Exponent regularization and null space linearity discriminant analysis-based fault diagnosis method

A linear differential analysis and fault diagnosis technology, applied in the direction of instruments, electrical testing/monitoring, control/regulation systems, etc., can solve problems such as blindness, unsupervised, and limited ability to solve singular matrices, and achieve accurate identification and improve accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

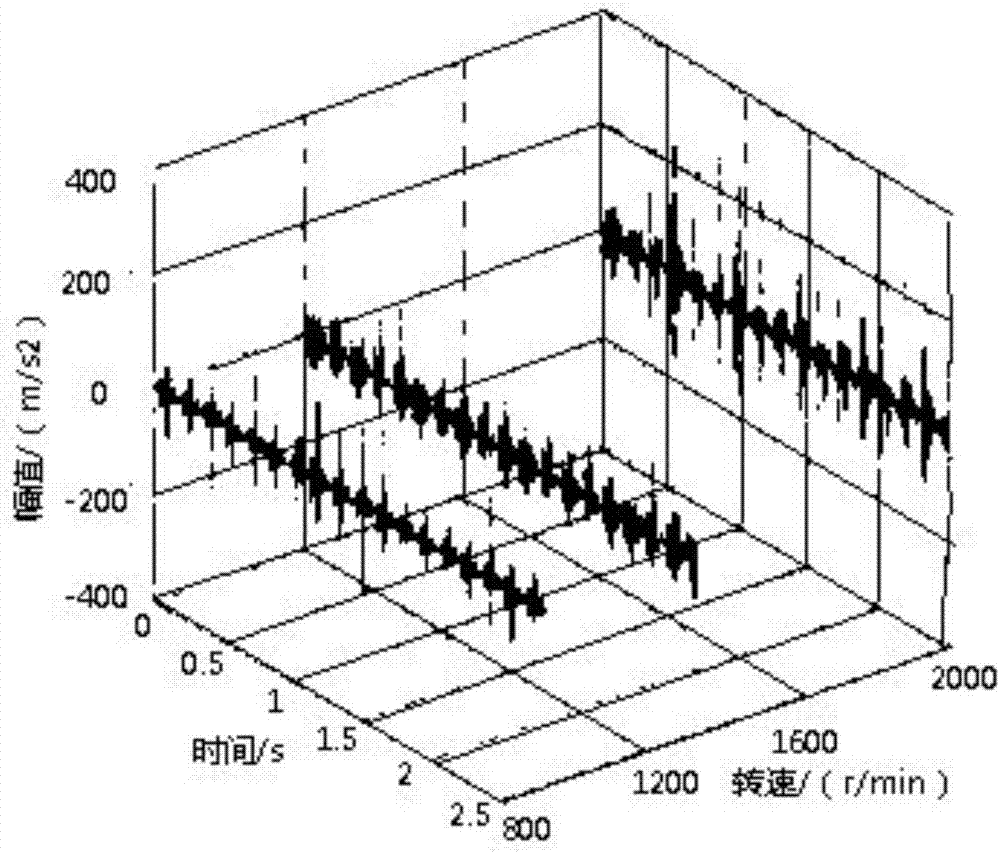

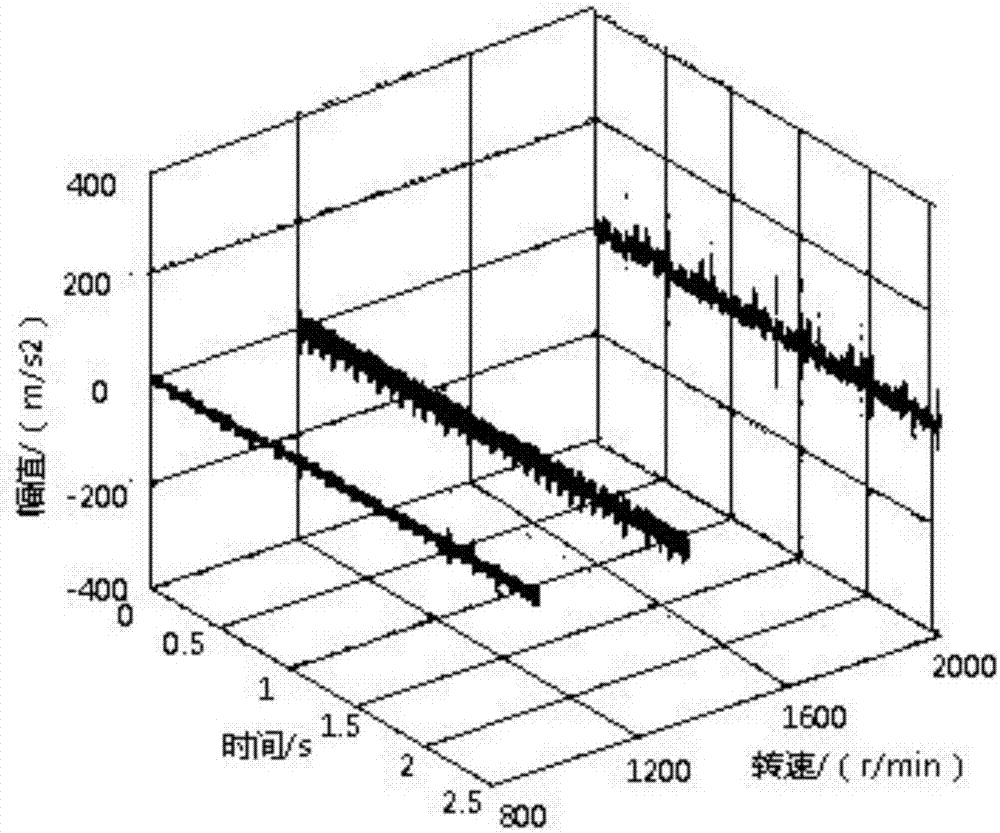

[0063] Engine AVL simulation model: it can simulate four states of engine normal state, one-cylinder misfire failure, one-two cylinder misfire and one-four cylinder misfire failure. In each state, three speeds of 800r / min, 1200r / min and 2000r / min are designed respectively. In the experiment, the vibration signals of four types of faults in each speed state were extracted, a total of 12 groups of vibration signals, the sampling time was 10 seconds, and the number of sampling points was 57000.

[0064] For the engine, the vibration signal of the cylinder head contains rich information, which can effectively reflect changes in the speed, cylinder pressure and piston impact, so the use of it for engine fault diagnosis and status monitoring has high universality