Preparation method of nitrogen-doped nano catalyst adopting double-shell-layer structure

A nano-catalyst and nitrogen-doped technology, applied in the direction of nanotechnology, nanotechnology, structural parts, etc., can solve the problems of high cost and poor stability, and achieve the effects of cost reduction, high oxygen reduction catalytic performance, and uniform catalyst morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

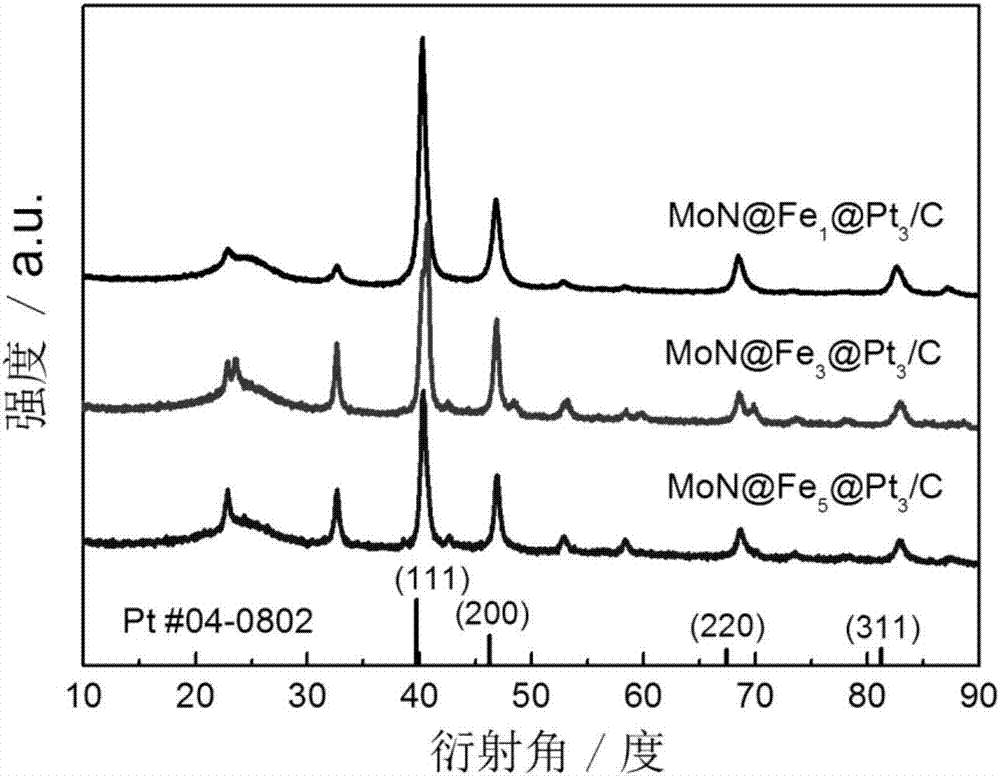

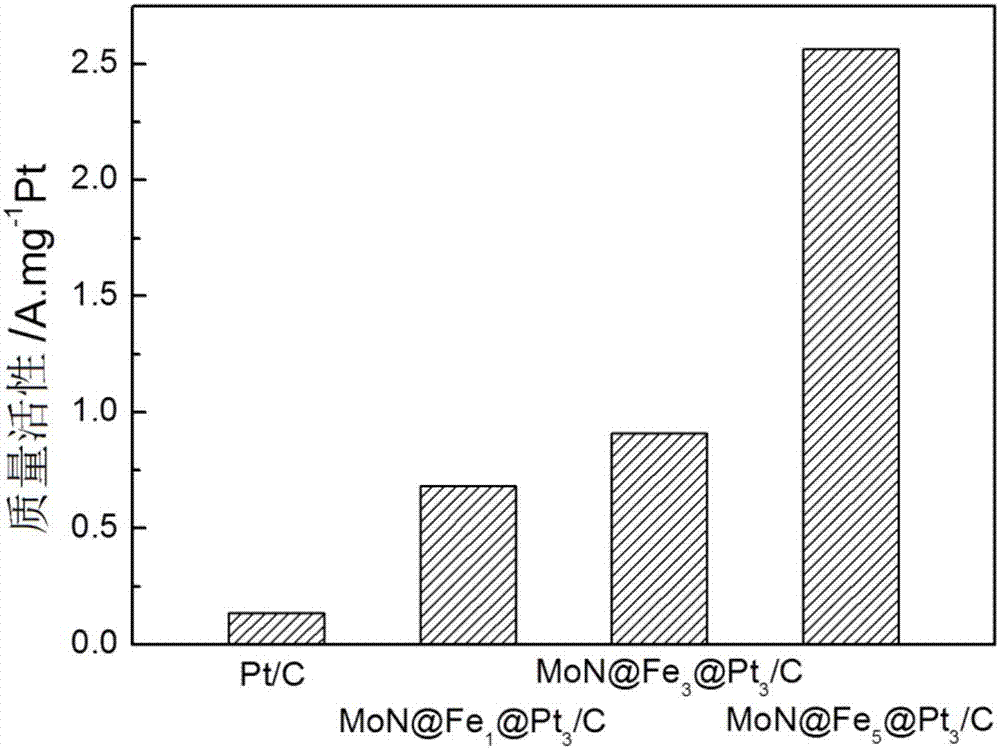

Embodiment 1

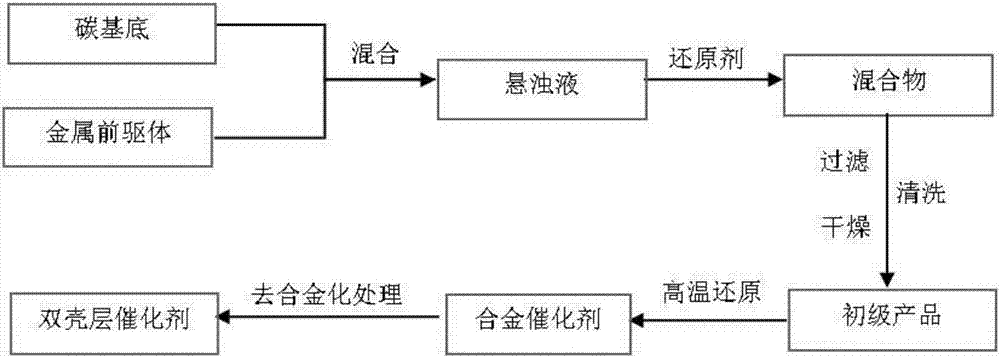

[0026] A preparation method of a nitrogen-doped double-shell structure nano-catalyst, the operation steps are as follows:

[0027] (1) Catalyst reduction: take 2 milliliters of aqueous solution of chloroplatinic acid with a concentration of 42 mg / ml, dissolve 19 mg of ferric chloride and 12 mg of ammonium heptamolybdate in 50 ml of deionized water to obtain a metal precursor solution, then add 200 mg of carbon black to the metal precursor solution, ultrasonically stir and disperse to obtain a suspension, then move it to a constant temperature oil bath at 50 degrees Celsius for magnetic stirring, and then add 27 mg of sodium borohydride for reduction for 24 hours , filtered and washed with deionized water, and the resulting filter residue was vacuum-dried at 60 degrees Celsius for 12 hours to obtain a solid powder, which was the primary product;

[0028] (2) high-temperature calcination of catalyst: the primary product gained in the step (1) is placed in a crucible, puts into a...

Embodiment 2

[0031] A preparation method of a nitrogen-doped double-shell structure nano-catalyst, the operation steps are as follows:

