Low-seepage compact sandstone reservoir fluid saturation degree correction method

A technology for tight sandstone reservoirs and calibration methods, which is applied in the fields of earthwork drilling, special data processing applications, instruments, etc., can solve the problems of only considering a single factor, complicated operations, and low calibration accuracy, and achieves strong operability and improved performance. Correction accuracy and effect of improving correlation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with embodiment and accompanying drawing

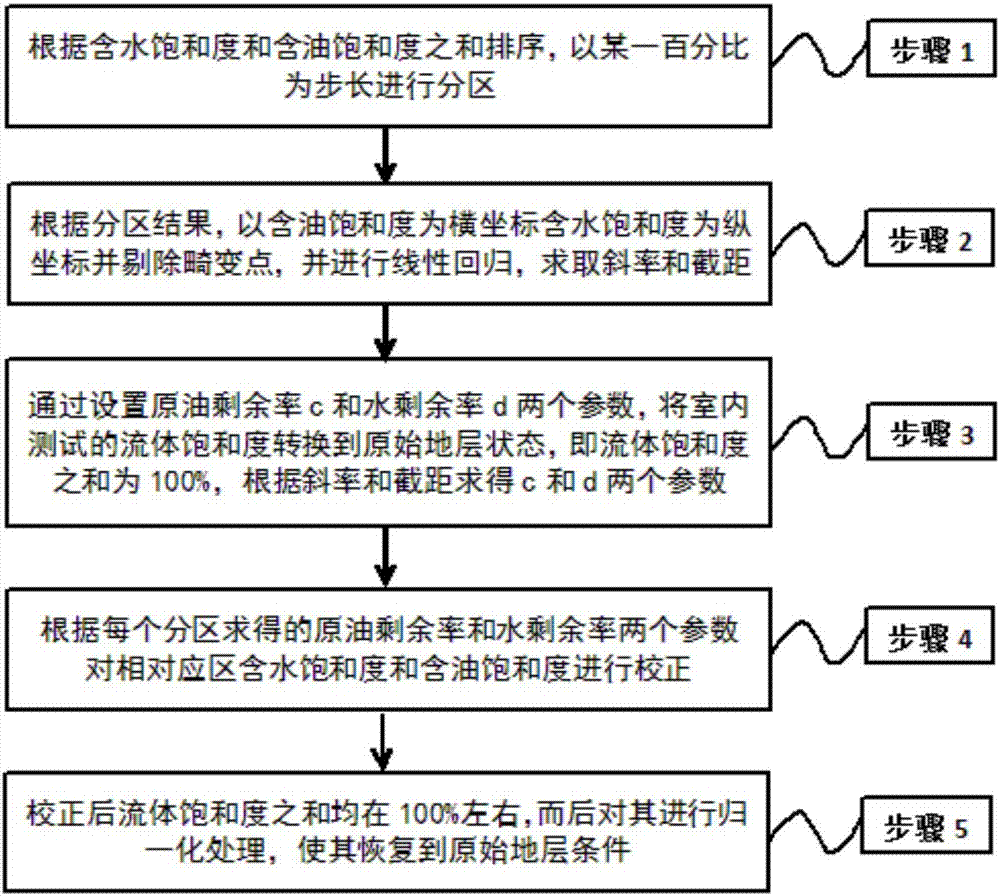

[0029] like figure 1 As shown, the low-permeability tight sandstone reservoir fluid saturation correction method of the present invention comprises the following steps:

[0030] The first step is to sort according to the sum of water saturation and oil saturation, and partition with a step size of 5%. The partition results are shown in the table below;

[0031]

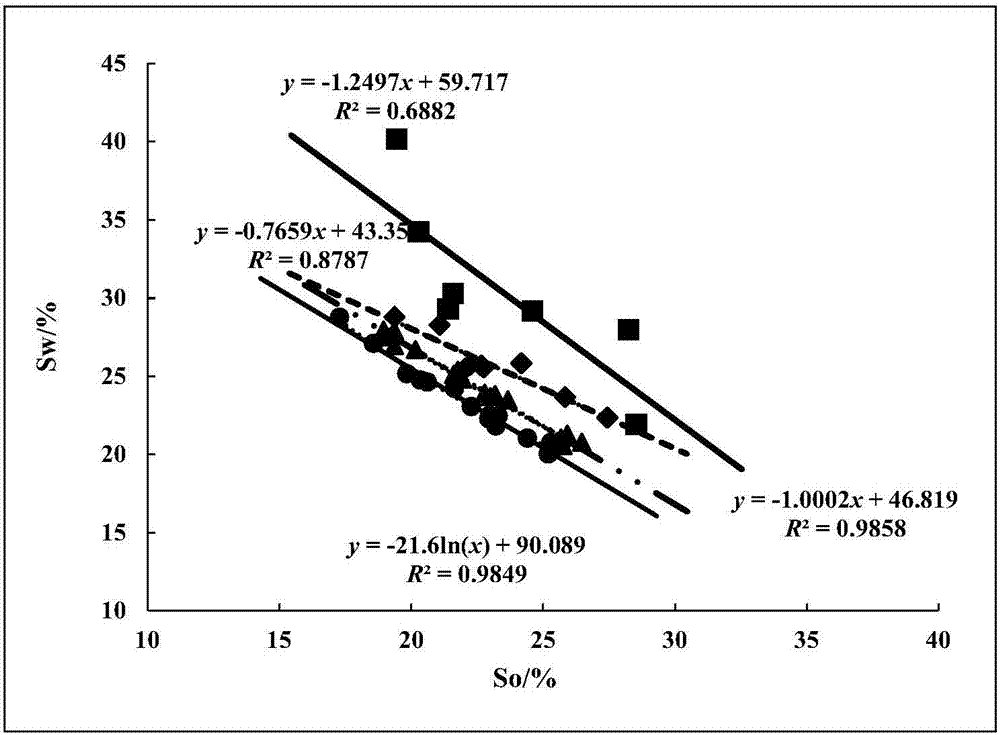

[0032] In the second step, according to the partition results of the first step, take the oil saturation as the abscissa and the water saturation as the ordinate and eliminate the distortion points, and perform linear regression to obtain the slope and intercept;

[0033] According to the partition situation in the first step, then perform linear regression on each district, refer to figure 2 , and then obtain the slope and intercept of the linear fitting curve for each partition as shown in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com