Slickwater fracturing fluid friction testing device and testing method thereof

A testing device and hydraulic fracturing technology, applied in the field of instrumentation, can solve the problems of difficult high pressure, no type given, difficult maintenance, etc., and achieve the effect of convenient testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

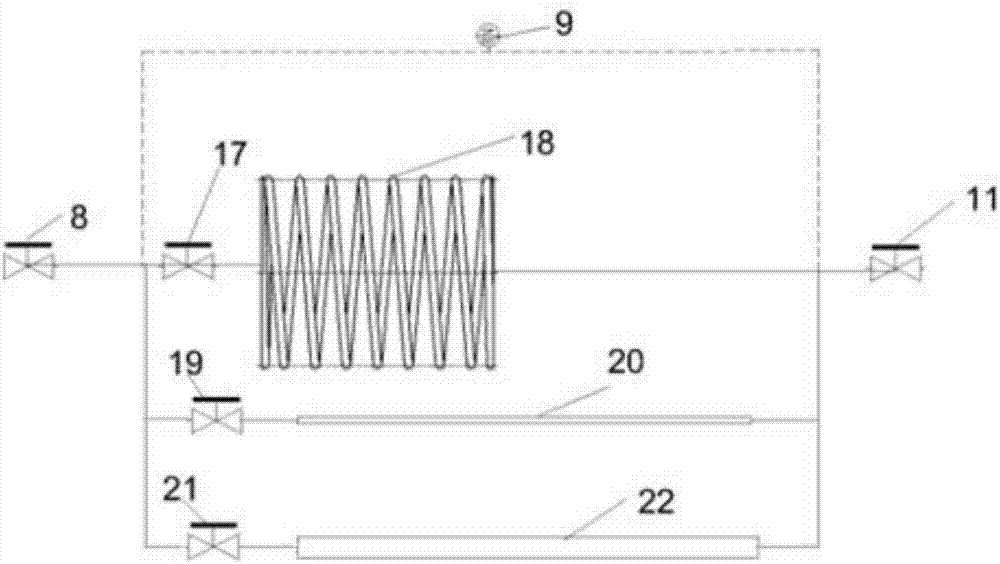

[0036] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

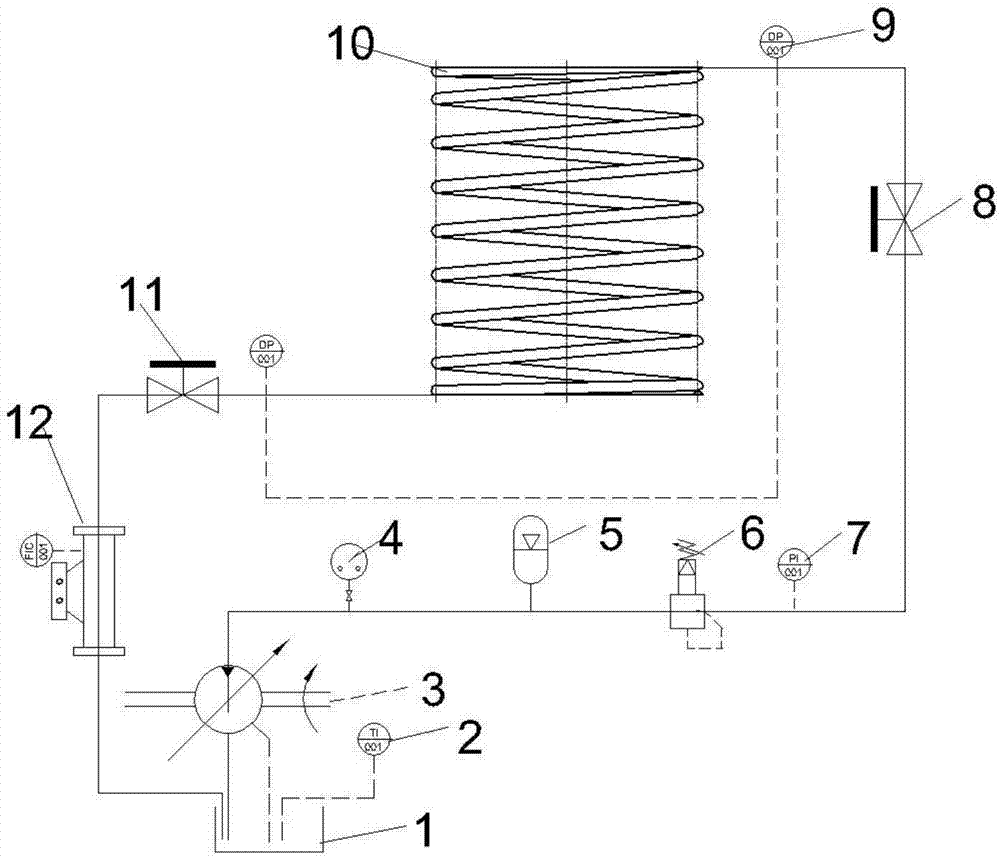

[0037] Such as figure 1 As shown, check the equipment before the experiment, then inject a slick water fracturing fluid without drag reducer into the liquid tank 1 and select relevant branches for friction