and easy signal acquisition. In this experiment, by studying the changes of the engine vibration signal, extracting the corresponding time-domain features and frequency-domain features, combined with the ERNSLDA algorithm p...

Embodiment 2

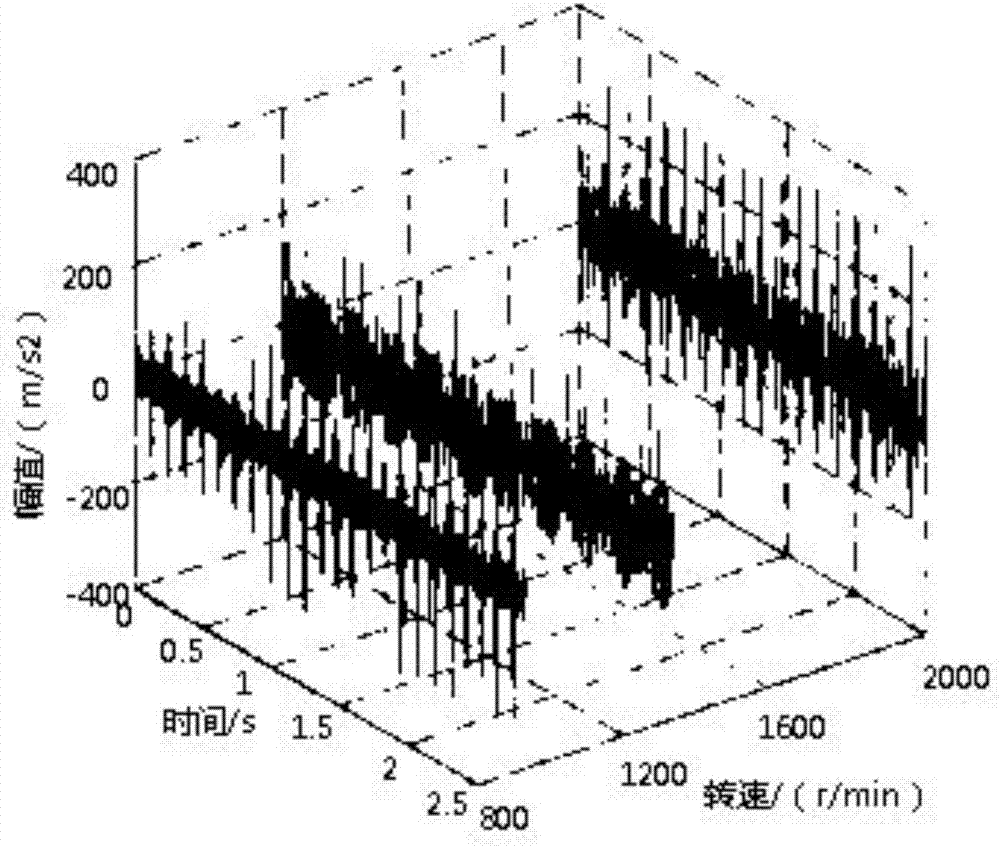

[0070] Gearbox fault simulation: The gearbox fault simulation test bench mainly simulates five states of bearing outer ring fault, inner ring fault, rolling element fault, gear tooth surface loss and broken tooth fault, respectively recorded as (f1, f2, f3, f4, f5), where the number of gears at the input end is 55, the number of gears at the output end is 75, and the modulus is 2. The vibration signal is collected by the vibration acceleration sensor. During the signal collection process, the motor speed is set to 1200r / min, and the sampling frequency is 10KHz. 20 groups of vibration signals in each of the 5 states are collected, totaling 100 groups of vibration signals.

[0071] The time domain, frequency domain and time-frequency domain signal features are extracted from the original vibration signal to form a corresponding high-dimensional fault feature set. The ERNSLDA algorithm proposed in this paper is used to classify and identify the fault state of the gearbox, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com