Auxiliary device for controlling programming

A technology of auxiliary equipment and physical control, applied in the direction of program control, comprehensive factory control, program control in sequence/logic controller, etc., can solve the problems of high labor intensity, time-consuming and complicated operation of operators, and achieve Save debugging time, improve work efficiency, and have a simple structural framework

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0038] In order to achieve the purpose of the present invention, in some embodiments of a control programming auxiliary device, a control programming auxiliary device is developed based on a programmable logic controller PLC and CAD. Programmable logic controller PLC is a kind of programmable memory, which is used to store programs internally, execute logic operations, sequence control, timing, counting and arithmetic operations and other user-oriented instructions, and through digital or analog input / Output controls various types of machinery or production processes. Computer Aided Design (CAD) refers to the use of computers and graphics equipment to help designers in their design work.

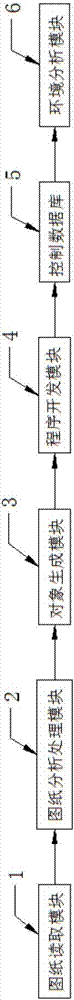

[0039] Such as figure 1 As shown, a control programming auxiliary device includes: drawing reading module 1, drawing analysis and processing module 2, o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com