On-line liquid steel attachment cleaning device for continuous casting and method

A cleaning device and continuous casting billet technology, applied in welding equipment, gas flame welding equipment, metal processing equipment, etc., can solve the problems of difficult to clean the cutting end face, poor use effect, affecting product quality, etc., to reduce the surface Quality risk, reduced cleaning costs, and the effect of a clean and thorough cut

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

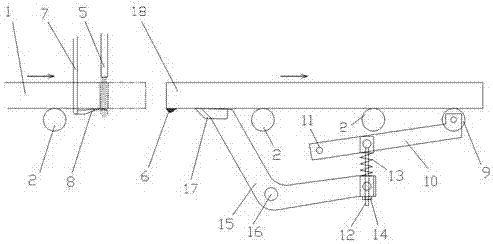

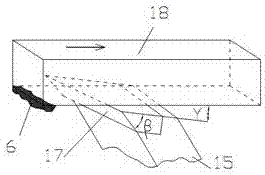

[0029] The on-line cleaning device for continuous casting slab cutting tumor of the present invention includes two parts: a high-pressure nitrogen gas purging part and a mechanical cleaning part. The high-pressure nitrogen purging part and the mechanical cleaning part respectively remove the front and rear cut tumors of the continuous casting slab, and the cleaning process adopts the method of cleaning while cutting on the line.

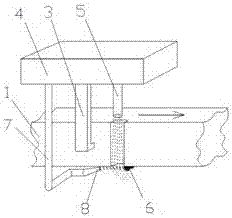

[0030] figure 1 It shows that the continuous casting slab 1 is located above the billet discharge roller table 2, the continuous casting slab clamping plate 3 clamps the continuous casting slab 1 from both sides of the continuous casting slab 1, the flame cutting machine 4 is above the continuous casting slab 1, and the flame cutting machine 4 The cutting torch 5 cuts the continuous casting slab 1 vertically downward.

[0031] figure 1 , 2 It is shown that the high-pressure nitrogen purge part is composed of a high-pressure purge pipe 7 and a blow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com