[0032] (1) Catalyst reduction: take 1.7 milliliters of chloroplatinic acid aqueous solution with a concentration of 42 mg / ml, dissolve 48 milligrams of ferric chloride and 11 milligrams of ammonium heptamolybdate in 50 milliliters of deionized water to obtain a metal precursor solution, then add 200 mg of carbon black to the metal precursor solution, ultrasonically stir and disperse to obtain a suspension, then move it to a constant temperature oil bath at 50 degrees Celsius for magnetic stirring, and then add 32 mg of sodium borohydride for reduction for 24 hours , filtered and washed with deionized water, and the resulting filter residue was vacuum-dried at 60 degrees Celsius for 12 hours to obtain a solid powder, which was the primary product;

[0033](2) high-temperature calcination of catalyst: the primary product gained in the step (1) is placed in ...

Embodiment 3

[0036] A preparation method of a nitrogen-doped double-shell structure nano-catalyst, the operation steps are as follows:

[0037] (1) Catalyst reduction: take 1.5 milliliters of chloroplatinic acid aqueous solution with a concentration of 42 mg / ml, dissolve 71 milligrams of ferric chloride and 9 milligrams of ammonium heptamolybdate in 50 milliliters of deionized water to obtain a metal precursor solution, then add 200 mg of carbon black to the metal precursor solution, ultrasonically stir and disperse to obtain a suspension, then move it to a constant temperature oil bath at 50 degrees Celsius for magnetic stirring, then add 37 mg of sodium borohydride for reduction for 24 hours , filtered and washed with deionized water, and the resulting filter residue was vacuum-dried at 60 degrees Celsius for 12 hours to obtain a solid powder, which was the primary product;

[0038] (2) high-temperature calcination of catalyst: the primary product gained in the step (1) is placed in a cr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap