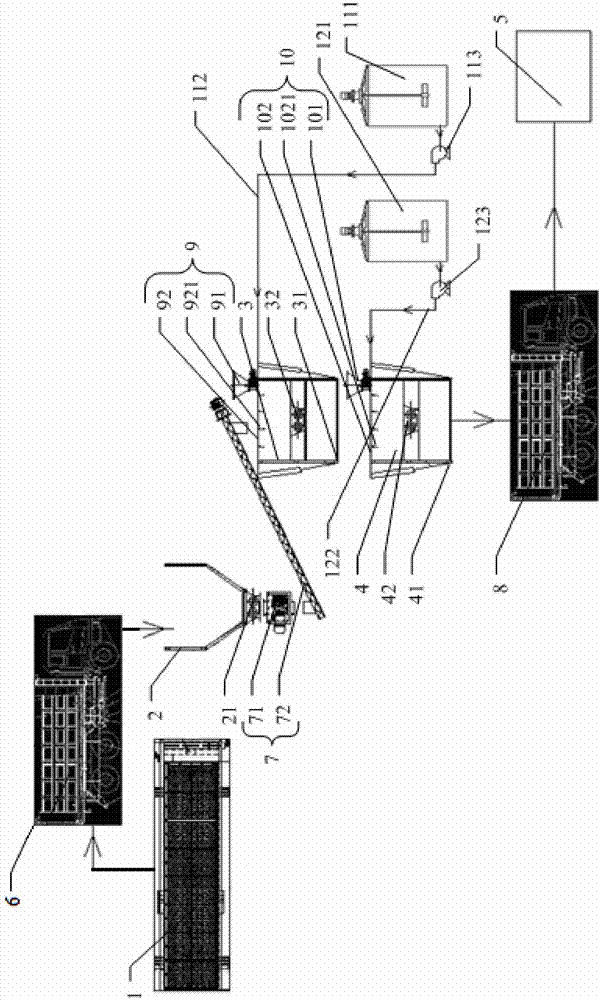

Ex-situ chemical restoration system of polluted soil

A polluted soil, chemical remediation technology, applied in the field of contaminated soil remediation, can solve the problems of damaged equipment, difficult to clean, easy clogging of high-pressure nozzles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

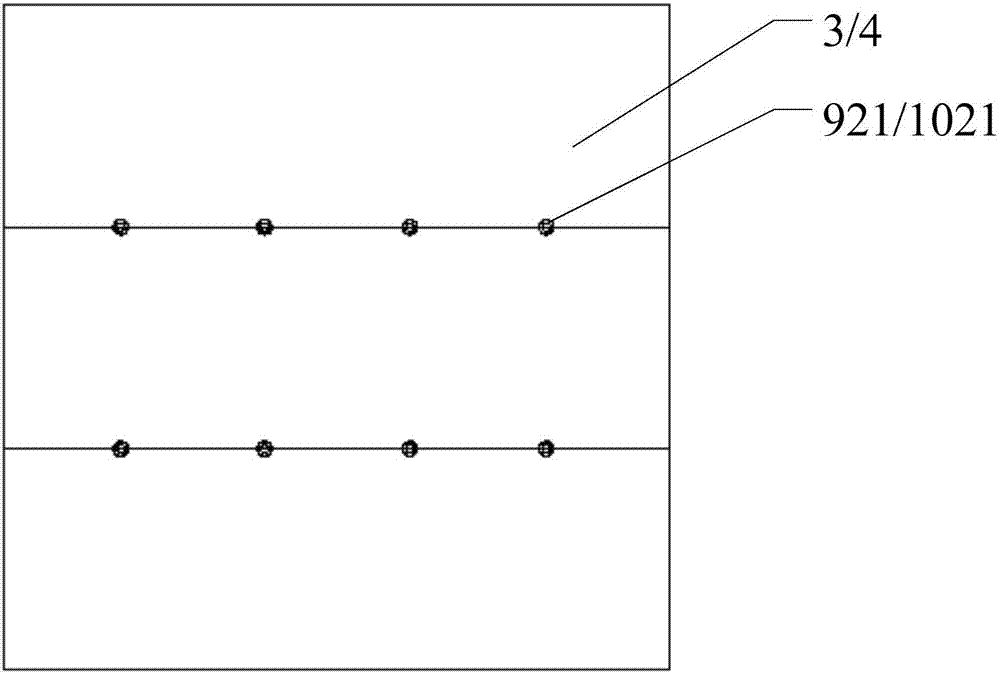

Embodiment 1

[0131] A total petroleum hydrocarbon-contaminated soil is excavated and sent to the pretreatment device, screened and crushed by the ALLU screening and crushing bucket, and then sent to the storage warehouse by dump truck. The storage warehouse has a volume of 5m 3 , the contaminated soil in the storage bin is sent to the primary reactor through the double-screw unloader, the horizontal shaftless screw conveyor, and the inclined shaftless screw conveyor, and the hydrogen peroxide is added to the primary reactor through the first liquid chemical dosing device at the same time And mixed with the polluted soil by a double-helix mixer. The volume of the first-stage reactor is 3000L, and the amount of hydrogen peroxide added is 1% of the mass of the polluted soil. When the amount of polluted soil in the first-stage reactor reaches 2500L, it passes through the second unloading device once. It is unloaded into the secondary reactor, and citrate-complexed iron is added into the seconda...

Embodiment 2

[0133] A certain heavy metal contaminated soil is sent to the pretreatment device after being excavated, screened and crushed by the ALLU screening and crushing bucket, and then sent to the storage warehouse by a dump truck. The storage warehouse has a volume of 5m 3 , the contaminated soil in the storage bin is sent to the first-stage reactor through the double-screw unloader, the horizontal shaftless screw conveyor, and the inclined shaftless screw conveyor. Sodium sulfide solution, dosing bentonite through the first solid agent dosing device and mixing with the contaminated soil through a double-helix mixer, wherein the volume of the primary reactor is 4500L, the amount of sodium sulfide added is 4‰ of the quality of the polluted soil, and the amount of bentonite added It is one ten-thousandth of the quality of polluted soil. When the amount of polluted soil in the primary reactor reaches 3500L, it will be unloaded into the secondary reactor through the second unloading devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com