Oil and gas pipeline online stress ultrasonic measuring device

A technology for oil and gas pipelines and ultrasonic measurement, which is used in measurement devices, force/torque/power measuring instruments, instruments, etc., and can solve the problems of time measurement accuracy can only be reached, ultrasonic measurement stress device is large, sampling frequency is difficult, etc. Easy and flexible disassembly and assembly, the effect of preventing electromagnetic interference and reducing complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

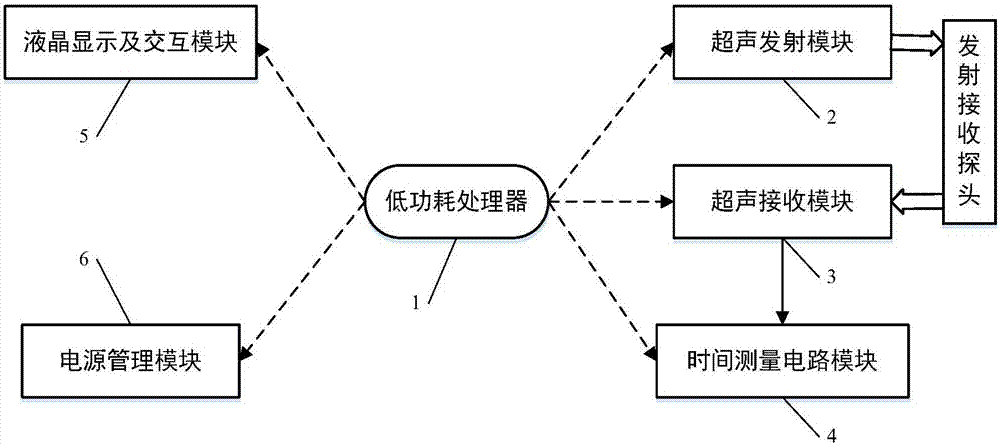

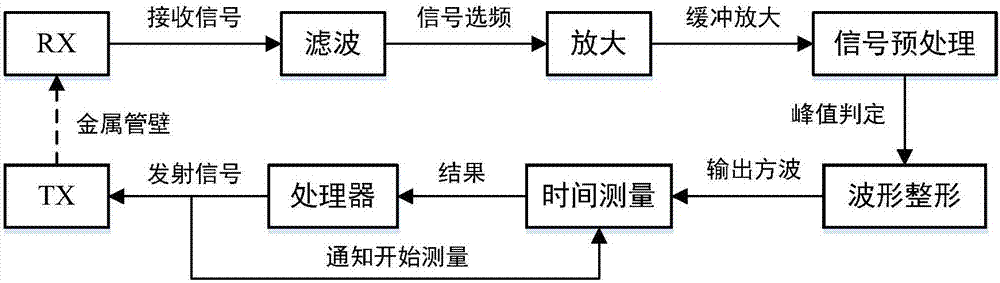

[0025] Such as figure 1 As shown, the online stress ultrasonic measurement device for oil and gas pipelines includes: a low-power processor 1, an ultrasonic transmitting module 2, an ultrasonic receiving module 3, a time measurement circuit module 4, a liquid crystal display and interactive module 5, and a power management module 6; where: The ultrasonic transmitting module is used to transmit high-voltage pulses; the ultrasonic receiving module is mainly used to amplify and shape the waveform of the received signal; the time measurement circuit module is used to measure the time interval between the ultrasonic transmission start signal (START signal) and stop signal (STOP signal) The liquid crystal display and interactive module is used for system management and measurement result display; the power management module is used for low power co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com