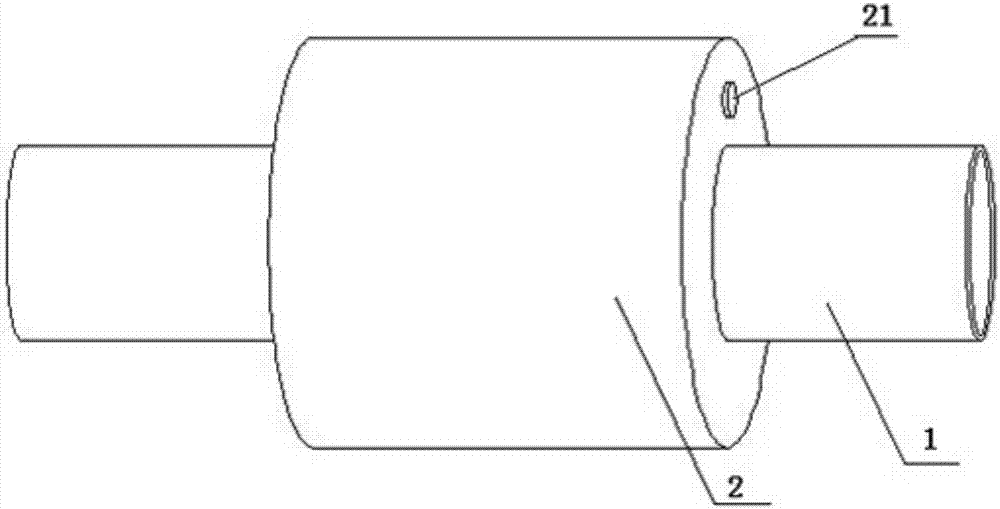

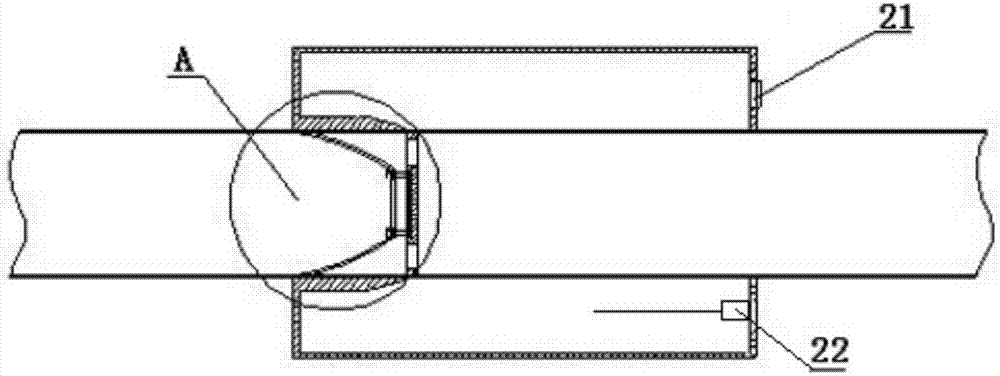

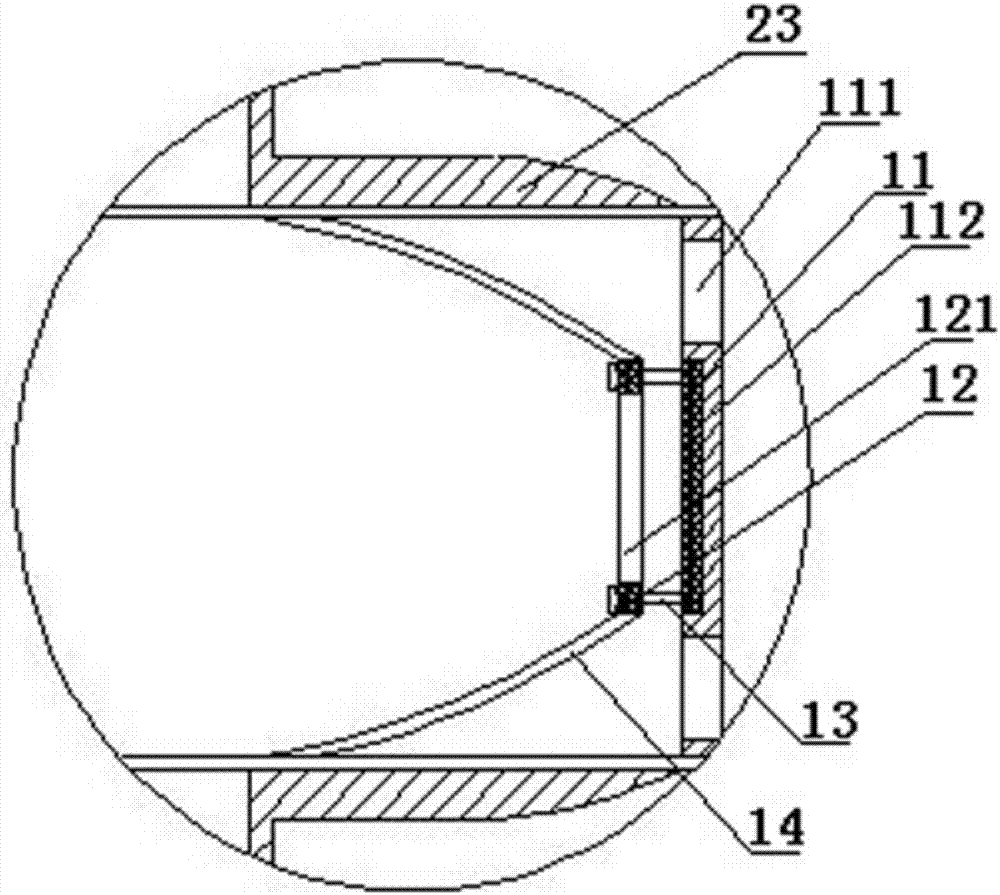

[0018] Such as Figure 1-Figure 3 As shown, a smoke exhaust structure of an antifreeze gas engine includes a smoke exhaust pipe 1 and a fan connected to each other. The inside of the smoke exhaust pipe 1 is provided with a circular fixing plate 11 with the same diameter as the smoke exhaust pipe 1. The central axis of the smoke exhaust pipe 1 of the fixed plate 11 coincides, the central position of the fixed plate 11 is inlaid with a fixed magnetic plate 112, and the fixed plate 11 is provided with some fixed smoke outlet holes 111 near the edge position; There is a non-elastic connection bag 14 sealingly connected to the inner wall of the smoke exhaust pipe 1. The non-elastic connection bag 14 is provided with a movable magnetic plate 12 parallel and coaxial with the fixed plate 11. The center of the movable magnetic plate 12 is provided with Active smoke hole 121.

[0019] In this embodiment, a guide rod 13 is provided between the movable magnetic plate 12 and the fixed pla...

Embodiment 2

[0023] On the basis of the smoke exhaust structure of an antifreeze gas engine described in Example 1, it is further optimized. The outer sealing sleeve of the smoke exhaust pipe 1 is provided with a heat preservation sleeve 2, and the heat preservation sleeve 2 and the smoke exhaust pipe 1 A thermal insulation cavity is formed, and a water injection port 21 connected to the thermal insulation cavity is provided on the thermal insulation sleeve 2. A temperature control electric heating device 22 is provided inside the thermal insulation cavity, and an insulation layer is provided on the side of the thermal insulation cavity close to the movable magnetic plate 12. twenty three.

[0024] This embodiment mainly relies on the relatively large specific heat capacity of water, which can store heat, and makes full use of the waste heat of flue gas to heat the water in the heat preservation cavity to store energy, maintain the temperature of the part connected to the exhaust pipe 1 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com