and pressure drop tests, and then configure different ratios in advance. Friction pressure drop test for slick water fracturing fluid as drag reducer.

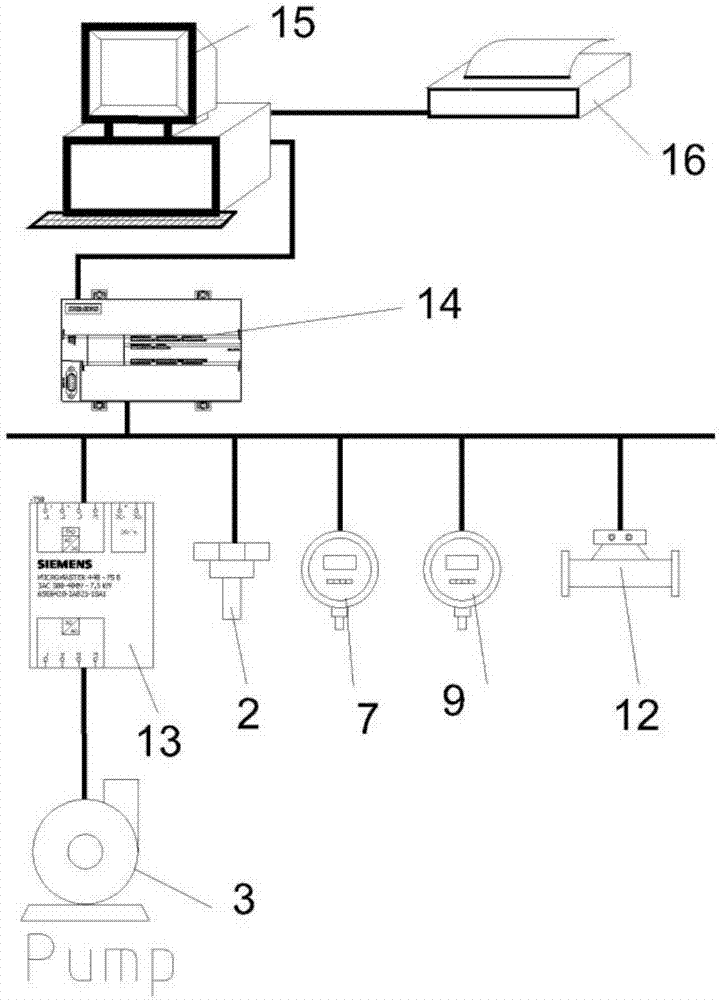

[0038] The test circulation pipeline mainly includes liquid medicine tank 1, temperature transmitter 2, liquid medicine pump 3, electric contact pressure gauge 4, pulse damper 5, pressure reducing valve 6, pressure transmitter 7, first valve 8, Differential pressure transmitter 9, test pipeline system 10, second valve 11, flow meter 12 and pipelines connecting various components, etc.

[0039] The airbag-type pulse damper adopted in the present invention c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com